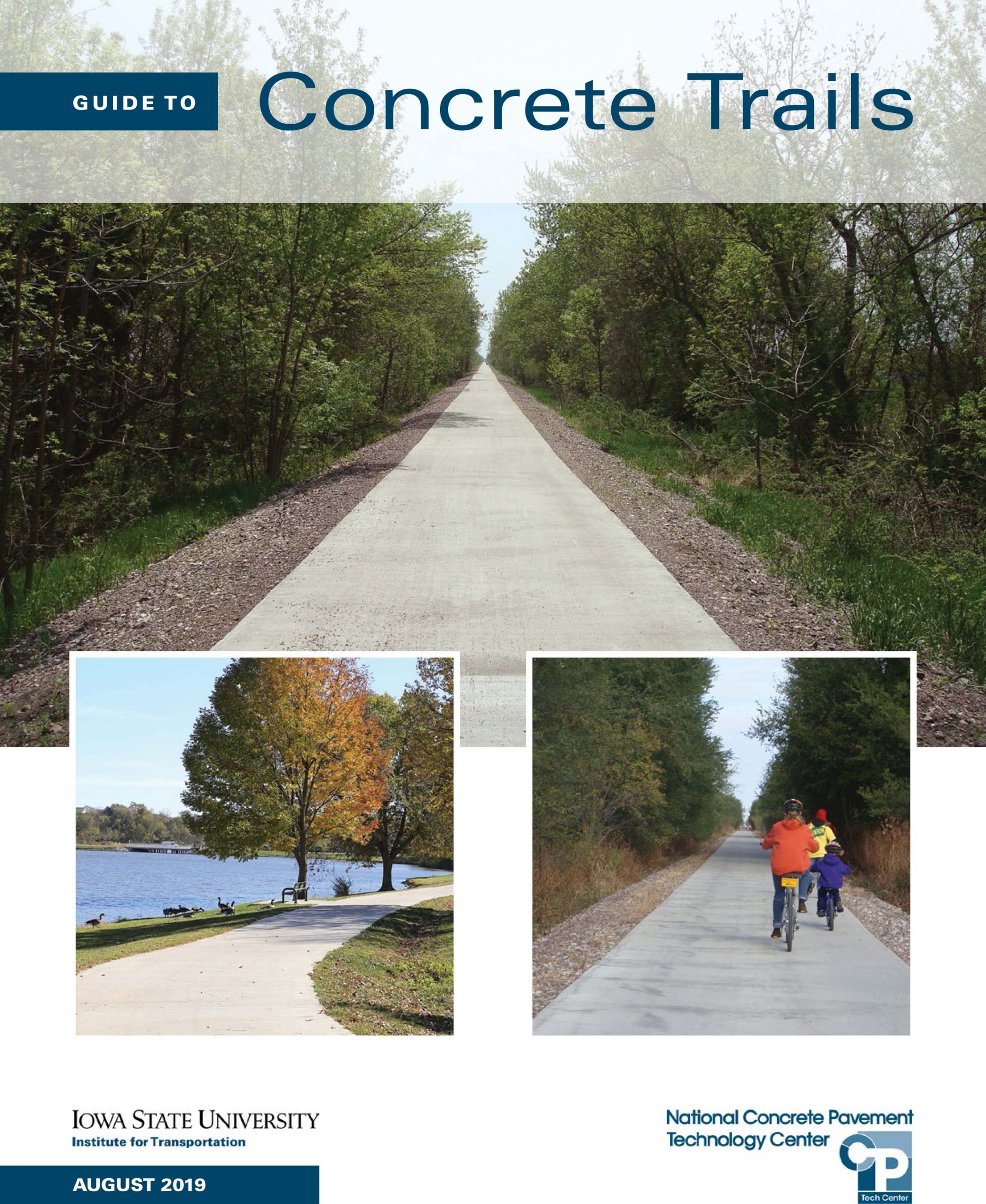

Looking beyond roads, streets, parking lots and traditional flatwork, the Ready Mixed Concrete Research and Education Foundation responds to an emerging pavement market opportunity for ready mixed concrete producers in its latest publication. The 36-page Guide to Concrete Trails covers project background and funding; choice of concrete versus alternative paving materials; design and engineering; concrete mix designs, delivery and placement; paving machinery and slab finishing methods; plus, jointing, curing and maintenance.

