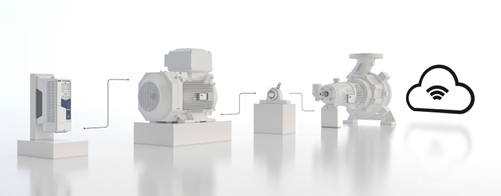

A new service is enabling industrial operators to maximize energy efficiency and boost sustainability by identifying motor-driven equipment in their facilities with the best energy-saving potential. The ABB Ability Digital Powertrain Energy Appraisal service draws on data measured from fleets of digitally connected electric motors and variable frequency drives to show where and how much energy can be saved by upgrading to the latest high-efficiency technologies. Operators can then make data-driven decisions when prioritizing investments.

Upgrading to energy efficient technology is one of the simplest and most cost-effective ways to lower energy consumption and associated greenhouse gas emissions, ABB officials note. Across the world’s 300 million industrial motor-driven systems, they add, there is potential to reduce global electricity demand up to 10 percent by switching to high-efficiency systems.

“The challenge for an industrial operator is knowing where to start in a fleet of electrical motors,” says ABB Motion Services Adrian Guggisberg. “We developed the new Digital Powertrain Energy Appraisal service to provide clarity by analyzing motor data and identifying where businesses should focus investment to maximize energy efficiency gains that reduce operating costs and carbon dioxide emissions.”

One operator reaping the benefits is Waggeryd Cell, a pulp mill in southern Sweden with industry-leading energy efficiency. In an effort to further improve the efficiency of its energy-intensive process, the mill is building its ABB Ability Condition Monitoring system. It draws data from digitally connected motors in refiners, process pumps, fans and conveyor belts. Under the new Digital Powertrain Energy Appraisal service, ABB’s experts use data from the same sources to identify the 10 motors with the most potential for improving energy efficiency. Waggeryd has now prioritized replacement of six of these motors to reduce energy consumption and attendant greenhouse gas emissions.

A traditional energy efficiency appraisal requires time-consuming manual data collection and evaluation and covers only the largest motor-driven systems as they are typically seen as having the most potential for saving energy. This tendency could overlook significant energy-saving opportunities for electric powertrains that are smaller, less accessible or where energy-saving potential is not obvious. The new ABB digital appraisal service uses a plug and play approach to simplify energy efficiency assessments by pulling operational data remotely from across an entire fleet of digitally connected motors. This approach provides deeper insight into the business case and carbon footprint benefits of upgrading to high-efficiency motordriven systems. — ABB Motion Services, www.go.abb.com/motion