An investment upward of $100 million will raise clinker and limestone grinding capacity while improving logistics for the Holcim US Ste. Genevieve (Mo.) Cement Plant, located south of St. Louis along the Mississippi. In addition to the largest single-kiln line in the world, the facility is equipped with sophisticated emissions controls, fully automated quality control laboratories, plus barge and rail…

Read MoreTag: limestone

DOE funds cement pre-calcining heat demonstration

The U.S. Department of Energy (DOE) has awarded Pasadena, Calif.-based Heliogen $4.1 million to demonstrate a concentrated solar power (CSP) process for heating limestone to 950°C, applicable to the calcining phase in portland cement production. CSP technologies deploy mirrors to beam sunlight onto a receiver, and can be used to deliver heat for energy-intensive industrial processes or generate electricity using…

Read MoreEnergy Department funds cement pre-calcining heat demonstration

Sources: U.S. Department of Energy; CP staff The Department of Energy (DOE) has awarded Pasadena, Calif.-based Heliogen $4.1 million to demonstrate a concentrated solar power (CSP) process for heating limestone to 950°C, applicable to the calcining phase in portland cement production. CSP technologies deploy mirrors to beam sunlight onto a receiver, and can be used to deliver heat for energy-intensive…

Read MoreNational Cement doubles flagship mill capacity, calms CO2 emissions factor

Executives of National Cement Company of Alabama Inc., parent National Cement Company Inc., and ultimate parent Vicat Group, Paris, staged a late-July dedication of a new production line at their Ragland, Ala. plant. A Kiln 2 ribbon cutting capped a two-year, $300 million project that brings annual Ragland capacity above 2 million short tons and assures a sharp reduction in…

Read MoreBreakthrough Binder

Investors targeting reduction of the carbon dioxide emissions factor in portland cement and concrete have focused on methods capturing, using or storing the greenhouse gas, plus new means of generating the high temperatures fossil fuel-fired cement kilns need to convert limestone and other raw feeds to clinker. A Longmont, Colo. startup has garnered backing for technology paving a different path…

Read MoreInvestors steer Prometheus Materials’ microalgae-derived binder to market

Sources: Prometheus Materials, Boulder, Colo.; CP staff Prometheus Materials has closed an $8 million initial venture capital funding round to support commercialization of precast elements and a ready mixed material designed with a bio-cement similar to the binder coral and oysters use to form reefs and shells. When mixed with sand and gravel or stone, the bio-cement offers what the…

Read MoreLafargeHolcim, Lafarge Canada spotlight low-carbon mix designs

Traditionally carbon intensive, the cement industry is seeing a significant change in how specifiers, architects and customers are looking at building materials through the lens of environmental impact. In response to demand for products with a lower carbon footprint, Lafarge and LafargeHolcim concrete operations in Canada and the United States have partnered to raise awareness that environmentally-friendly, cement-based products are…

Read MoreLow carbon LC3 binder steers Sika’s next admixture chapter

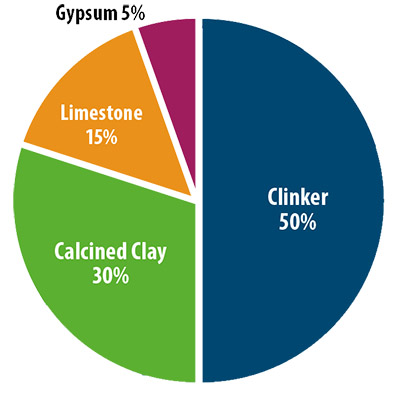

The Swiss parent company of New Jersey-based Sika Corp. will tailor a new family of concrete admixtures and cement additives around the chemistry and behavior of an emerging binder known as LC3, or Limestone Calcined Clay Cement. Through work with Sika AG and peers, Swiss Federal Institute of Technology officials view the material as a means of carbon footprint reduction…

Read MoreLehigh Cement sets new watermark for clinker + limestone + ash blends

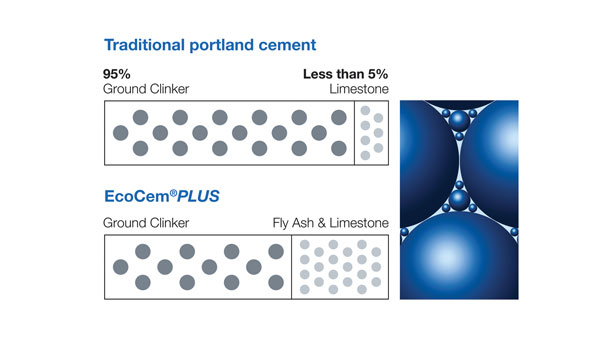

Lehigh Hanson Inc. is extending its recently launched, carbon-wise EcoCem portland-limestone cement series with EcoCem PLUS, milled at the Lehigh Cement Edmonton Plant and Terminal and debuting in Alberta, Saskatchewan and Manitoba. Finished by inter-grinding cement clinker, fly ash, limestone and gypsum, the material outperforms traditional CSA Group-grade (High Sulphate Limestone blend) HSLb-20F powder in resisting sulphate attack, common in…

Read MoreMineralized aggregate developer Blue Planet secures $10M commitment

Sources: Blue Planet Systems Corp., Los Gatos, Calif.; CP staff A $10 million funding round positions Blue Planet to advance a carbon capture and utilization system netting concrete-grade synthetic limestone. The Silicon Valley company is approaching commercialization of a process that converts diluted carbon dioxide from fossil fuel-powered electricity generating stations, cement or steel mills, and petroleum refineries to carbonate…

Read More