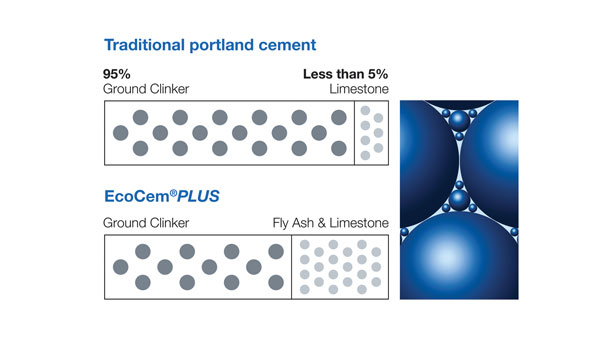

Lehigh Hanson Inc. is extending its recently launched, carbon-wise EcoCem portland-limestone cement series with EcoCem PLUS, milled at the Lehigh Cement Edmonton Plant and Terminal and debuting in Alberta, Saskatchewan and Manitoba. Finished by inter-grinding cement clinker, fly ash, limestone and gypsum, the material outperforms traditional CSA Group-grade (High Sulphate Limestone blend) HSLb-20F powder in resisting sulphate attack, common in…

Read MoreTag: fly ash

Titan’s Separation Technologies proves new fly ash reclamation process

Sources: Titan America LLC, Norfolk, Va.; Separation Technologies LLC, Roanoke, Va.; CP staff Separation Technologies (ST) has commissioned its first industrial scale plant engineered to reclaim fly ash from coal ash impoundment basins. A pilot facility at the Talen Energy Brunner Island Steam Electric Station in York Haven, Pa. combines the Titan America subsidiary’s new proprietary drying and screening system…

Read MoreFly ash use in concrete up slightly; overall ash recycling rate down

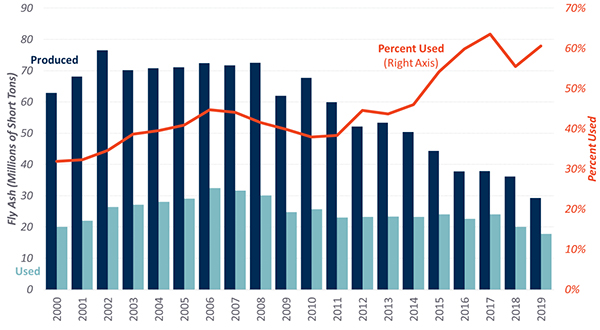

Fifty-two percent of the coal ash produced during 2019 was recycled, marking the fifth consecutive year that more than half of the power generating station byproduct in the United States was beneficially used rather than disposed. The volume of fly ash used in concrete, 12.6 million tons, marks a 1 percent increase over 2018 consumption. Year-over-year use of fly ash…

Read MoreFly ash use in concrete up slightly; overall ash recycling rate down

Source: American Coal Ash Association, Farmington Hills, Mich. Fifty-two percent of the coal ash produced during 2019 was recycled, marking the fifth consecutive year that more than half of the power generating station byproduct in the United States was beneficially used rather than disposed. The volume of fly ash used in concrete, 12.6 million tons, marks a 1 percent increase…

Read MoreSalt River unearths additional 300K/year Class F ash processing potential

Sources: Salt River Materials Group, Phoenix; CP staff

One of the West’s principal Class F fly ash sources continues to build out processing and blending capacity in response to diminished supplies of the material stemming from coal-fired power generating station retirements.

Read MoreSalt River poised to add 250K tons to Intermountain Class F ash supply chain

Sources: Salt River Materials Group, Phoenix; CP staff

Salt River Materials Group (SRMG) and electricity operator PacifiCorp have entered a Fly Ash Marketing Agreement covering Rocky Mountain Power’s Huntington plant in Utah, located about 150 miles southeast of Salt Lake City. It provides exclusive rights to process and market the facility’s ASTM C618 Class F fly ash, and becomes the ninth such agreement in an SRMG management and marketing portfolio spanning Utah, Arizona and New Mexico coal-fired generating stations.

Read MoreSalt River increases blending capacity for performance Class F ash substitute

Sources: Salt River Materials Group, Phoenix; CP staff

Salt River Materials Group has built a powder blending facility and expanded loadout capabilities at its Tucscon Terminal, responding to energy market forces hampering consistent supply of high quality fly ash for Arizona concrete customers. Located within the Tucson Electric Power Sundt Generating Station, the new operation blends ash from multiple sources plus a Type N natural pozzolan for a finished powder meeting ASTM C1697, Standard Specification for Blended Supplementary Cementitious Materials requirements. The material is dubbed “Tucson Pozzolan” and expands supply of a performance Class F fly ash substitute.

Read MoreCR Minerals confirms plant expansion tripling natural pozzolan output

Sources: CR Minerals Co., Fort Worth, Texas; CP staff

The largest processor of raw natural pozzolans for performance mixes and Class F fly ash substitution will invest more than $10 million over a three-year period to increase capacity at a Pueblo, Colo. operation dedicated to concrete and oil & gas grades. CR Minerals aims to more than triple production capabilities of its Tephra NP, OG and (remediated fly ash) RFA pumiceous materials.

Read MoreCharah lands 2M-ton ash processing contract in Southeast

Sources: Charah Solutions Inc., Louisville, Ky.; CP staff

A Southeastern utility has tapped Charah Solutions for a Closure by Removal impoundment project encompassing upward of 100 acres of ash deposits at a coal-fired power station that was retired in 2015. Work will include installation of environmental controls plus rail infrastructure improvements and extension, along with loadout area construction. Over a multi-year contract, Charah anticipates processing of 2 million-plus tons of impounded material for beneficial use as concrete-grade fly ash, while preparing the former pond acreage to be restored as usable property.

Read MoreChemists pinpoint green method to separate coal ash minerals, elements

Source: Elixsys Inc., Aiken, S.C.

Chemical specialist Elixsys reports successful laboratory extraction of industrial-grade compounds from power generating stations’ coal combustion products (CCP). Through methods exhibiting “zero waste and environmental impact” and marketing agreements in place or progress, the company plans to bring finished materials to construction and industrial supply chains.

Read More