Read MoreMonth: September 2019

Glen-Gery secures North American territory from Italy’s premier brickmaker

Wyomissing, Pa.-based Brickworks North America Corp., parent of Glen-Gery Corp., has purchased the licensing rights to sell San Selmo brick products across North America. The distinguished, high-style brick is produced in Italy by S. Anselmo Group, a fifth-generation boutique maker of luxury units, and joins Glen-Gery’s International Collection. S. Anselmo craftsmen have been conceiving, designing and creating unique brick designs since 1903, securing orders for many high profile restoration projects in Europe, plus high-end residential or architectural landmark jobs this side of the Atlantic.

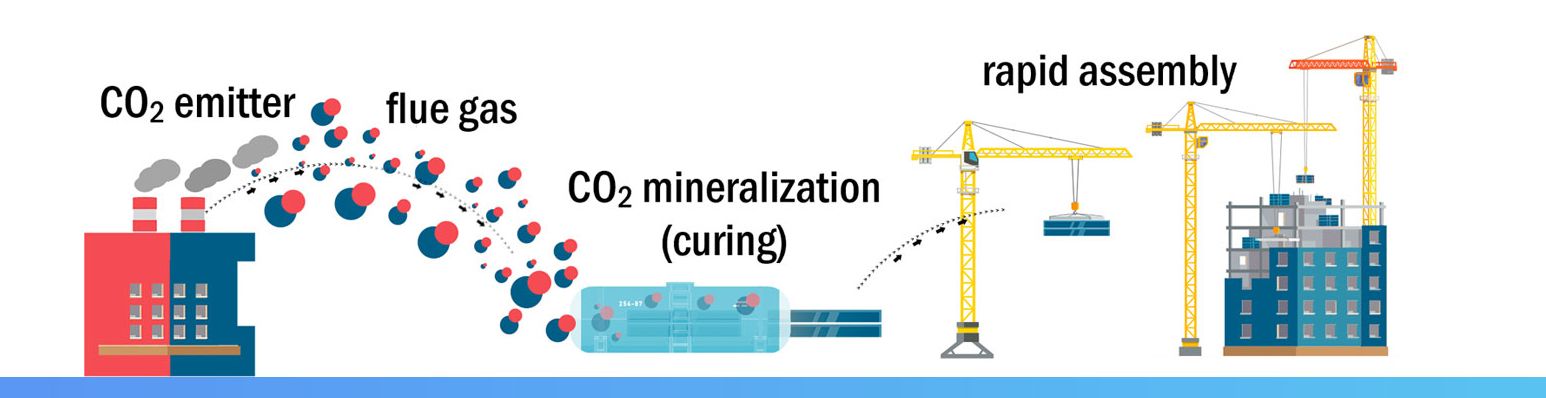

Read MoreUCLA team demonstrates carbon dioxide recycling in precast production

A University of California, Los Angeles team in the final round of the $20 million NRG Cosia Carbon Xprize competition has scheduled a February 2020 demonstration of a process yielding concrete blocks or elements through capture of carbon dioxide gas in coal-fired power generation. Carbon Upcycling UCLA will stage the 30-day undertaking at the Dry Fork Station near Gillette, Wyo.; members see daily production of up to 10 tons of their CO2ncrete-trademarked units for use in wall construction.

