Sources: Fortera Corp., San Jose, Calif.; CP staff Fortera has formally commenced ReAct concrete binder processing at a facility adjacent to the CalPortland Co. Redding, Calif. cement mill. The Redding ReCarb Plant is North America’s first industrial green cement and carbon dioxide mineralization facility and one of the largest operations in the carbon capture and use class the world over.…

Read MoreTag: carbon capture

Holcim capitalizes on solar power for District of Columbia ready mixed plant

New solar panels at the Holcim US Fort Totten ready mixed plant will ease the Washington, D.C. industrial power load and advance the Chicago-based producer’s goal of running all concrete, cement and aggregate sites with renewable energy by 2030. The installation includes cementitious material silo rooftop and carport solar modules, combining to generate 1,300-1,500 MWh per year of green energy.…

Read MoreFirst Out of the Gate

Blair Block starts up CarbonBuilt-equipped CMU production line Childersburg, Ala.-based Blair Block is the premier operator to adopt the carbon dioxide-capturing and -mineralizing technology of CarbonBuilt, enabling promotion of concrete masonry units whose embodied carbon characteristics are 70-100 percent lower than traditional blocks. The CarbonBuilt technology replaces most of the portland cement typically used in CMU mix designs with a…

Read MoreHolcim backs CO2 mineralizing technology specialist Blue Planet

Sources: Holcim US, Chicago; CP staff Holcim North America has taken a financial position in Blue Planet Systems Corp. of Los Gatos, Calif., joining three other marquee investors that have announced stakes in the carbon capture, use and storage (CCUS) technology developer since 2020: Knife River Corp., Mitsubishi Corp. and Chevron. Their capital supports commercialization of a process that mineralizes…

Read MorePCA offers feds an industry decarbonization reality check

Sources: Portland Cement Association, Washington, D.C.; CP staff Federal policy is vital to accelerate deployment of technologies that can curtail industrial sector carbon dioxide emissions, Portland Cement Association contends in response to the U.S. Department of Energy Advanced Manufacturing Office’s (AMO) “Request for Information on Industrial Decarbonization Priorities.”

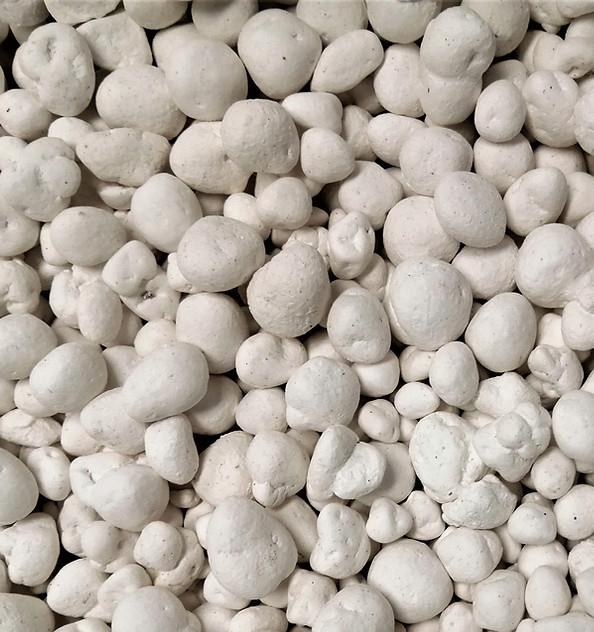

Read MoreMineralized aggregate developer Blue Planet secures $10M commitment

Sources: Blue Planet Systems Corp., Los Gatos, Calif.; CP staff A $10 million funding round positions Blue Planet to advance a carbon capture and utilization system netting concrete-grade synthetic limestone. The Silicon Valley company is approaching commercialization of a process that converts diluted carbon dioxide from fossil fuel-powered electricity generating stations, cement or steel mills, and petroleum refineries to carbonate…

Read MoreOxygen fuels cement producers’ carbon capture venture

Sources: HeidelbergCement AG, Germany; CP staff

The parent companies of Lehigh Hanson Inc., Buzzi Unicem and National Cement Co. have joined a fourth European peer on Cement Innovation for Climate or CI4C, a research corporation investigating the potential of oxygen fuel technology to maximize carbon dioxide capture in portland cement production.

Read MorePartnership scales up carbon dioxide-mineralizing aggregate production

Sources: Kamine Development Corp., Bedminster, N.J.; CP staff

Blue Planet and utility infrastructure specialist Kamine Development have teamed to deploy the former company’s mineralization technology for converting power plant carbon dioxide emissions to a concrete-grade, synthetic limestone. The net CO2-sequestration effect has to potential to offset emissions associated with portland cement production and render a concrete mix designed with the synthetic limestone as carbon neutral or negative.

Read MoreUCLA team demonstrates carbon capture in precast block production

Sources: University of California, Los Angeles; CP staff

A University of California, Los Angeles team in the final round of the $20 million NRG Cosia Carbon Xprize competition has scheduled a February 2020 demonstration of a process yielding precast concrete blocks with carbon dioxide gas from coal-fired power generation. Carbon Upcycling UCLA will stage the 30-day undertaking at the Dry Fork Station near Gillette, Wyo.; members see daily production of up to 10 tons of their CO2ncrete-trademarked units for use in wall construction.

Read MoreIndustry assesses fly ash designation measures, EPA Clean Power Plan

The U.S. House of Representatives passed “Improving Coal Combustion Residuals Regulation Act of 2015,” (H.R. 1734) in a bipartisan 258-166 vote. Sponsored by Rep. David McKinley, (R-WV), it codifies the Environmental Protection Agency’s decision to regulate fly ash and other coal combustion residuals (CCR) under the Resource Conservation and Recovery Act (RCRA) “solid” versus “hazardous” waste provisions.