by tom kuennen

The 96th annual meeting of the Transportation Research Board in January in Washington, D.C., drew over 13,000 transportation engineers and specialists from across the country, and around the world. More than 5,000 presentations in over 800 sessions addressed topics in multimodal transportation, including materials and design involving ready-mixed concrete and precast/prestressed products. Concrete Products was there and this month presents a report on new research findings in ready-mixed and cast-in-place concrete. We’ll look at precast and precast/prestressed research at TRB 2017 in an upcoming issue. For more information, visit www.trb.org.

NO NEED TO SPECIFY MINIMUM CEMENTITIOUS MATERIALS CONTENT

There is no need to specify minimum cementitious material contents in concrete mixes, as overspecification increases costs and a project’s carbon footprint, while potentially compromising performance, say Karthik H. Obla, Ph.D, P.E., Rongjin Hong and Colin L. Lobo in their peer-reviewed paper, Should Minimum Cementitious Contents for Concrete Be Specified?

Minimum cementitious contents are commonly specified in projects, the authors say. “In the U.S. many state highway agencies specify a minimum cement content between 550 and 600 lb./yd.3 for slip-form pavement mixtures,” they write. Furthermore, most state highway agencies also establish classes of concrete for various elements in transportation construction projects and these classes of concrete are typically defined by minimum content of cementitious materials among other parameters, they add.

An industry survey conducted in 2014 revealed that minimum cementitious content was indicated in 46 percent of all project specifications. However, consensus-based industry standards in the United States—for example, from the American Concrete Institute—don’t include requirements for minimum cementitious materials content for concrete mixtures for the most part, Obla, Hong and Logo state.

Minimum limits on cementitious materials specified by state highway agencies typically exceed the quantity required for intended performance, such as workability, strength and durability, they say. “This results in increased cost, a higher carbon footprint, and often negatively impacts the performance of these concrete mixtures. The performance implied or intended by the minimum cementitious material content is most often not clear or enforceable.”

Also, minimum cementitious materials (CM) limits restrict mixture optimization for performance, and as a result there is little incentive for concrete producers and contractors to become more knowledgeable about the ingredient materials and mixtures.

“Specifications that include these requirements do not allow concrete producers and contractors to target lower average strengths by reducing standard deviation through improved concrete quality and as a result, they do not provide any incentive for investing in improved quality management systems,” Obla, Hong and Logo report, thus impeding an evolution toward performance-based specifications.

On the other hand, they note three possible reasons for specifying a minimum cementitious content:

- It provides assurance that a low water-to-cementitious materials ratio (w/cm) is attained, even if good control of the mixing water content is not exercised;

- It ensures there is enough paste to fill the voids between the aggregates and provide adequate workability; and,

- It offers corrosion protection by chemically binding the chlorides and the carbon dioxide that penetrate the concrete.

They note that at any given w/cm, increasing cement contents lead to similar compressive strengths and carbonation rates, but also higher absorption and chloride penetration. A mixture with higher cement content had increased chloride threshold concentration to initiate corrosion, but this benefit was offset by higher level of chloride penetration that could cause the initiation of corrosion of reinforcement.

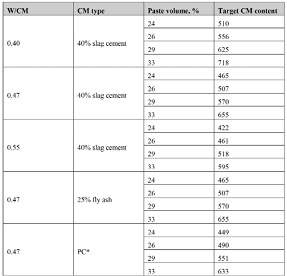

Obla, Hong and Logo examined the influence of the cementitious content on concrete performance at specific water-to-cementitious materials ratios. The experimental variables studied include w/cm ranging from 0.40 to 0.55, mixtures containing portland cement only, and mixtures containing 40 percent slag cement or 25 percent fly ash.

Concrete performance was evaluated through laboratory tests on workability, strength and durability. The results show that at a given w/cm, a higher cementitious content results in higher paste volumes and poorer concrete performance. They found:

- Higher CM contents increased the mixing water demand of concrete. For a given w/cm, increasing CM content resulted in similar compressive strengths, but increased chloride penetrability, increased initial sorptivity and greater length change due to drying shrinkage. The reduced concrete performance of the mixtures with higher CM contents is due to the higher paste volumes. “These results clearly show that at a given w/cm requiring a higher CM content is counterproductive as it leads to poorer concrete performance,” the authors write.