Read MoreEP Henry, Lafarge, Solidia mark low-carbon binder’s commercial launch

A venture between the LafargeHolcim U.S. Cement business and Solidia Technologies will supply EP Henry’s Wrightstown, N.J., block & paver plant with a reduced carbon dioxide binder plus companion curing equipment. The proprietary production method’s formal launch stems from a six-year effort by the three companies to bring to commercial scale a technology that reduces embodied CO2 in manufactured concrete by up to 70 percent versus conventional, portland cement-based production methods. Development has centered on Solidia Cement milled at the Lafarge Whitehall plant in western Pennsylvania, along with aggregate materials Solidia Technologies sources separately.

Read MoreOldcastle APG shores up Pacific NW footprint with Abbotsford Concrete

The acquisition of British Columbia-based Abbotsford Concrete Products will expand Atlanta-based Oldcastle APG’s hardscape unit offerings and manufacturing capabilities in its western Canada region. Founded in 1989 by Clifford Leach, Abbotsford Concrete has established itself as a hardscapes leader under the direction of sons Chris and Bob Leach. The producer has strong dealer relationships, exceptional quality assurance, innovative engineering, and a proven operational focus, Oldcastle APG affirms. In addition to a market-leading hardscapes brand, the deal brings two top tier paver, slab and segmental retaining wall production facilities.

Read MoreConcrete pipe: Unquestionably best for drainage construction

The American Concrete Pipe Association’s new video, linked to YouTube from www.concretepipe.org, presents precast, rigid concrete pipe as the ideal choice for durable drainage installations. In every region across North America, engineers, the association contends, transportation departments and contractors know they can trust concrete pipe as the most resilient choice to last for over 100 years. The video explores benefits and performance characteristics backing up that confidence:

Read MoreSika, celebrity architect BIG team on 3D printing demonstration

The parent of Sika Corp. is partnering with one of the world’s top architects, Bjarke Ingels Group (BIG), to showcase 3D concrete printing capabilities at the “Formgiving” Exhibition at the Danish Architecture Center in Copenhagen, Denmark. Running through January 2020 in the architect’s home base, the exhibition focuses on the future of construction and how it shapes the planet.

Read MoreCorps, Marines team cites 3D concrete printing first in high volume demo

Marine Corps Systems Command and 7th Engineer Support Battalion staff joined U.S. Army Corps of Engineers Construction Engineering Research Laboratory (CERL) colleagues last month to test a 3D concrete printing operation with a late model volumetric mixer feeding a 3-in. nozzle. The Champaign, Ill., demonstration was staged to fabricate a field-grade bunker, and followed Marine Corps units’ barrack and bridge structure printing with a 2-in. nozzle assembly.

