Workforce safety, input and growth potential carry the day at new Knife River Prestress Division flagship

BY DON MARSH

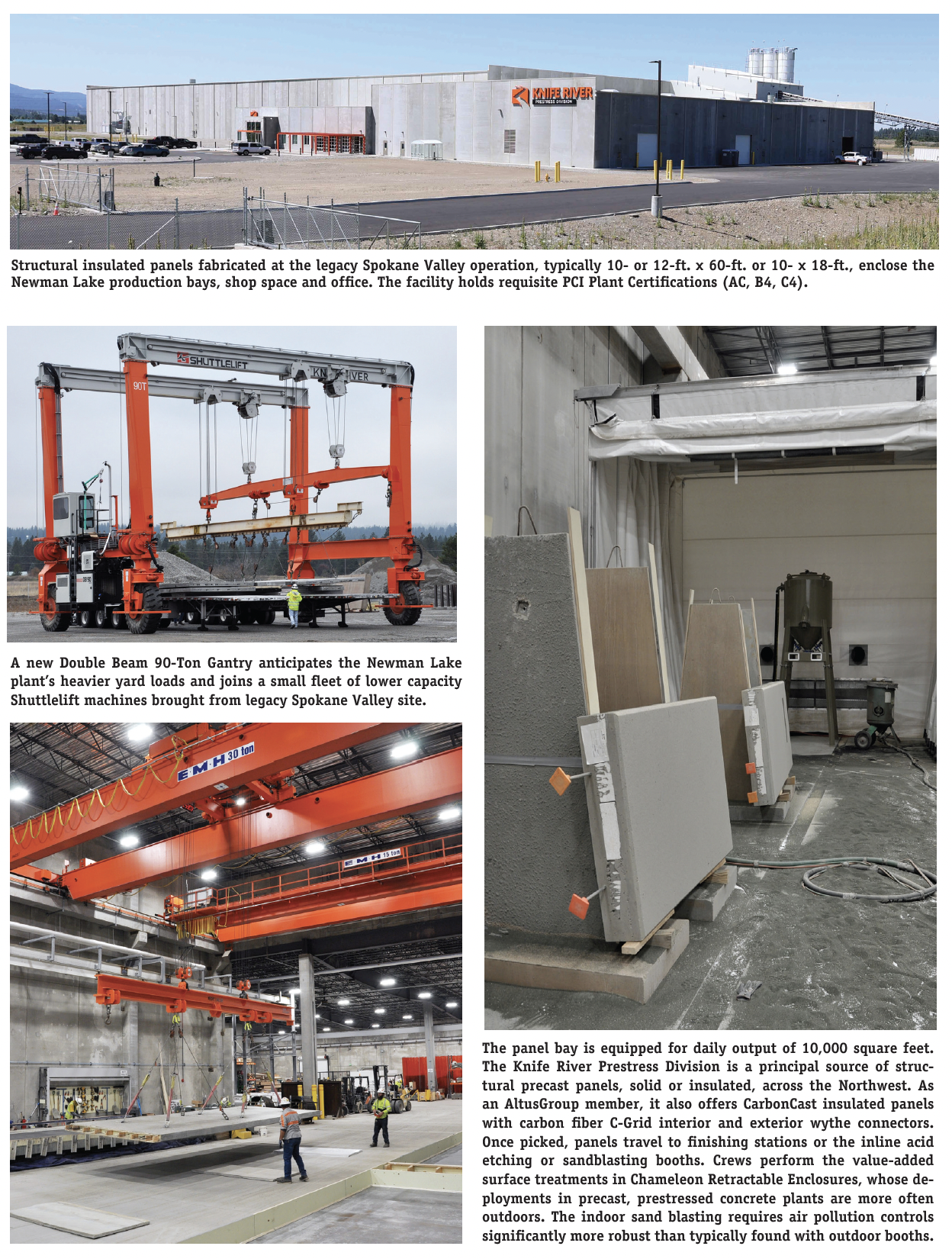

A new high-bay structure a stone’s throw from the Washington-Idaho border is poised to emerge this decade as the most productive precast, prestressed concrete facility on the West Coast. With nearly 200,000 square feet under roof on a 45-acre site, the Knife River Prestress Division operation in Newman Lake, Wash. is among the largest greenfield facility investments in the 32-year history of Bismarck, N.D. parent Knife River Corp.

