Martin Engineering arrived at 2024 World of Concrete with the MHF-1500 Brushless Concrete Form Vibrator, its design responding to precast producer requests for a versatile, dependable device. Attention to the needs of modern precast operations, along with months of designing and testing, yielded a powerful, portable vibrator that is simple to service in-house.

“Traditionally, this type of motor is universal AC with internal brushes like a DC brushed motor,” says Martin Engineering Global Engineering Manager of Flow Aids Travis Miller. “Those create heat if used on any high-duty cycle application that drives them to failure. By going AC to AC, we can eliminate the brushes and reduce the heat build-up.”

“The sheer size and weight of some precast forms can be demanding on vibrators, so powerful and consistent performance is key,” he adds. “In our research, we found that the difference in power needs between the construction site and the shop were largely the same.”

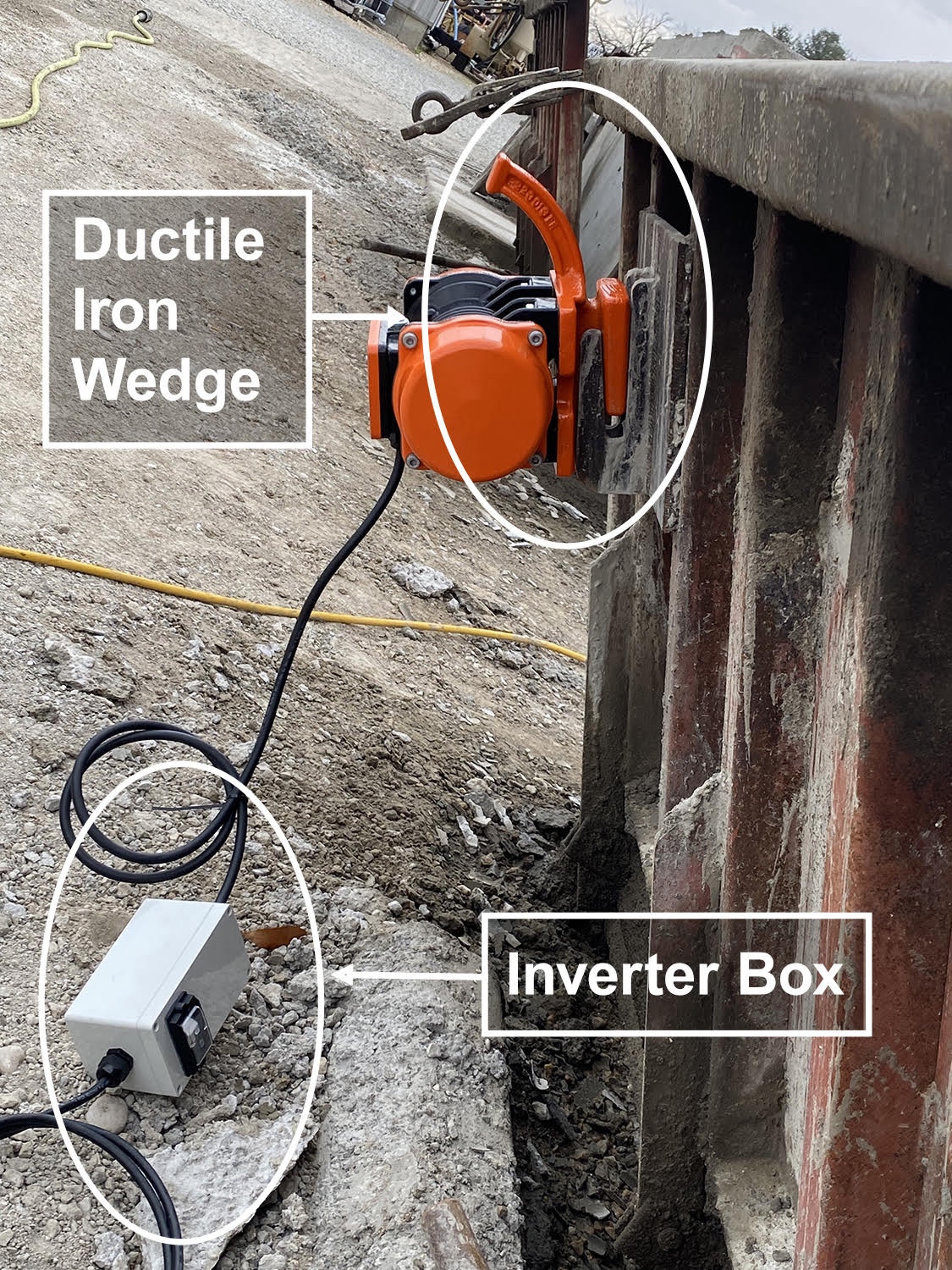

The MHF-1500’s external VFD/Inverter converts single-phase 110-120V 60Hz power to three-phase 230V, 100Hz power in the electric rotary motor, which runs at 6,000 rpm to produce 1,500 pounds (680 kg) of force. This allows for a brushless environment where magnetic fields rotate in space for the rotor to follow; a drastic lowering of heat output reduces wear and tear on internal components and extends the motor’s operating life.

The whole unit is sealed in a totally enclosed, non-ventilated aluminum housing rated International Protection Marking (IP) 66 and National Electrical Manufacturers Association 4. Seals comply with North American and EU standards. Durable O-rings between the end caps and the housing retain the tight seal, even during pressure washing. The casing can be opened for easy maintenance in-house. By removing the weight covers, operators can adjust the vibratory unbalance to the required force needed for the application. Each MHF-1500 features oversized and permanently lubricated roller bearings contained in sealed ductile iron housings, adding to the unit’s long service life. — Martin Engineering, Neponset, Ill., 309/852-2384 or 800/544-2947; www.martin-eng.com