- If the strength and durability requirements for the project are defined, there is no technical basis for specifying the minimum CM content. Instead, workability can be evaluated by test pours or documentation of successful past field history.

- If the main purpose of specifying a minimum CM content is to get assurance of a low w/cm, it’s better to specify an appropriate compressive strength, which is a better indicator of w/cm.

- In summary, moving to a performance based specification facilitates removing the minimum CM content requirement in specifications. “Based on these results the value of maintaining minimum cementitious content requirements in project specifications is questioned,” the authors conclude.

|

|

| TABLE: Obla, Hong and Logo |

RESEARCHERS: USE ROLLER COMPACTED CONCRETE FOR LOW-COST PAVEMENTS

Roller-compacted concrete is suitable for producing relatively low-cost roadways compared to asphalt or conventional concrete pavements, say M. Shabbir Hossain, Ph.D., P.E., and Celik Ozyildirim, Ph.D., P.E., Virginia Transportation Research Council, in their technical paper, Investigation of Properties of Roller-Compacted Concrete for Use in Pavements.

“RCC is a stiff mixture of aggregate, cementitious materials, and water with zero slump,” say Hossain and Ozyildirim. “RCC is consolidated or compacted in the fresh state using a roller with or without vibration [and] is typically placed with asphalt paving equipment in 4- to 8-in. thicknesses for pavement application.”

RCC has gained the attention of the paving industry in recent years because of its history of low-cost, rapid construction, satisfactory early and ultimate strengths, and durable performance, they write. In order to better utilize RCC, the Virginia Department of Transportation conducted a lab study to develop guidelines for its use in the field. Mixtures from two pavement projects in Virginia (Stafford and Richmond) were tested in the laboratory and used different locally available materials.

“RCC mixtures were successfully produced using locally available materials, and their properties were measured,” write Hossain and Ozyildirim. “These mixtures achieved a compressive strength around 5,000 psi in 28 days and had properties similar to those of conventional hydraulic cement concrete in terms of compressive strength, modulus of elasticity, modulus of rupture, splitting tensile strength, permeability, resistance to cycles of freezing and thawing, and acceptance.”

All of these factors make RCC suitable for producing relatively low-cost roadways compared to asphalt or conventional concrete pavements, the authors say. “However, such a roadway may lack the smoothness required for high-speed corridors and can suffer raveling and cracking,” they write. “Diamond grinding or an overlay may be used, if necessary, to achieve smoothness. For slow vehicles [as in a freight transfer yard], a high degree of smoothness may not be required. An asphalt overlay may remedy the smoothness and raveling issues; however, cracks and control joints may reflect through the asphalt layer. Nevertheless, a composite pavement of RCC with asphalt overlay may provide a cost-effective, long-lasting pavement system.”

Hossain and Ozyildirim conclude:

- Local materials from the VDOT-approved source list were successfully used to produce two RCC mixtures in accordance with the requirements of the special provision. In both cases, 28-day compressive strengths were around 5,000 psi with a standard deviation of 880 psi for cylinders prepared in accordance with ASTM C1435 with a vibrating hammer.

- RCC properties and typical relationships among compressive strength, tensile strength, modulus of rupture, and modulus of elasticity are similar to those of conventional hydraulic cement concrete.

- Modulus of rupture was about 36 percent higher than the associated splitting tensile strength for a mixture used in the Stafford project. Splitting tensile strength tests are easier to conduct and could be used to verify modulus of rupture values used for pavement thickness design.

- The minor variation in water content, within 1 percent of optimum moisture content, had minimal effect on the strength of RCC in a laboratory investigation.

- High fines (passing No. 200 sieve) contents, although within specification limits, result in lower compressive strength compared to lower fine contents. All mixtures with various fine contents could be satisfactorily compacted.

- The use of Class F fly ash at 15 percent and 25 percent by weight of cement did not adversely affect early strength development.

|

Mixture proportions for the Virginia Stafford and Richmond roller-compacted concrete mixes (lb./yd.) |

|

PURE HYDRATED ALUMINA CAN FORESTALL ALKALI-SILICA REACTIVITY

Pure hydrated alumina as a cement substitute can quell alkali-silica reactivity (ASR) in cured concrete, say Tiffany Szeles, Farshad Rajabipour and Shelly Stoffels, The Pennsylvania State University, State College, Pa., and Jared Wright, Walker Restoration Consultants, Seattle, in their technical paper, Mitigation of Alkali-Silica Reaction by Al(OH)3 [alumina].

