Daimler Trucks North America has begun a pilot program for plastic parts produced using 3D printing technologies, which the manufacturer sees as soon playing a significant role in heavy-duty fleet maintenance. More importantly, management notes, DTNA views 3D printing as an opportunity to better serve customers, particularly those needing parts that have been difficult to provide through traditional supply chains due to truck age or very low or intermittent demand.

Read MoreTag: Daimler

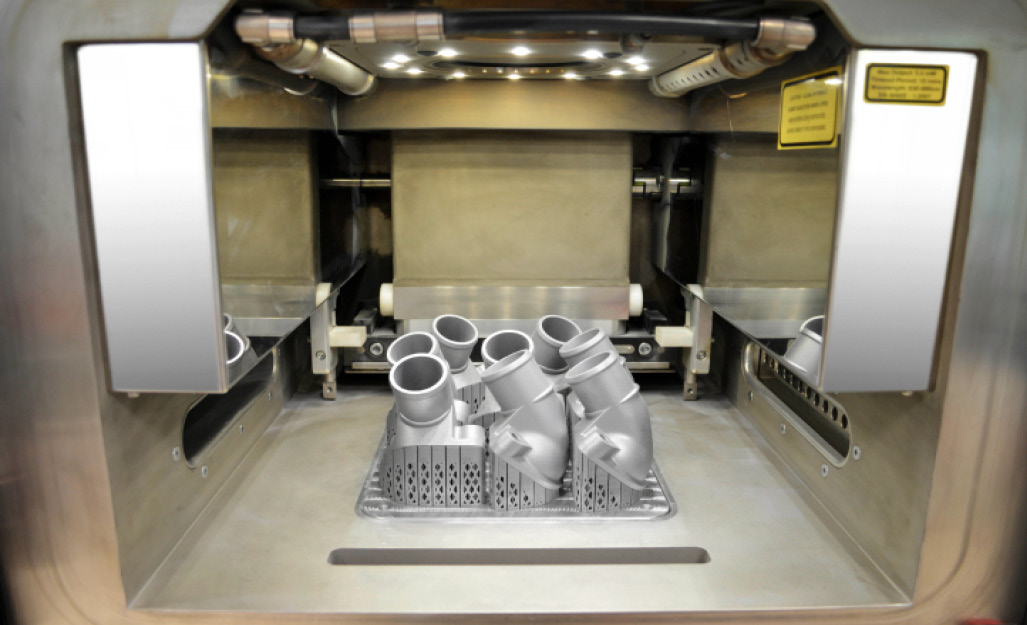

Daimler division prints first spare truck part of metal

A European sister operation of Daimler Trucks North America has taken 3D printing to the next stage: Production of heavy-duty model parts, starting with a thermostat cover.

Read MoreDaimler, Rolls-Royce commit to further MTU brand power development

Rolls-Royce Power Systems’ MTU business will continue to work with Daimler on developing and building high-speed Series 1000, 1100, 1300 and 1500 units that comply with the EU Stage V off-highway emissions standard. The engines deliver 100 to 480 kW and are to be available well ahead of the EU Stage V emissions standard scheduled for 2019. It will prescribe for engines, machinery and equipment a reduction not only in soot particulate mass but also number. MTU engines are to meet the more stringent emissions limits by deploying an additional diesel particulate filter. Further in-engine innovations will also be instrumental in lowering fuel consumption.