Sources: Advanced Construction Robotics, Pittsburgh; CP staff

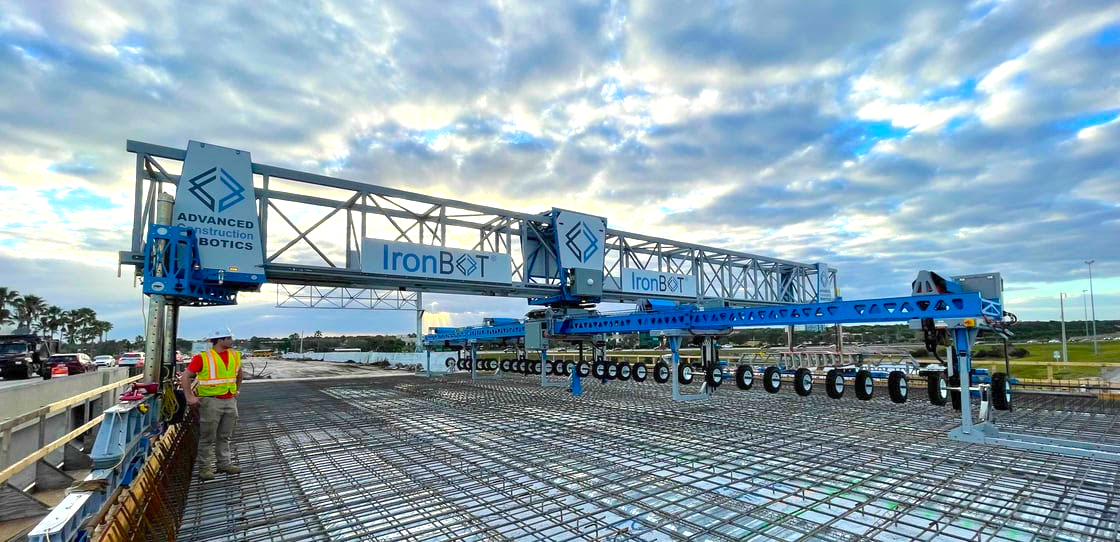

Advanced Construction Robotics (ACR) arrived in Las Vegas for ConExpo-Con/Agg with its second workhorse for reinforced concrete construction: IronBOT, equipped to lift, carry and place up to 5,000-lb. bundles in transverse or longitudinal orientation and relieve crew members of routine heavy lifting. IronBOT joins TyBOT, the rebar-tying robot that put ACR on the map and has garnered buy in from contractors, agencies and labor interests. When deployed in tandem, the robots can reportedly net a 50 percent time savings in rebar installation schedules.

“We are confident the combination of TyBOT and IronBOT generates a disruptive technology, meaning the time and cost savings are so significant on a job that it will disrupt the way our industry installs reinforcing steel,” says ACR Founder and Executive Chairman Stephen Muck.

The first IronBOT completed an inaugural project in February on the Port St. Lucie West Boulevard Bridge in Florida, alongside Shelby Erectors Inc. crews. The originally estimated rebar installation window was 14 days. By augmenting Shelby’s crew with the BOT Bundle, the same amount of work was completed in only seven days. During the pilot, IronBOT placed 147,032 lbs. of steel while a TyBOT companion completed 58,068 ties over 6.5 production shifts. As ACR Integration Partner, Shelby Erectors has been boosting crew productivity with TyBOT for over two years.

Related article

Analytics, carbon, electric power, hydrogen frame record ConExpo-Con/Agg