CMC Ready Mix, a branch of the Construction Materials Company, started its third batch plant in Heber Valley just south of Utah’s prestigious Park City resort in July 2023 to provide concrete year-round for a fast growing, underserved market.

“We saw this as our opportunity,” says Taylor Larson, project manager, who joined CMC Ready Mix in 2021. “There was so much growth happening in the valley, and no new concrete batch plant had been installed there in the past 20 years. But the challenge was to find a plant that could work well in the harsh, long winter. At an elevation of 5,700 feet, Heber Valley is prone to early and late snowfalls and cold winter temperatures that settle into the valley floor.”

WINTER DURABILITY

CMC originally planned to acquire its third plant from a manufacturer they had previously used. However, when the supplier kept postponing the delivery date, CMC decided to pivot. Company owner Todd Cusick browsed the internet for a “cold weather concrete batching” when he stumbled upon Tecwill. He believed its Arcamix plant was exactly how he would design a cold-weather batch plant and was also intrigued by the inclusion of a twin-shaft mixer.

The Tecwill Arcamix 4.5 relocatable concrete batching plant is the largest plant in Tecwill’s production line specifically engineered for cold weather batching. Rather than being a traditional stacked stationary plant solution with costly prefabbed materials, the modular plant is designed for harsh environments with its integrated insulation, efficient containerization, and inclusion of a 6.8 MBTU/h non-boiler aggregate and water heating unit. It also features a twin-shaft mixer with a batch size of 6 cubic yards, six 45-ton aggregate bins, four cement silos, and a volumetric admixture system.

The enclosed batch plant is completely preassembled at the Tecwill factory in Finland. It includes pre-wiring, piping, thermal insulation and testing. The modular design dramatically reduces setup time, and can be relocated and moved, if desired, at any time of year. In fact, the quick setup was a welcomed surprise for CMC.

“Commissioning the Tecwill Arcamix batch plant happened in two weeks. Of course, this is exactly what they had told us. But due to our previous experience with promised manufacturer’s timelines, we conservatively hedged the timing,” Larson recalls.

GREENER TECHNOLOGIES

Along with the modular containerized plant structure, the entire plant design is engineered to minimize carbon emissions from cement production. Arcamix features Tecwill’s unique “flying” aggregate weighing system, which saves cement, increases production capacity, and reduces operating costs. It also comes with the OptiMoist aggregate moisture measuring system that uses one optical probe for all aggregate gradients, ensuring more accurate and faster measurements.

Tecwill also uses smart aggregate and water heating to lower energy costs. Hydraulic lids on the aggregate bins allow the loading operator to use a remote control to select the desired aggregate door and then close it, thereby keeping the material at the ideal temperature.

“Our customers absolutely love the higher quality and more consistent product we can now supply because of the nature of the twin-shaft mixer,” Larson says. “Even our drivers love it. The plant loads the truck in a very clean manner without much spillage, which helps them get out of the yard faster.”

