The CSS-CUCF44F carbon FRP fabric—the heaviest code-listed grade—has joined company’s Composite Strengthening Systems for concrete or masonry structures. Upgraded with new, flat-weave fiber technology, the 44-oz. fabric now saturates as easily and quickly as lighter fabrics, significantly reducing installation time.

Fiber-reinforced polymer systems, engineers note, are created by combining carbon fabrics with a polymer material and commonly used in concrete repair and restoration projects as a lightweight, high-strength reinforcement. Strength and performance features have made FRP systems increasingly popular in construction and retrofit applications involving aging, damaged, or overloaded concrete structures. The CSS-CUCF44F affords a solution requiring fewer fabric layers for reduced labor costs, consistent quality control, and more successful inspection rates.

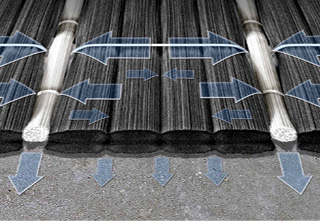

“Since fewer layers of fabric translates to fewer potential issues in the field, the new CUCF44F provides engineers and installers a solution to achieve design strengths without worrying about saturation issues that prevent fabrics from directly transferring to substrates,” says Simpson Strong-Tie Product Manager Aniket Borwankar. After testing several designs, he adds, the company opted for a flat-weave technology that incorporates a fiberglass cord in the FRP fabric to allow saturant to flow around fabric bundles, improving the overall saturant absorption. — Simpson Strong-Tie, Pleasanton, Calif., www.strongtie.com/css