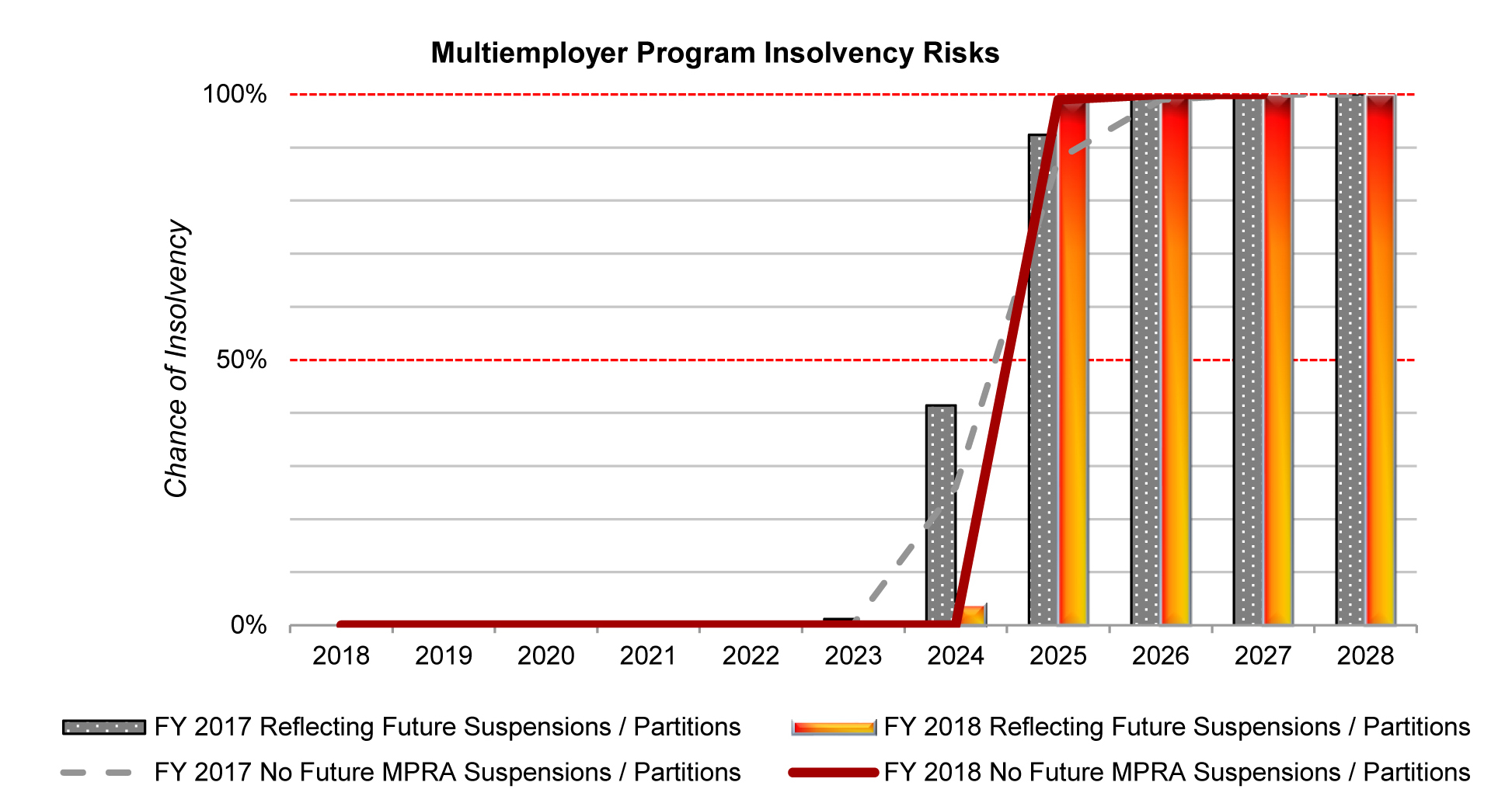

Read MoreMultiemployer pension backstop plan advances on Capitol Hill

From the Associated Builders & Contractors, Washington, D.C. … The U.S. House of Representatives has passed the Rehabilitation for Multiemployer Pensions Act (H.R. 397), with 29 Republicans joining the majority in a 264-169 vote. Advocates argue the measure is needed to protect the pensions of 1.3 million workers in certain multiemployer pension plans (MEPP)—up to half of which cover construction trades participants—and prevent a Pension Benefit Guaranty Corporation (PBGC) collapse.

Read MoreTax reform a principal catalyst behind $100M precast plant venture

Fortified Precast Technologies, LLC has outlined an ambitious Florida residential real estate development plan, leveraging a partnership with German precast concrete production specialist Vollert Group and Opportunity Zone provisions in the Tax Cuts & Jobs Act of 2017 (TCJA). The company’s Fortified Precast Opportunity Fund is authorized to raise $100 million in $20 million increments to build five plants incorporating Vollert mix delivery, form pallet and companion robotics or casting components. At 32,720 sq. ft. of daily wall panel output, each operation would be capable of supplying more than 4,200 home projects annually. The capacity would be initially targeted to the Sunshine State market, which has seen residential building permits climb from 116,200 in 2016, to 122,700 in 2017 and 142,300 last year.

Read More