“This state-of-the-art facility sets a new standard for precast, prestressed production in the Northwest,” says Knife River President and CEO Brian Gray. “It allows us to provide competitive building and infrastructure solutions in a safe, controlled environment for decades to come. It’s an investment for today and for the future, and it reflects Knife River’s commitment to growth and our core values of People, Safety, Quality and the Environment.”

Charter equipment, coupled with future automation outlays, will enable Knife River Prestress to escalate an architectural and structural concrete order log of work across six Pacific Northwest and Intermountain States. And sustainability is at the heart of all of it. The facility would be the first North American precast plant to carry certification under Concrete Sustainability Council, Geneva, joining four Heidelberg Materials ready mixed and aggregate plants in the Seattle and Phoenix markets. CSC certification reflects candidate operations’ success in Management, Environment, Social, Economy audits, and is gaining global acceptance as a responsible sourcing indicator. Among auditing process and certification benefits, Council officials cite productivity improvement, environmental protection, climate impact reduction and biodiversity preservation.

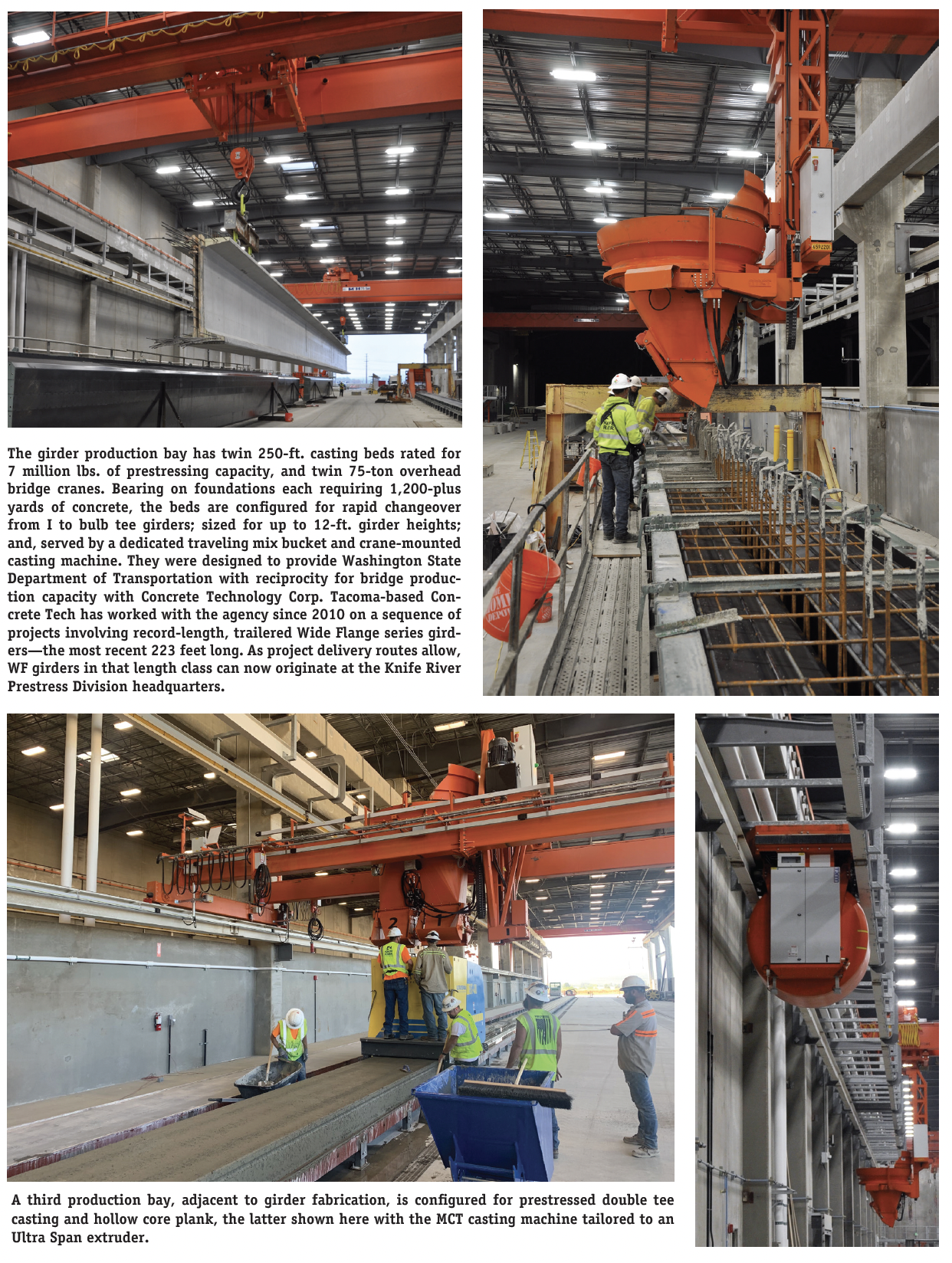

Knife River Prestress auditors will find much to recommend on the Newman Lake operation’s sustainability scale: Electric material and product handling equipment to curtail diesel consumption. A closed-loop hydronic heating system, upgraded from a “once-through” steam alternative, to maximize precast concrete curing efficiency. A recycled process-water system to cut fresh water use by half as measured against legacy plant benchmarks. Carbon dioxide treatment of all settled process water to relieve workers of high pH liquid exposure when performing routine plant cleaning and maintenance. And, structural precast sandwich panels, along with interior precast columns, to support a roof ready for a four-acre solar array.

