An 850-ft. mixed-use tower has rapidly climbed into the Seattle skyline on the strength of a unique core wall system with requisite volumes of high performance concrete but no conventional rebar. Topped out in early August, Rainier Square Tower marks the debut of what Seattle engineer Magnusson Klemencic Associates (MKA) dubs the Concrete-Filled Composite Plate Shear Wall (CPSW) system.

Read MoreCategory: TECHNICAL TALK

Master Builders mixes mortar for Manhattan monarchs

Material science behind lightweight concrete and self-consolidating mixtures yields a principal element of the Monarch Sanctuary, a 15-ft. “vertical butterfly meadow” prototype on display at the Cooper Hewitt Smithsonian Design Museum, New York City.

Read MoreTopcon raises concrete paving bar through Millimeter GPS

Concrete paving is pretty complex and achieving quality, long-lasting results requires skill, the right equipment, and advanced technology. At its root, pavement is an outdoor floor … a hardscape surface covering that is driven or walked on. One of the major advantages of concrete pavements is they are typically stronger and more durable than other types of surfaces. They also can be grooved to provide a tough, skid-resistant surface. A notable disadvantage is that they typically can be more time-consuming to construct. Thus, concrete contractors have turned to technology for production-enhancing efficiencies and improved results.

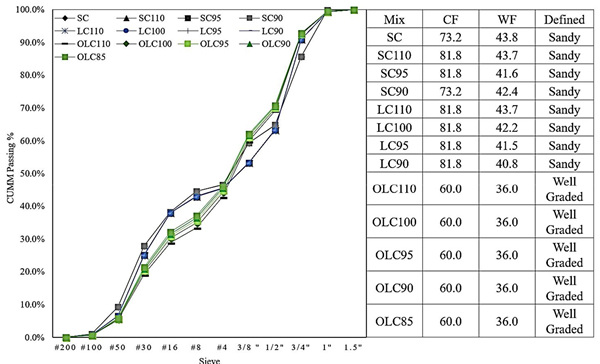

Read MoreTRB 2019: Reduce portland cement content by optimizing gradation

Materials are the critical component of durable transportation infrastructure, and as such got strong coverage at the 99th annual Transportation Research Board meeting earlier this year in Washington, D.C. There, some 12,000 delegates audited presentations in over 800 sessions, which addressed many aspects of transportation design, construction and policy, and encompassed infrastructure built with cast-in-place concrete.

Read MoreTRB 2019: Nanotechnology boosts performance of cementitious grouts

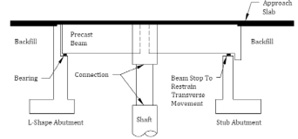

Precast concrete products were on the agenda of the 99th annual Transportation Research Board meeting in January in Washington, D.C. Over 12,000 delegates heard presentations in 800-plus sessions addressing multimodal transportation policy and construction practice, including materials and design involving precast/prestressed products. Concrete Products was there and we present this report on new research in precast structures and methods. We will look at TRB 2019 research in cast-in-place concrete later this year. The 100th meeting of TRB will take place January 12-16, 2020. For more information, visit www.trb.org.

Read MorePrecast/prestressed pavement, deck panels drive research at TRB

The annual Transportation Research Board meeting in January is one of the highlights of the pavement and bridge research community. This year’s event drew over 13,000 transportation engineers and specialists from the United States and other countries to Washington, D.C. Delegates could audit 5,000-plus presentations in over 800 sessions addressing topics in transportation construction, including projects based on precast/prestressed concrete structures and methods. Concrete Products was there and this month presents a report on new research findings in precast/prestressed research at TRB 2018. We looked at ready-mixed and cast-in-place concrete previously, see March 2018, pages 54-57. For more information, visit www.trb.org.

Read MoreTRB: Albedo change study quantifies role in climate change; PCC overlays perform

The 97th annual meeting of the Transportation Research Board in January drew 13,000-plus transportation engineers and specialists from across the country, and around the world to Washington, D.C. More than 5,000 presentations in over 800 sessions addressed topics in multimodal transportation, including materials and design involving ready mixed concrete and precast/prestressed products. Concrete Products was there and this month presents a report on new research findings in cast-in-place concrete. We’ll look at precast/prestressed related research from TRB 2018 in an upcoming issue. For more information, visit www.trb.org.

Read MoreUniform particle size coal ash: Essential for future concrete applications

The decline in coal for energy has reduced available fly ash supply to the concrete industry and generated a significant increase in finished product variability, which has led to a sharp rise in material costs for high profile projects such as One World Trade Center, New York City.

Read MoreABCs of TRB: Accelerated Bridge Construction ideal for precast/prestressed

Technical papers involving accelerated bridge construction and precast/prestressed concrete products were among the 5,000-plus presentations in more than 800 sessions at the 96th annual meeting of the Transportation Research Board. More than 13,000 transportation engineers and specialists from across the country—and around the world—journeyed to Washington, D.C., earlier this year for TRB 2017, and Concrete Products was among them.

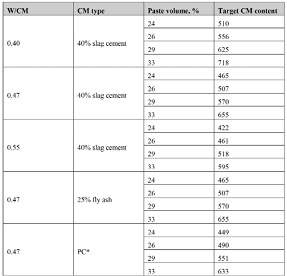

Read MoreCut costs, carbon, and boost durability by dropping cementitious minimums

by tom kuennen

Read More