The Lynx Screed is a versatile alternative to completing concrete flatwork, consisting of a series of linkable pipes to accommodate slabs from 3- to 24-ft. widths. Unlike traditional roller screeds, the Lynx modular system removes the need for purchasing dedicated pipe lengths to offer easy adaptability for a multitude of pours. Its lightweight aluminum design decreases strenuous setup, shipping costs and transportation requirements for jobs that call for longer pipes.

“Screed adaptability and efficiency have been two of the biggest obstacles for concrete contractor productivity,” says Curb Roller Sales Manager Seth Ulmer. “With our Lynx Screed, contractors can work on pours ranging from a street to a sidewalk in the same day with just a few sections of pipe that can fit in a standard pickup.”

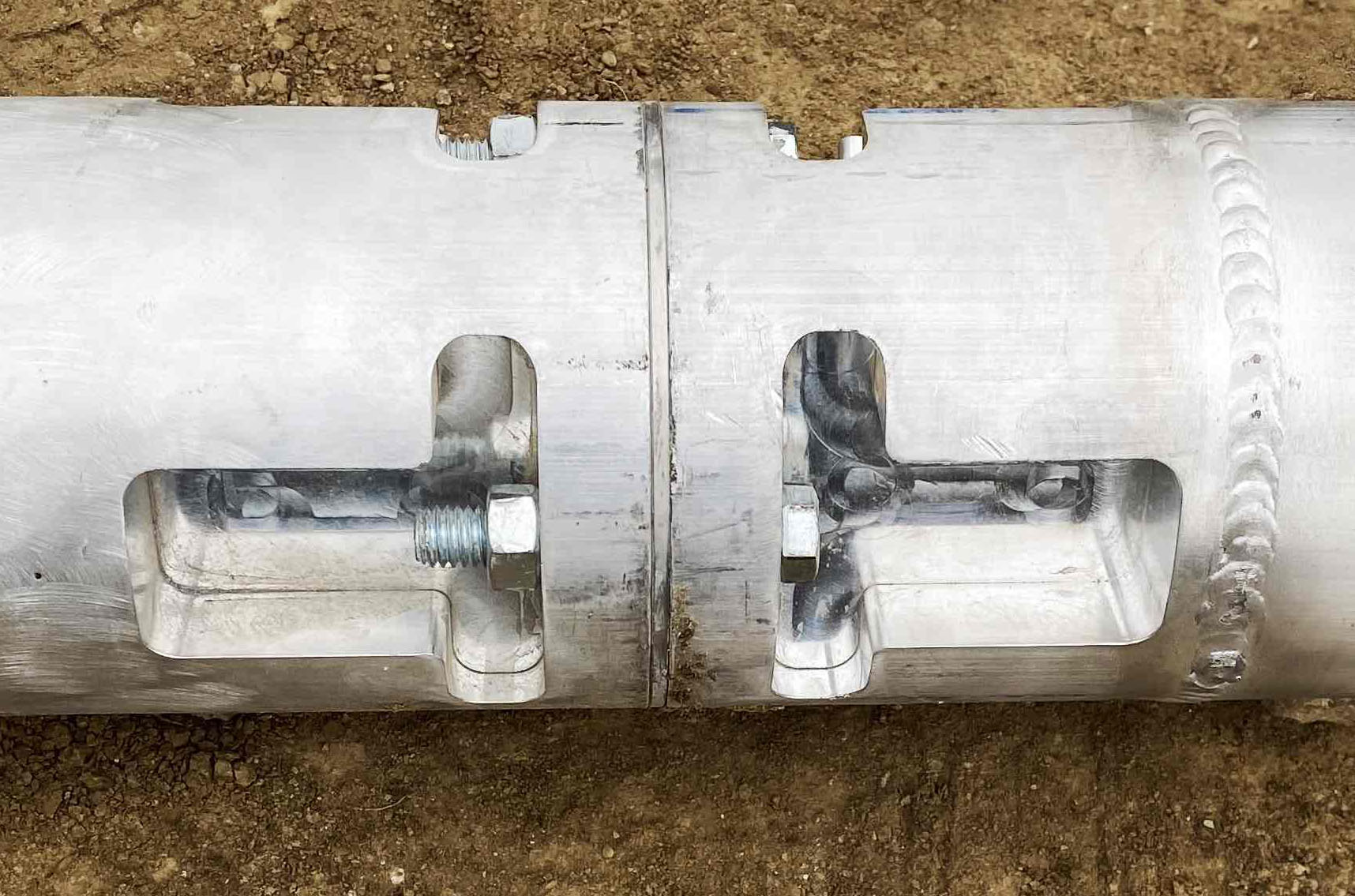

Compatible with the manufacturer’s Eel and Batt screeds, the Lynx modular system offers six pipe lengths that range from 3 feet to 9 feet. Package options are available, and the system can be customized to include pipe combinations that total up to 22 feet in length. The Lynx pipes are easily aligned and connected with three separate bolts and a centering ring. The operator simply places the centering ring between two pipes, securely seating them together. From there, the cutouts at the pipes’ ends allow the operator to easily insert three bolts, securing the pipes together by tightening the nuts. With this setup, users don’t have to retighten their pipes mid-job or worry about unthreading when changing screeding directions.

“Until recently, those looking for flexibility were stuck with cumbersome A-frame screeds or expandable roller screeds that require constant retightening or special tools,” Ulmer concludes. “With our stable connection points, customers can quickly assemble and complete the job. No hassle, no holdups.” — Curb Roller Manufacturing, Fairview, Kan., 785/467-3132; www.curbroller.com