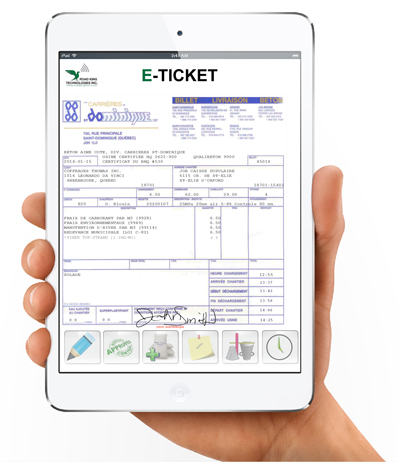

Cloud-based information technology developer has added E-Ticket to mixer fleet-suited management and GPS tracking systems. The program, Road King Technologies officials note, replaces paper delivery tickets; saves an average of three to five minutes of driver’s time; automatically logs site arrival plus mix discharge start and completion times; and, captures signatures on pdf documents, automatically forwarded to designated e-mail accounts.

Read MoreDay: March 17, 2014

Onboard or plant-based equipment automates slump, mix adjustments

Quebec-based SensoCrete has developed plant and onboard equipment solutions to automate water and admixture additions to ready mixed concrete loads following trucks’ departure from charging alleys. Anchoring the technology is the Concrete Optimizer, which SensoCrete developers call “drivers’ personal assistant,” as it measures mix slump, recommends adjustments to align mix properties with specifications, and controls liquid additions to the load. A drum-mounted gauge relays mix slump, volume, and uniformity readings to an onboard computer, along with drum revolution count. The screen shows drivers measured versus targeted mix properties, slump tracked within ½-in. accuracy.

Read MoreDelaware Valley deploys Pennsylvania’s first CNG-fueled mixer

Delaware Valley Concrete Co. (DVC) kicked off 2014 dispatching its premier compressed natural gas-powered mixer, an Oshkosh S-Series front discharge model converted from diesel as part of the manufacturer’s new glider program.

Based in Hatboro, Pa., northwest of Philadelphia, DVC is the first concrete company running a CNG mixer in Pennsylvania and Delaware. “As a fuel, CNG has plenty to offer. Not only is it cheaper to produce than diesel, it also burns much cleaner,” says DVC President Mario Diliberto. “We are reducing our carbon footprint in the industry and fueling costs as well.

Read MoreConcrete Industry Management Program auction grosses $800K+

With confirmed live, online and silent bids exceeding $810,000, the Concrete Industry Management Program National Steering Committee reports that the 2014 World of Concrete Auction bested last year’s record gross by nearly $200,000.

“We had a record in terms of the value of donated items and auction attendees that helped make this year’s event a huge success,” notes Cemex’s Mike Philipps, who chaired the committee organizing the Las Vegas Convention Center-staged, January 22 fundraiser. “Everyone stepped up to donate and bid on great items.”

Read MoreResidential market upturn fuels near-double digit gains for fiber cement

Demand in the U.S. for fiber cement products is forecast to rise 8.5 percent annually through 2017 to 2.9 billion square feet—valued at $2.2 billion—according to a new study from The Freedonia Group, Inc., a Cleveland-based industry market research firm. “Advances will be driven by a rebound in residential building construction spending, particularly in the new housing segment,” states Matt Zielenski, an analyst with The Freedonia Group. Growth will be further spurred by increasing use of fiber cement products because of their favorable aesthetic and performance properties. These and other trends are presented in Fiber Cement.

Read MoreSEFA OUTLINES MAJOR ASH PROCESSING INVESTMENT

Scheduled International Concrete Sustainability Conference speakers include Hank Keiper of the SEFA Group, who will present “The Future of Fly Ash is Under Our Feet,” during the May 12-14 event in Boston. He will discuss the dwindling availability of coal fly ash suitable for use as supplementary cementitious material in the U.S. due to environmental regulations and market factors. To ensure a future supply of high-quality, Class F fly ash, SEFA Group has modified its proprietary thermal beneficiation process to accept fly ash reclaimed from disposal sites, including both landfills and settling ponds. The adaptation of a proven technology will create a consistent supply of premium fly ash, prevent future disposal of material initially below ASTM C618 grade, and offer existing site

remediation solutions.

