Ready-mix producers of all sizes are leveraging cloud computing and mobile technology to meet the challenges of the current marketplace and ramp up their competitiveness.

by Victoria K. Sicaras

Traditionally, only large ready-mix producers had the resources to corner the market on larger jobs, such as high-rises and highway projects. While smaller, local operations could offer a more personal touch, they were often priced out of the technology and infrastructure needed to optimize operations and compete for large, complex jobs. Without such tools, their service costs were often higher and their basic processes took longer.

Now more than ever, smaller concrete producers are realizing the value of using cloud-based and mobile technology to expand capabilities so they can win more work. Cloud computing enables software and tech solutions to be sold either as monthly services or per user, eliminating the need for companies to pay large, upfront costs for system and equipment installation. Consequently, small producers can more readily afford the technology required to offer seamless billing, mobile quality control services and a wider area of coverage with remote-access plant controls. They can keep up with the speed of business at relatively low costs and streamline processes to accomplish more without adding staff.

“Our ability to do more with less has basically been driven by advancements in technology,” says Dave LaPointe, president of Point Ready Mix in McHenry, Ill. “A strong network structure, a GPS truck tracking system and the ability to deliver real-time information to mobile devices keeps us productive and efficient.”

Plus, “For a small producer, being able to offer a mobile app to customers that provides transparency into their orders is pretty cool. It helps us provide the best customer service experience,” says Daniel Bugbee, president of Garrott Bros. Ready Mix, based in Gallatin, Tenn.

LAYING THE GROUNDWORK: AFFORDABLE INFRASTRUCTURE CONNECTIVITY

Ten years ago, Tony Thier, president of BARD Materials in Dubuque, Iowa, would have named “connectivity” as the biggest challenge small producers faced, especially those in rural areas. The connectivity options for truck tracking, dispatch and cameras were not adequate in terms of reliability and bandwidth.

“If you’re a small company, the price tag for installing a dedicated connection to a small plant was expensive—and mobile data coverage was spotty in rural areas,” he notes. “Larger plants with higher volume could afford a dedicated connection, and urban areas naturally had better mobile coverage.”

Rapid advancements in cellular networks and broadband connectivity in small towns have been game changers for small producers in recent years, Thier notes, making high-speed Internet and wireless connectivity what it is today: accessible and affordable.

“That connectivity continues to improve, with some electric companies running fiber on powerlines and companies that provide satellite options like SpaceX’s Starlink,” he adds.

MOBILE TECHNOLOGY: THE GREAT EQUALIZER

“Once small producers have access to high-speed Internet and connectivity, cloud- and web-based systems become the great equalizer,” observes Thier.

Traditional software solutions that are typically purchased and installed on premises, like dispatch systems, often come with a flat rate per plant, regardless of the plant size. Today’s cloud- and web-based solutions are hosted by providers who charge by the transaction or number of users, which Thier says brings the cost down significantly for producers with smaller plants and fewer staff members.

“Companies of all sizes now have access to the same tech tools, and at an affordable price,” he affirms.

With the cost of cloud-based technology tools now within their budget, BARD Materials can take advantage of truck tracking tools and an integrated dispatch system that can be accessed via mobile app to deliver concrete loads with a high level of efficiency. The producer also performs remote batching and uses imaging systems to scan and electronically route documents, thus reducing paper waste.

SCALING UP WITH DIGITAL TOOLS

With eight locations in northern Illinois and southern Wisconsin and 100 trucks delivering concrete, Dave LaPointe of Point Ready Mix says his company has the capacity to handle large commercial jobs and technical work, thanks in part to technology investments.

In 2017, Point Ready Mix moved from a plant-level dispatch model to a central dispatch center that makes orders visible to everyone. This allows team members to evenly balance dispatch workloads for each plant so they can provide higher levels of service. “We repurposed existing office space and restructured our network with all new hardware. We implemented the latest in phone technology and upscaled our digital connections to all plant locations and the main office,” LaPointe explains.

The producer also uses the cloud-based Digital Fleet GPS truck tracking system. Through in-vehicle tablets equipped with voice-to-text features, drivers can easily communicate with dispatch, access real-time load ticket information and receive turn-by-turn directions, all of which leads to more accurate delivery times. Dispatchers are always aware of a mixer’s location and performance, and they can route trucks accordingly.