“Recent trends and forecasts on availability of fly ash and slag for use in concrete suggest a need to seek reliable alternative options for mitigation of alkali-silica reaction (ASR),” the authors write. “One such option may be aluminum-based admixtures.”

Past studies have shown that supplementary cementitious materials (SCMs) that contain alumina (Al2O3) are more effective at mitigating ASR than SCMs purely rich in silica (SiO2), they say, citing their research on pure hydrated alumina, Al(OH)3 as a cement replacement to isolate its role in ASR mitigation. Their objectives were to determine if pure hydrated alumina can successfully mitigate ASR, and investigate five hypothesized mechanisms by which it may mitigate ASR.

To determine if Al(OH)3 can mitigate ASR, length change measurements per ASTM C1293 were conducted on concrete prisms. Based on their tests, Szeles, Wright, Rajabipour and Stoffels concluded pure hydrated alumina forestalled ASR by reducing pH and alkalis in concrete pore solution, consuming and reducing dissolved Ca and portlandite, and most of all, reducing silica dissolution and damage to aggregates at high pH. Less functional were its altering the composition of ASR gel and creating innocuous gels, and reducing water and ion transport by reducing porosity and pore size of cement paste.

FLY ASH CAN MINIMIZE DEICER DAMAGE IN PCC PAVEMENTS

Fly ash can reduce deicer damage to concrete pavements by suppressing formation of expansive calcium oxychloride, say Prannoy Suraneni, Vahid J. Azad, O. Burkan Isgor, and Jason Weiss, Oregon State University School of Civil and Construction Engineering, in their peer-reviewed paper, Use of Fly Ash to Minimize Deicing Salt Damage in Concrete Pavements.

|

| Alumina works: scanning electron microscope images of a highly degraded 100 percent ordinary portland cement (OPC) ASTM C1293 concrete prism at 630 days (left, corresponding to 0.2 percent linear expansion), and an intact 80 percent OPC/20 percent Al(OH)3 concrete prism at 900 days (right, corresponding to 0.04 percent expansion). MICROGRAPHS: Szeles, Wright, Pajabipour, Stoffels |

“Premature damage has been observed at the joints in numerous concrete pavements where calcium chloride and magnesium chloride deicing salts have been used,” the authors say. “This damage occurs due to a reaction between the deicing salt and the calcium hydroxide in the hydrated cement paste.”

This reaction leads to the formation of an expansive product known as calcium oxychloride, they write. “The use of supplementary cementitious materials as a replacement for cement has been proposed to reduce the calcium hydroxide that is available in the mixture to react with the deicing salts,” Suraneni, Azad, Isgor, and Weiss say. “Reducing the calcium hydroxide can reduce the amount of calcium oxychloride that forms.”

In this study, mixtures representative of paving-grade concrete were made with cements and fly ashes from across the country. Calcium hydroxide amounts were determined using thermogravimetric analysis and calcium oxychloride amounts were determined using low-temperature differential scanning calorimetry.

Various replacement levels of fly ash demonstrated that the main influence on the amounts of calcium hydroxide and calcium oxychloride that form is the replacement level of fly ash. Their study found that 40 percent replacement of fly ash should be sufficient to limit damage due to calcium oxychloride formation in well over 90 percent of the concrete mixtures. “Fly ash replacement is also known to cause a significant reduction in chloride diffusivity, especially at later ages, this would further reduce damage by reducing chloride ingress,” Suraneni, Azad, Isgor and Weiss report.

They concluded that a prescriptive specification requiring 35 percent cement replacement by volume with fly ash will reduce the damage due to calcium oxychloride formation. They also proposed a performance specification to limit the calcium oxychloride formation to below 15 g/100 g paste.

|

| Examples of joint damage in concrete pavements; damage due to chloride deicers reacting with calcium hydroxide in portland cement concrete to form expansive calcium oxychloride can be quelled by higher substitutions of fly ash for cement. IMAGES: Suraneni, Azad, Isgor and Weiss |