Sources: CarbonCure Technologies, Halifax, Nova Scotia; Heirloom Carbon Technology, Brisbane, Calif.; CP staff

CarbonCure Technologies and its concrete producer licensees will mineralize and permanently store atmospheric carbon dioxide from Heirloom Carbon Technology Direct Air Capture (DAC) assemblies under an agreement through early 2025. The plan advances the DAC-to-concrete storage pathway demonstrated earlier this year at the Central Concrete Supply headquarters plant in San Jose, Calif. CarbonCure-equipped concrete producers will provide a CO2 end use enabling Heirloom to scale its DAC technology.

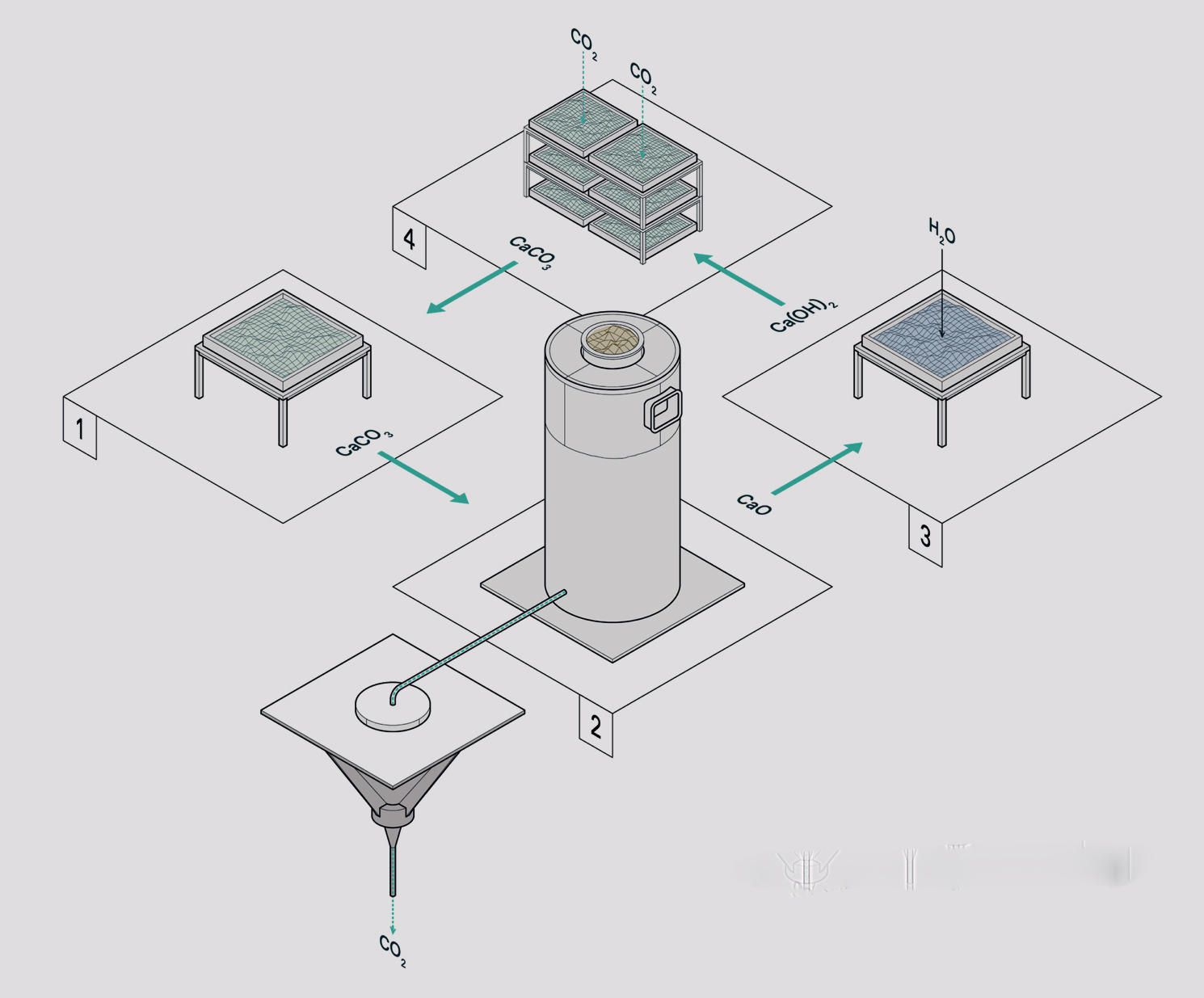

HEIRLOOM CARBON TECHNOLOGY CYCLIC PROCESS

The Heirloom process entails chemical phases similar to those in lime or portland cement production: Limestone is broken down into calcium oxide rock and CO2 gas using heat from a renewable-energy powered, electric kiln. The calcium-based material is spread onto vertically stacked trays where it acts like a sponge, pulling CO2 from the air before it is returned to the kiln and the process begins again. The captured CO2 gas is then permanently and safely stored underground or, when used in the CarbonCure process, embedded in concrete.

The DAC method has garnered the attention of carbon management-minded parties no less than Microsoft, which in September enlisted Heirloom to deliver 315,000 metric tons of CO2 removal—one of the largest such contracts to date. That award followed Heirloom’s Notification of Selection from the U.S. Department of Energy (DOE) for a proposal tied to the Infrastructure Investment & Jobs Act’s Regional DAC Hubs program in Louisiana. Separately, Heirloom and CarbonCure await DOE word on participation in a DAC Hub project in Illinois.

Related article

Central Concrete, CarbonCure loop Heirloom-captured, atmospheric CO2