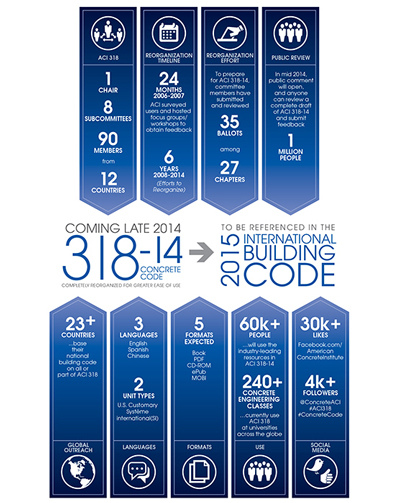

ACI Committee 318 reorganizes Building Code around designs’ structural members

American Concrete Institute is finalizing ACI 318-14: Building Code Requirements for Structural Concrete, announcing at World of Concrete 2014 the streamlined document’s new orientation to engineers; more intuitive flow of requirements compared to earlier versions; and, centralized construction requirements in a single chapter.

Read MoreBIG CITY MAYORS EMBRACE ENERGY EFFICIENT BUILDINGS

Recognizing resources consumed over buildings’ operating life cycles, mayors from 10 major U.S. cities will undertake an effort to significantly boost energy efficiency in new and existing facilities. Supporters contend such measures could cut as much climate change pollution as generated by 1 million to 1.5 million passenger vehicles every year, and lower annual energy costs by nearly $1 billion.

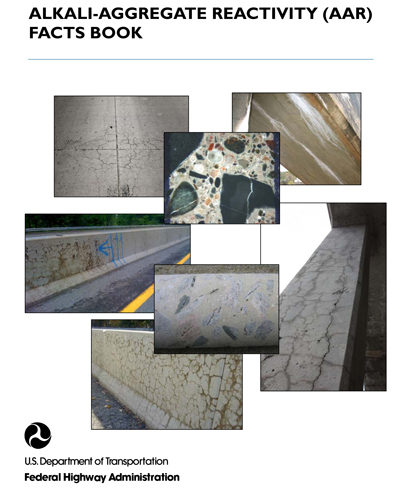

Read MoreFHWA PUBLISHES ALKALI-AGGREGATE REACTIVITY REFERENCE

From the Federal Highway Administration’s Focus newsletter… Alkali-aggregate reactivity (AAR) can occur in concrete structures and pavements as both alkali-silica reaction (ASR) and alkalicarbonate reaction (ACR). FHWA’s new Alkali-Aggregate Reactivity Facts Book (Pub. No. FHWA-HIF-13-019) discusses both types of reaction but concentrates on ASR, as cases of ACR are more limited.

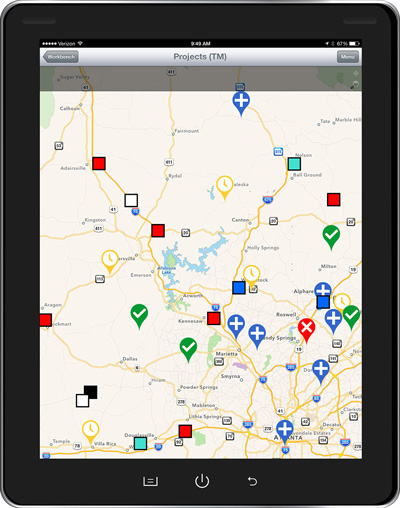

Read MoreLafarge, Lehigh and Vulcan sales teams lead adoption of new enterprise mobile apps

Sources: Catavolt Inc., Alpharetta, Ga.; CP staff

After initial deployments with four major integrated producers and a top precast/prestressed operator, Catavolt has unveiled technology supporting rapid, low-cost development of custom apps providing geographic market intelligence and perspective, plus customer relationship management program-grade data.

Read More