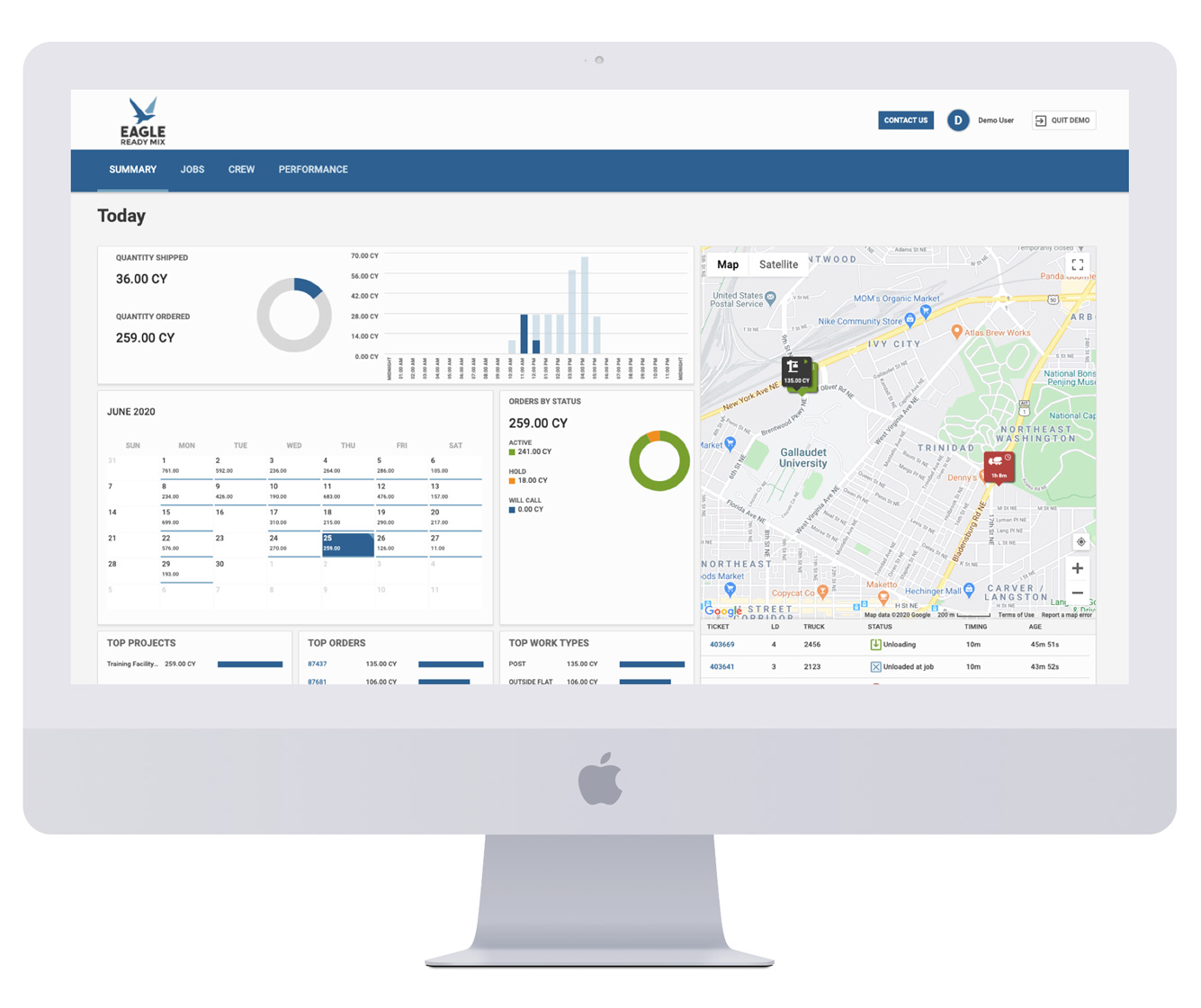

Additionally, Point Ready Mix also was first in their market to introduce a mobile app for customer service. The Material Now app from BCMI (Bulk Construction Materials Initiative) taps into the dispatch system to provide ready-mix customers with real-time access to order statuses and trucks en route to the job as well as crew performance and historical data. “No time is wasted submitting a request or making a phone call,” says LaPointe.

“The app has proven to be especially helpful to our customers who have foremen overseeing crews in multiple areas,” he adds. “Foremen can use their mobile devices to drill into the activity of single pours for a status update.”

On the operations side, the company uses BCMI’s Material Pro app for real-time access to production and delivery information. Efficiency measures, raw material needs, batch weights, batch accuracy and the status of orders are all readily available to internal team members. With the app, sales staff can monitor the progress of multiple jobs from anywhere on their mobile devices. Operations staff can identify upcoming needs for assets or materials. The company recently issued tablets to team members so they can use Material Pro to easily work outside of the office.

The mobile apps also make it easy to integrate data across systems and quickly gather information for customers and quality control. LaPointe says his staff has more timely information on financials, demand for raw materials and trends to analyze—which proved to be highly beneficial for forecasting during the coronavirus pandemic when supply chains became strained.

“We don’t just have access to data, we have the ability to index data from multiple systems, pass data between systems and assemble data for delivery in a summarized, meaningful way that helps us manage the business,” says LaPointe.

TECHNOLOGY FOR SOCIAL DISTANCING

Two and a half years ago, Tennessee’s Garrott Bros. Ready Mix introduced a mobile delivery ticket platform. Shortly after that, the producer offered the Material Now app to customers. “Our goal is to leverage technology to give customers the information they want—and make sure they have all the data they need at their fingertips,” says Daniel Bugbee, president.

