Sources: Fortera Corp., San Jose, Calif.; CP staff

Fortera has formally commenced ReAct concrete binder processing at a facility adjacent to the CalPortland Co. Redding, Calif. cement mill. The Redding ReCarb Plant is North America’s first industrial green cement and carbon dioxide mineralization facility and one of the largest operations in the carbon capture and use class the world over. It is equipped for annual output of 15,000 tons of ReAct powder, and capture of 6,600 tons of carbon dioxide from a flue stack serving the CalPortland plant calcining phase. On a ton-for-ton basis against portland cement, Fortera measures a 70 percent reduction in carbon emissions tied to ReAct, whose main compound is a rare form of calcium carbonate. The company anticipates deliveries later this quarter—likely supersacks for starters—to concrete producers, who can use ReAct as a supplementary cementitious material in blended binders, or as a full portland cement replacement. ReAct testing and field concrete demonstration candidates include CalPortland ready mixed operations and Vulcan Materials’ Central Concrete Supply business.

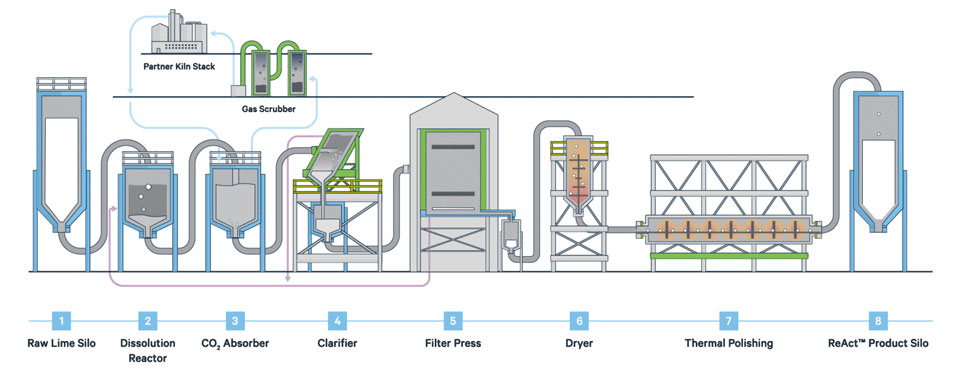

CARBON DIOXIDE TO CEMENT PATHWAY

“Redding is the first of many plants in Fortera’s future as a green cement producer, and achieving this milestone brings the industry that much closer to realizing zero-carbon cement, which is critical for both our continued infrastructure and the health of our planet,” says CEO Ryan Gilliam. “While significant, we recognize this is one step in a much larger effort to reach commercialization globally, and we are committed to scaling our technology using existing infrastructure to mobilize widespread adoption of low and zero-carbon cement.”

“For 132 years, CalPortland has developed resilient and sustainable cement and concrete products. We understand the importance of using science-driven research to continue to develop new and innovative products that will have a positive impact on the future,” adds CalPortland Executive Vice President Steve Regis. “We are excited to partner with Fortera as they develop their new ReCarb technology and congratulate them on the completion of their new facility.”

ReCarb technology reduces carbon emissions throughout the value chain without imposing substantial capital costs and creates a product that is just as effective as ordinary cement, Fortera notes. ReCarb also increases overall product output: When limestone is heated in a kiln to make ordinary cement, nearly half is lost as CO2. Mineralizing calcining phase emissions through ReCarb yields a ton of green cement for every ton of limestone feedstock used. Further, ReCarb reduces energy consumption by using a lower kiln temperature and creates a path to zero CO2 cement when processed with renewable energy-powered equipment.

Related article

Lehigh Redding moves to mill SCM from CO2-rich kiln emissions