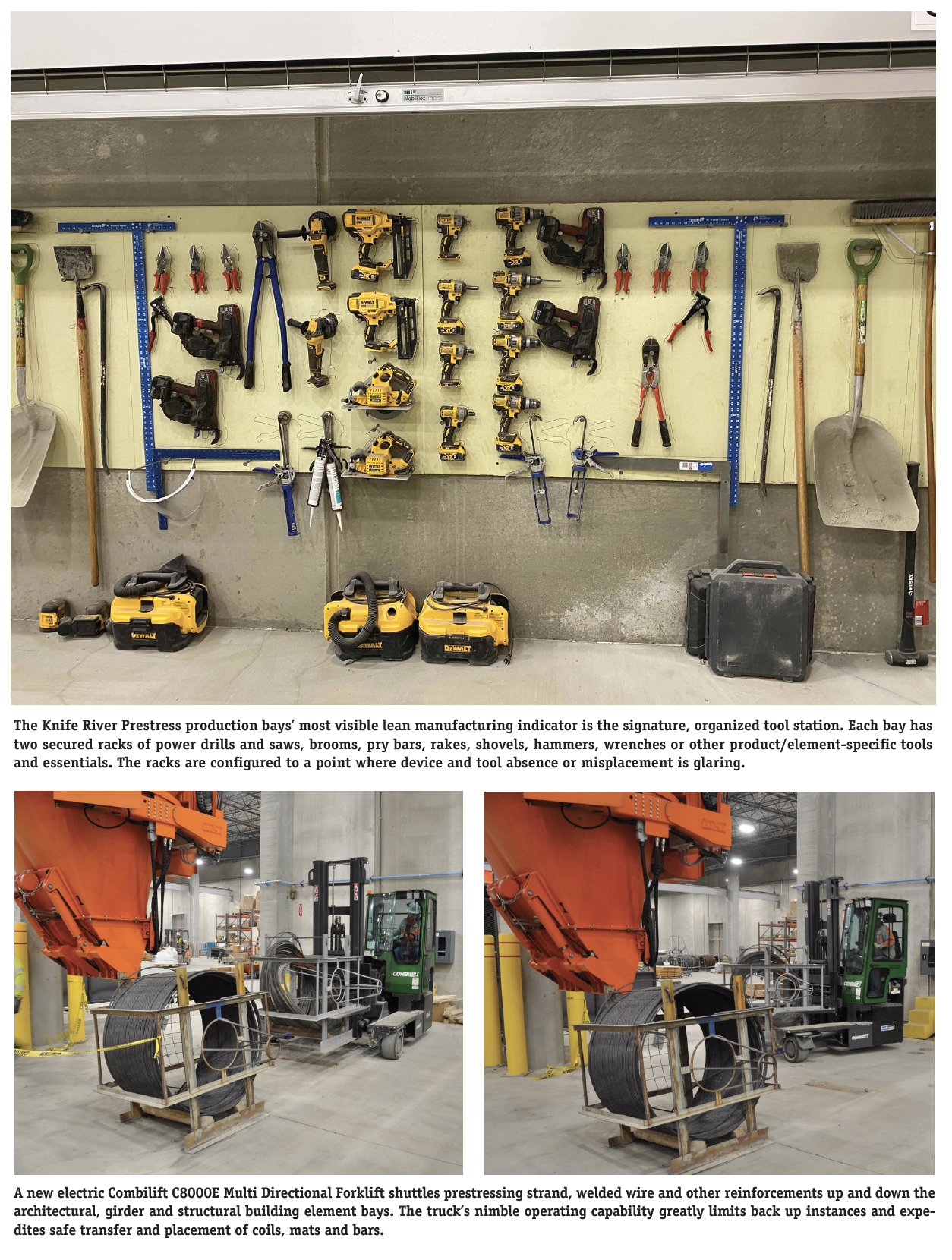

The facility includes an enclosed batch plant with twin 3-yd. planetary mixers combining for 100 yards’ hourly output; automated concrete delivery buckets traveling 450 to 490 feet of rail along one fully and two partially enclosed production bays; sprawling bed space for architectural and structural building panels, solid or insulated; twin, 250-ft. prestressed bridge girder beds; 400-ft. hollow core bed; the lifting muscle of a single 15-ton, three 30-ton and twin 75-ton bridge cranes, all with 32-ft. hook heights; and, a new 90-ton mobile gantry crane. Principal equipment or machine suppliers on the Newman Lake operation are American GeoThermal, EMH Inc., Helser Industries, Kraft Curing System, Matec America, MCT Group, Sicoma North America, and Ultra Span Technologies.

“This operation has capacity to supply major building and infrastructure projects while leading the industry in technology, working conditions, and environmental responsibility,” says Knife River Prestress Division VP and GM Peter Gay, a veteran of Oldcastle Precast and Lafarge North America. “As commercial building owners bring new demands and requirements for their facilities, and infrastructure ages across North America, the construction industry needs innovative concrete producers driving advancements in safety, quality and sustainability.”

Stepped up safety provisions are evident in major Newman Lake plant budget items, he adds, starting with construction of enclosed space for building panel architectural finishes, including acid etching and sandblasting plus girder preparation.

OVERCOMING OBSTACLES

Months prior to the new facility’s June 2021 groundbreaking, Knife River Prestress management eyed outside project assistance. Internal resources at the predecessor location in nearby Spokane Valley were fully consumed by an order log swelling with projects in the immediate Washington and Idaho Interstate 90 corridor, then one of the country’s hottest construction markets. The producer enlisted Texas-based PA/PO Industrial Systems LLC in an engineering, procurement and construction role. Big thinking commenced by owner and contractor alike.