Beginning March 2020, the producer’s use of electronic tickets paid off in a big way, he adds: “While there were challenges early on getting customers to understand the direction we were going, when Covid-19 hit this year we didn’t miss a beat. It was the best technology we had in place for the pandemic, and we continue to receive positive feedback about it.”

Electronic ticketing enables drivers and customers to remain safely distanced so work can proceed as usual. With just a few swipes of a finger on their own devices, customers can receive the paperless tickets and sign for deliveries, making the concrete delivery process contactless.

Bugbee says the company also benefited from having a mobile app available for customers to look up their order information and review their accounts 24/7. “Customers can answer their own questions, such as ‘Where’s my truck,’ which reduces calls to dispatch. They can even set up alerts to notify them when their concrete is on its way. We’ve also seen some finishers use the app to determine how their crews’ pouring cycles went.”

THE LEVELING EFFECT

Small producers who are taking advantage of cloud-based tools—such as mobile dispatch and truck monitoring systems (versus a room full of dispatchers) and cloud-based data storage (no need for a server room)—are finding they can offer the services and service levels that formerly tied customers to larger producers. As a result, they are winning more bids.

“So much has changed during the 25 years I’ve been in the business,” says Point Ready Mix’s Dave LaPointe. “Service levels, capacity, accuracy and efficiencies have all greatly improved due to the advancement of dispatch software. Ready mix trucks have also become much ‘smarter’ over the years, with GPS truck tracking solutions making it possible to give our customers transparent access to their trucks on a map in our mobile app.”

Daniel Bugbee says technology plays a big role at Garrott Bros. Most, if not all, of their field operations and sales force start their day with BCMI’s Material Pro app. “It is a great tool to get a snapshot of our performance as a company—being able to have KPIs [key performance indicators] set up on first-round orders is a great gauge to our service. The app also allows them to identify customers they need to contact without calling the dispatch office,” he notes.

BARD Materials’ Tony Thier looks forward to implementing future technologies to optimize logistic decisions, reduce the variability of the concrete and improve safety. However, he is most excited about tech tools’ capacity for expanding human potential and well-being. “These technologies will facilitate the mundane tasks, reduce safety risks and make multivariable decisions so individuals can focus on developing and utilizing their most human skills. Skills that build relationships and solve problems creatively to make more positive impacts on our communities and our country.”

Because producers are able to expand their services without ramping up in size, they remain small enough to provide a personal touch and nimble enough to quickly deliver solutions.

“Our industry is largely relationship-based. Our size allows us to stay in tune with customers and service levels so we can identify needs and continue pleasing our customers,” says LaPointe.

“The challenge lies in making sure the customer knows that just because we are not in three to five states, we still value their relationship and business and we can get problems resolved promptly,” adds Bugbee.

To learn more about how technology plays unique roles for producers who serve small markets, see this month’s Technology Trends column.

Vikki Sicaras is a freelance writer based in Countryside, Ill. She has more than 15 years of experience working as a writer and editor serving the construction industry.

HOW TO BECOME A TECH-SAVVY CONCRETE PRODUCER

Today’s concrete producers have at their fingertips the tools to monitor operations and costs so they can better support customers and increase their bottom line. The following are examples of how Smith Ready Mix in Valparaiso, Ind., uses cloud-based, integrated software solutions to provide greater visibility into day-to-day activities.

“I don’t know what we ever did without these tools,” says President Doug Smith. “Once you have all the data at your fingertips, you can’t go back.”

Enterprise resource planning (ERP). When all platforms used by a company are centered around and feed into an ERP, that ERP platform then acts as a central repository for all company data, including accounting, purchasing, billing, sales and maintenance. The integrated platform makes it simple to collect and report data and make more immediate business decisions.

Dispatch. A cloud-based ready-mix dispatch system that can be accessed via mobile app can provide up-to-the-minute access to fleet statuses, plant volumes, customer accounts, quotes, and project history. Team members can log in from anywhere, anytime, to find the information they need. Customers can use the mobile app to track orders in real time.

Truck tracking. Equipping trucks with global positioning systems (GPS) and telematics solutions gives producers more timely information about their assets’ whereabouts, enabling dispatchers to track trucks and their stage in the delivery cycle without having to depend on updates from drivers.

Quality control. Mix management tools allow QC managers to view and change concrete mixes. When specimen test results automatically feed into a dispatch system, records are immediately available to QC managers. There are no additional wait times for data entry or extra communication. When the dispatch system can be accessed via mobile app, QC personnel at jobsites can access previous test results, update a customer or take any other necessary action.

Silo readers. Adding sensors to silos gives producers more accurate information about material availability. This eliminates the need to call different plant locations asking personnel to manually check volumes. Using sensors to measure and transmit information also reduces the need for manual data entry, which decreases the likelihood of human error.

Drones (inventory). Instead of physically checking piles of material, producers can take photos with drones and upload them to cloud-based inventory software to reconcile inventories more accurately.