safely at ground level.

New kits allow direct replacement of silo top elbows and piping/tubing subject to abrasive wear, with all preparation done safely at ground level. Each contains all components required to replace failing elbows, including two Smart Elbow deflection pieces plus all necessary piping/tubing, connectors and gaskets. The kits can be assembled on the plant floor prior to silo top installation, reducing personnel hazards associated with maintenance at high elevations.

Silo top sweep elbows are prone to failure due to large volumes of conveyed material impacting the elbow wall at high speed to change direction, causing abrasive materials to wear through the wall, followed by blow-outs and lost production due to downtime. The Smart Elbow design features a spherical chamber that protrudes partially beyond the 90 degree flow path. It prompts a loose ball of airborne material to rotate in the same direction as the airstream that powers it, while gently deflecting incoming material around the bend without impacting the elbow wall.

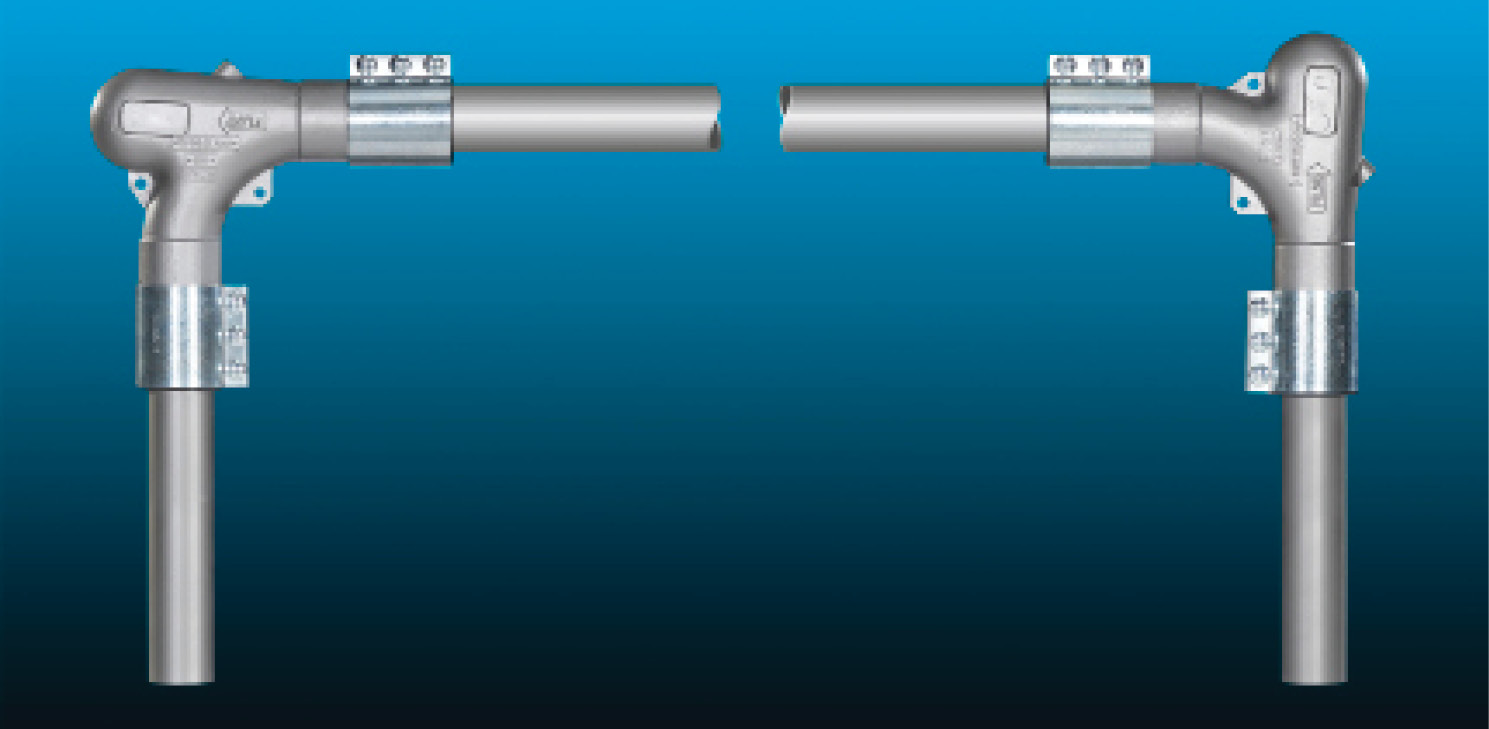

Socket style no-weld kits for all popular pipe and tube diameters include: two HammerTek elbows; one horizontal pipe or tube section; two vertical pipe or tube sections; and, four sleeve couplings with reducer gaskets.