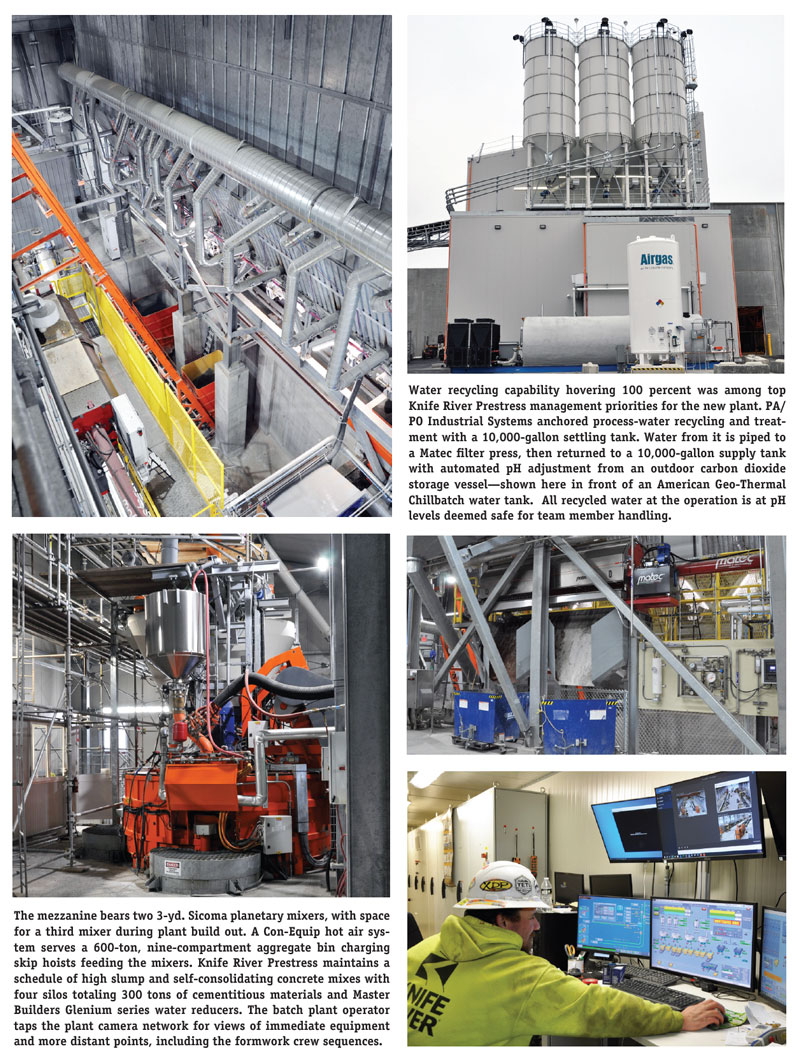

The new Knife River Prestress manufacturing facility opened in August 2023. Three years of design, construction, equipment installations and production trials saw pandemic and post-pandemic supply chain, labor and manufacturing disruptions, plus jaw-dropping freight rate spikes. Most members of the new plant’s seasoned production team shifted from the Spokane Valley site. They entered a facility utilizing lean methods to reduce wasted movement, from material procurement through finishing. Production crews have the accommodations and tools to demonstrate how lean methods equate to a sharp reduction in repetitive tasks and idle or wasted time—in turn improving man hour per ton metrics. The lean manufacturing quest bears on three pillars:

- Plant enclosure space. PA/PO engineers widened and lengthened the three production bays beyond normal expanse, ensuring that panels, girders, hollow core plank and other elements travel under roof until fully or near-fully prepped for final storage. Nowhere is the extended space more impactful than the panel bay. There, crews transfer panels from beds to patching or prep stations, or in-line acid etching and sandblasting booths. Built at considerable additional cost, the booths eliminate the need for production crews to repetitively handle or tend to panels with the value added finishes.

- Concrete mix delivery infrastructure. The new Knife River Prestress facility is one of a handful of North American plants equipped with MCT 3-yd. mix delivery buckets and casting machine hoppers. They combine to shorten the window of mixer discharge gate opening and mix flow into formwork. The batch plant’s two speedy planetary mixers ensure that the mix delivery buckets are charged at rates minimizing production crew wait times.

- Crew and tool visibility. Knife River Prestress managers and PA/PO engineers devised a 50-camera network monitoring all precast element production phases. Multiple-view screens are tailored to specific points or areas to expedite manager and supervisor communication, response or action. Although not initially hailed among crew members, monitoring regimens help track potential safety matters and challenge managers or supervisors to rethink procedures when footage reveals correctable patterns of work repetition and inconveniences leading to lost or wasted time.

Changes or improvements advancing lean manufacturing objectives dovetail another new Knife River Prestress protocol: A communication board hosted on the Smartsheet enterprise work management platform. The digital board is programmed for staff seeking to express concerns, offer ideas for improvement, nominate coworkers for recognition, and identify candidates for weekly rounds of gift cards. Responses to staff postings are designated to human resource, engineering, sales and production managers. Concerns are tasked to the appropriate department to answer routine questions and respond to requests for action on safety, productivity or other operational matters.

“The communication board is an inclusive tool open to all team members,” notes Knife River Prestress Engineering Director Dusty Andrews. “It gives them a vehicle to let them know they are being heard. Communications can have the reverse effect if employees are invited to submit comments and suggestions, then repeatedly see no action. The key is to make a process easy to navigate and provide timely, constructive responses.”