CONSISTENT PERFORMANCE

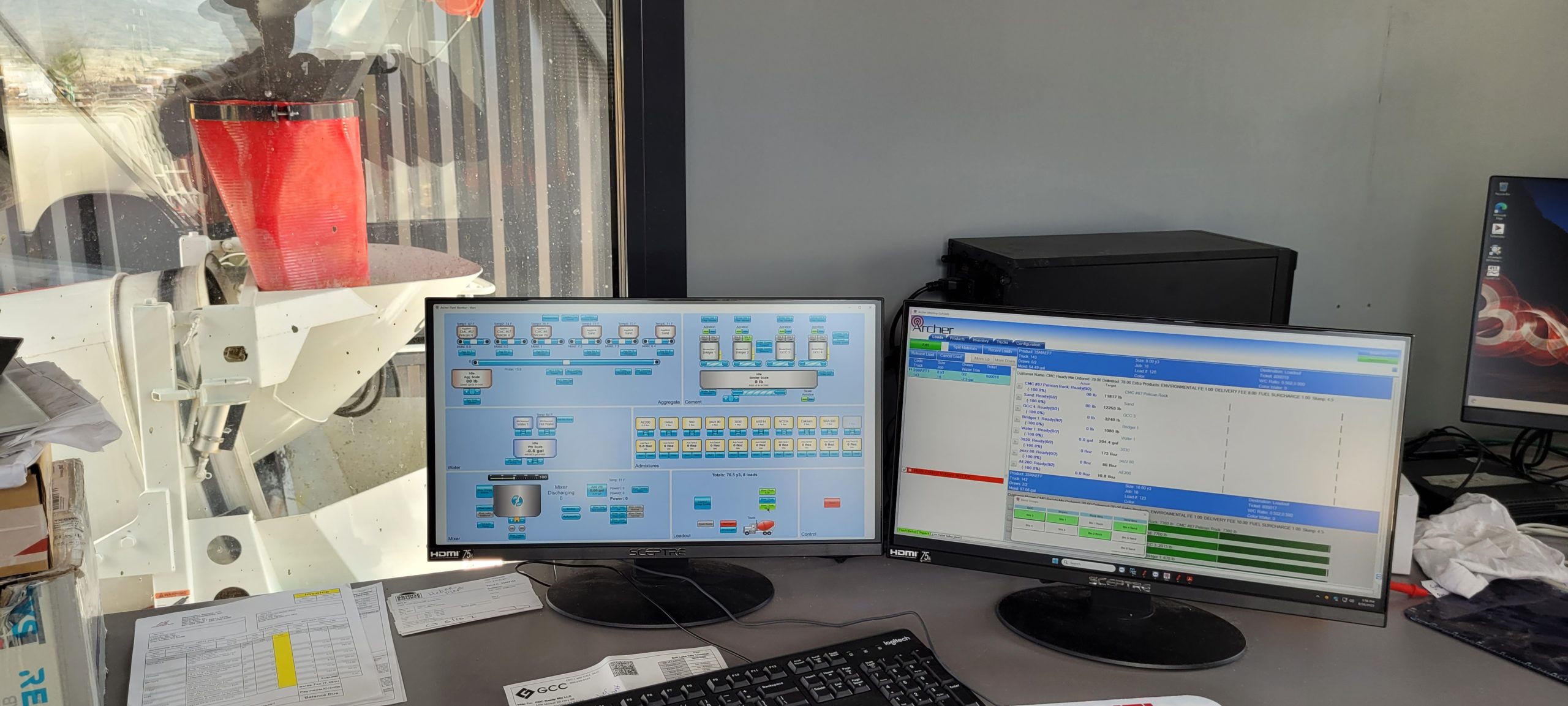

California-based Jonel Engineering supplied an Archer batch control system for the Arcamix plant. The system facilitates control of aggregate selection and combines speed, flexibility and connectivity into one system.

“CMC selected Jonel because of the great service they gave us with our last two batch plants. We were confident that they could integrate their system into this new batch plant,” says CMC Director of Operations Sam Cusick. “Jonel took care of everything needed to integrate their system with the Arcamix batch plant to achieve the performance we expected.”

Jonel made provisions for 240 I/O points. All discrete I/O was interfaced directly with Tecwill’s PLC. Along with all critical functions required to operate the plant, numerous I/Os were dedicated to monitoring various motor overloads, rotation direction, alarms, and plant voltage.

Arcamix’s unique “flying” aggregate weighing system (above) improves accuracy, increases production capacity and saves cement.

BETTER PREPARED

As this plant’s first winter sets in, CMC is extremely busy finishing foundation projects for residential and light commercial construction before pouring work declines during the cold months. Now that they’ve seen what the plant can do in the warmer months, the company has no hesitations about ramping up for large commercial projects.

Once CMC has experience of running Arcamix during the coldest months of the year, the company plans to replace an earlier underperforming plant with another one from Tecwill and add additional plants.

“We’re anticipating substantial growth in this area for at least the next 10 to 15 years,” Larson says. “Since CMC is a newer smaller, privately owned company, we need to be strategic with our resources to compete with the well-established, publicly owned suppliers.”

In Larson’s opinion, using Tecwill’s advanced technology to produce high-quality concrete has moved CMC into a competitive position in the market. “We’ve been very impressed by how well Tecwill has managed everything that could have gone wrong,” he says. “International manufacturers are often known to have longer lead times, difficulties with the different electrical systems and complications with metric versus imperial measurements. For me, it has been a great experience to work with Tecwill and see everything fit so nicely together.” — Tecwill, www.tecwill.com; Jonel Engineering, 800/432-4567, https://jonel.com