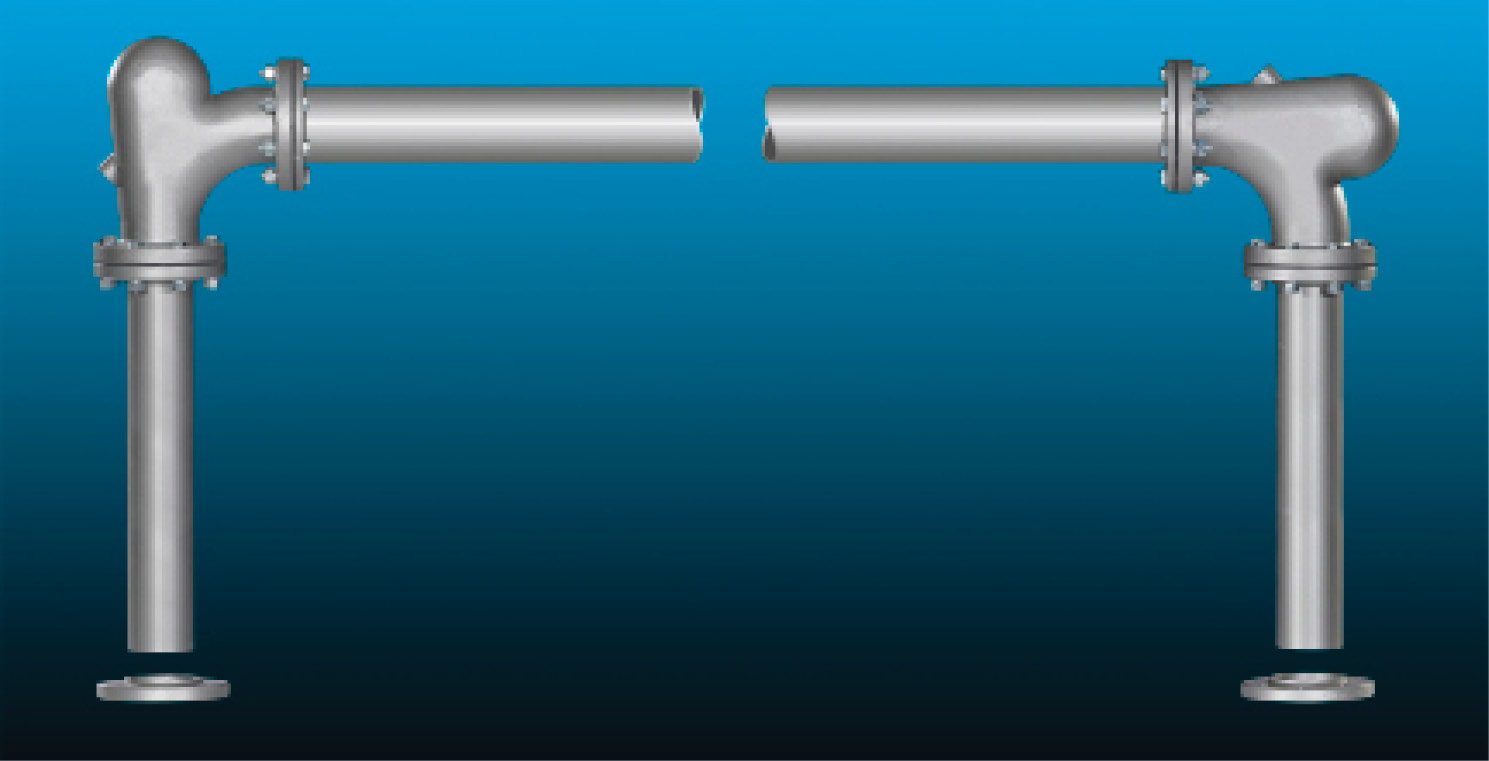

Flanged style kits for all popular pipe and tube diameters include: two ANSI flanged HammerTek elbows; one horizontal pipe or tube section with one welded ANSI flange; two vertical pipe or tube sections each with one welded ANSI flange; three loose ANSI flanges (for welding safely at ground level); and, four gaskets.

In addition to preventing elbow wear and failure, the design reportedly precludes friable materials from degrading and dusting, plastics from melting and forming streamers, and heat-sensitive materials from building up and plugging, while reducing pressure drop and offload times by up to 50 percent. — HammerTek Corp., Bethlehem, Pa., 610/814-2273; www.hammertek.com

two Smart Elbow defl ection elbows, one horizontal pipe or tube section, two vertical pipe or

tube sections, three loose ANSI fl anges that can be welded at ground level, and four gaskets.

two Smart Elbow defl ection elbows, one horizontal pipe or tube section, two vertical pipe or

tube sections, three loose ANSI fl anges that can be welded at ground level, and four gaskets.