PEOPLE-FIRST

Before experiencing neatly configured formwork or reinforcing steel shops and a hardware preparation station serving three architectural and structural production bays, visitors at the Knife River Prestress headquarters entrance see the tables turned on a past corporate mindset: Traditional management perks, starting with office privacy, have been streamlined in favor of facilities and furnishings ensuring workforce comfort, pride and job satisfaction. Modest administrative, sales, engineering and production staff accommodations include two rows of five uniformly sized 10- x 12-ft. offices flanking two sets of eight cubicles and a 30-ft. conference table in open space immediate to the reception desk. The offices have floor to ceiling glazing and sliding glass doors free of name tags. Solid doors are limited to personal changing rooms within a unisex locker room and at all interior or exterior production area entry points. The open office floor plan and shared spaces foster collaborative communication among a diverse mix of frontline workers and leadership, part of a “people-first” culture.

True to that ideal, Knife River Prestress management and PA/PO staff scaled back an initial 19,000 sq. ft. office master plan to one just under 12,000 sq. ft. The change freed up project budget for workforce-skewed upgrades, topped by a sprawling break room with a grid of eight microwave ovens and other food preparation provisions approaching those of a commercial eatery. Three overhead doors along the front or east elevation allow the break room to function with an open air vibe, weather permitting, where employees can enjoy outdoor space without having to leave the property. Cornhole boards, built by a Prestress Division carpentry ace, flank the overhead doors and remind staff that toiling is not the only thing on management’s mind.

“We really wanted this facility and its proximity to the old location to be about the employees—a place where they want to be,” says Director of Accounting and Admin Annie Saye. “A strong focus on our workforce will enable us to keep pace with continued growth in demand for prefabricated building and transportation elements.”

Commercial Director Blake Johnson notes how attention to employees helps with retention and makes a positive impression with existing and potential customers, especially in the technology sector, adding: “We have seen the benefit of demonstrating shared people-first values with many of our industry leading customers, and have received feedback on how our commitment to people sets us apart. We want all our partners to know they are in business with a company that does things the right way, invests in our people, cares about their safety, and is committed to operating with integrity.”

FIRM LEGACIES

The Prestress Division is a unique profit center within New York Stock Exchange-traded Knife River Corp. (KNF), whose cement distribution and aggregate or ready mixed concrete footprint outside Washington stretches clockwise to Montana, the Dakotas, Minnesota, Texas, California, Hawaii and Alaska. Knife River Corp. succeeded Knife River Construction Materials upon a resolutely successful June 2023 spinoff from MDU Resources Group, also based in North Dakota.

The Prestress Division sustains the traditions of two late-1950s startups that helped solidify the market today. Each played pivotal market development roles for precast, prestressed concrete in the Northwest and minted two eventual PCI Chairmen: Richard Imper in 1996, Chuck Prussack in 2016. The Newman Lake plant replaces a facility that Spokane’s Murphy family developed under Central Pre-Mix Cos., one of the region’s best known ready mixed concrete and aggregate producers. Oldcastle Inc. acquired Central Pre-Mix in 1997, operating Washington and Idaho ready mixed and sand & gravel plants under the Materials division and CPM Prestress under Precast.

Knife River Construction Materials acquired the Spokane Valley plant in early 2020 as Oldcastle Precast sunset its architectural and building systems market positions in favor of drainage and utility structures at the core of the rebranded Oldcastle Infrastructure. Knife River management moved on the precast, prestressed plant mindful that relocation to a greenfield site was imminent. Subsequent to the acquisition, Oldcastle Precast/CPM Spokane General Manager Peter Gay was promoted to lead the Knife River Prestress Division, including the Harrisburg, Ore. plant and development of the new eastern Washington facility.

The Newman Lake operation complements its sister building and bridge plant in Harrisburg, originally operating as Morse Bros. Prestress. Knife River Construction Materials had entered the Pacific Northwest in the late 1990s by acquiring the Morse Bros. aggregate, concrete and roadbuilding business. The well-regarded Morse Bros. brand mirrored in Oregon’s Willamette Valley what the Murphy family built in Washington and Idaho.

“We knew our CPM Prestress successor facility was going to be filled by some of the most talented, committed workers in the Northwest,” affirms Peter Gay. “We needed it to match that standard of excellence. We believe we are setting a new standard for precast and prestressed production, delivering innovative building and infrastructure solutions for decades to come. We’re proud of the part we play in making our community stronger.”