Sources: Charles Pankow Foundation, Haymarket, Va.; CP staff

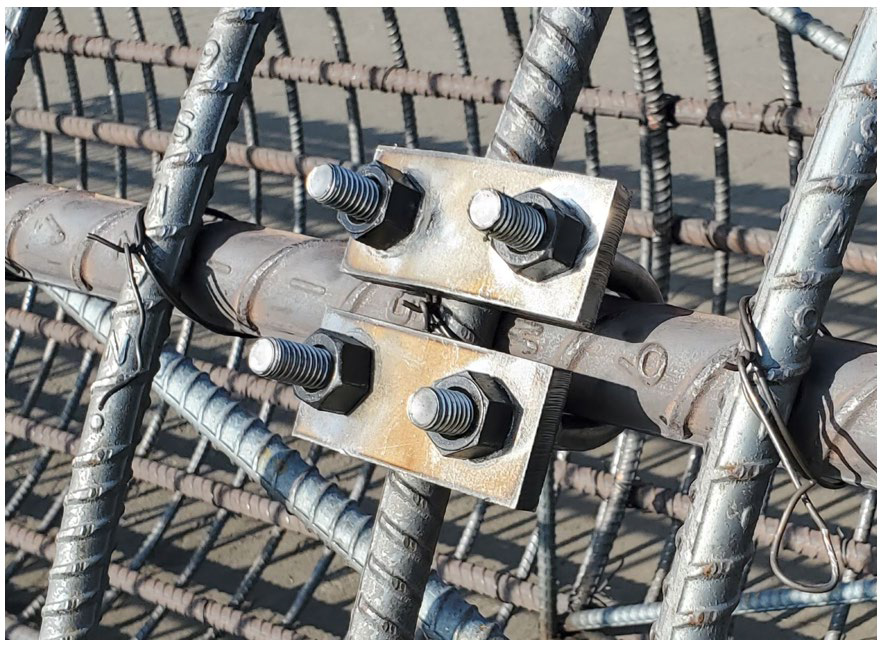

An investigation geared to identifying fabrication and assembly practices curtailing rebar cage collapse or failure incidents confirms the potential of U-bolt hardware to replace tie wires commonly used in lateral and transverse bar connections and increase cages’ lateral strength. The Pankow Foundation teamed with the American Society of Civil Engineers Construction Institute, University of Nevada, Reno and a host of heavy/civil construction interests to prove the U-bolts’ efficacy in tests and engineering analyses. They have released their findings and perspectives in Application of U-bolt Connector for Improving the Safety of Rebar Cages, posted here, and Guidelines for Circular Rebar Cage Assembly with U-bolt Connectors, posted here.

Along with reviewing analytical models, Nevada-Reno Department of Civil & Environmental Engineering investigators measured U-bolt connections’ mechanical behavior through experiments determining force-deformation response behavior in different degrees of freedom and for different rebar conditions. Data obtained from a previous study on a full-scale tie-wired rebar cage was used to develop and calibrate a nonlinear finite element model of the test specimen. The force-deformation response of U-bolt connections was then included in the model, replacing the tie wires, to investigate the effect of mechanical connectors on the lateral stiffness and strength of the rebar cage.

Joining Pankow Foundation and the ASCE Construction Institute in research funding were Association of Drilled Shaft Contractors, Association of Foundation Drilling, Concrete Reinforcing Steel Institute, Harris Rebar/Nucor, Keller Companies, Kiewit Corp., Parsons Corp., P.J.’s Rebar, Siefert Associates LLC, and Williams Form Engineering.