A University of California, Los Angeles team in the final round of the $20 million NRG Cosia Carbon Xprize competition has scheduled a February 2020 demonstration of a process yielding concrete blocks or elements through capture of carbon dioxide gas in coal-fired power generation. Carbon Upcycling UCLA will stage the 30-day undertaking at the Dry Fork Station near Gillette, Wyo.; members see daily production of up to 10 tons of their CO2ncrete-trademarked units for use in wall construction.

|

|

|

| Carbon Upcycling UCLA has cast sample blocks and regular specimens in CO2ncrete process development. The team sees technology licensing prospects where emissions-intensive businesses enter or host precast concrete production. |

The team has proved a prototype system for incorporating power plant CO2 emissions into concrete mixes, and is finalizing design of the Dry Fork Station equipment. “Our vision is that CO2ncrete will be at the center of a more sustainable and environmentally responsible construction ecosystem,” says Professor of Civil and Environmental Engineering Gaurav Sant, team lead and UCLA Institute for Carbon Management director. “We think we have a revolutionary process and product. Not just because of our carbon utilization technology, but our end product appeals to both energy and building construction companies to enable them to meaningfully reduce carbon dioxide emissions.”

The carbon-to-concrete technology throws a one-two punch at CO2 emissions, he adds, as it a) captures the greenhouse gas before it exits the power plant, reducing releases to the atmosphere; and, b) cuts down on the use of portland cement, the product of carbon- and energy-intensive processes. CO2ncrete block or elements will reportedly have a carbon footprint at least 50 percent below that of equivalent products cast from conventional concrete mixes.

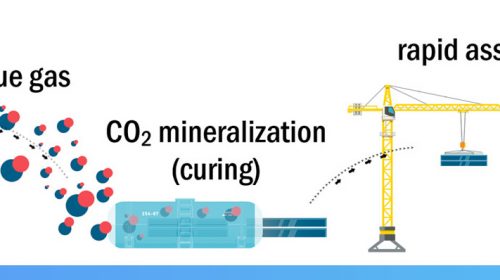

Carbon Upcycling’s process locks flue gas CO2 into limestone within the finished concrete. It requires minimal capital expenditure due to adaptability to host facilities and absence of gas capture systems, and can incorporate low-value fly ashes, including those stored in landfills and ponds, while providing engineering performance equivalent to conventional concrete.

Carbon Upcycling UCLA is one of 10 teams in the NRG Cosia Carbon Xprize finals, split evenly between coal and natural gas tracks and aimed at demonstrating the most viable technologies for turning CO2 emissions into commercial products. The winning team in each track will be awarded $7.5 million toward commercialization of its concept. Carbon Upcycling UCLA received a $1.9 million grant from the U.S. Department of Energy in 2018, and a $1.5 million gift the prior year from the Anthony and Jeanne Pritzker Family Foundation. Along with each of the other nine finalists, the team also received $500,000 from the Xprize Foundation, based in Culver City, Calif.

Carbon Upcycling stands to license its technology to emissions-intensive sectors. Licensees can potentially monetize carbon reductions by securing credits in eligible carbon markets; address regulatory and corporate social responsibility factors compelling emissions reduction strategies; and, market CO2-based concrete formulations as low-carbon alternatives to conventional construction.