The National Ready Mixed Concrete Association 2023 Environmental Excellence Awards program honors nine plants. Now in its 28th year, the program offers producer members national recognition for outstanding contributions to protecting the environment and maintaining sound environmental management practices. It salutes operators that have not only met, but surpassed governmental compliance requirements and demonstrated a commitment to environmental excellence through plant and staff investment. A panel of judges reviewed each entry’s plant image submissions and written narrative covering site aesthetics, environmental documentation, training, water and air quality management, returned concrete plan, community relations, concrete delivery, and plant sustainability practices. Judges recognize three operations each in Eastern, Central and Western regions.

“Rule changes have made it easier for producer members to participate, making the Environmental Excellence Awards program even tougher, especially in 2023 when we saw a higher-than-average number of entries. These plants have demonstrated that they are the ‘best of the best’ when it comes to being good stewards of the environment,” says NRMCA Executive Vice President of Operations and Compliance Gary Mullings.

“This is an excellent example of the ready mixed concrete industry’s attention to environmental excellence,” adds President Michael Philipps. “These entries clearly demonstrate the incorporation of environmental management systems into plant operations.” Concrete Products joins the NRMCA team and Safety, Environmental and Operations Committee in congratulating this year’s honored producers and their exemplary sites.

EASTERN REGION

Concrete Supply Co., LLC

Pittsboro Plant • Pittsboro, North Carolina

system, then fl ows to a larger storage bay dubbed “Clear Well.” A carbon dioxide-based pH control device enables the plant to discharge treated process water in limited instances of the pit reaching full capacity.

Surrounded by hardwoods and abundant vegetation, the site exhibits the diligence of a plant manager, along with yard and driver team, in daily upkeep of production and fleet equipment, plus batching, loading, washout pit and concrete recycling areas. Truck cleanliness is top priority at Concrete Supply Co., where management and drivers view mixers as moving company billboards. Accordingly, drivers are provided with all of the necessary equipment to maintain their vehicles and strive for an annual clean truck award presented at each plant.

Concrete Supply’s environmental management system drives air and water pollution control measures key to compliance with federal, state or local requirements and permits. The EMS draws from monthly plant meetings, where the floor is opened for discussion of pollution control measures and procedural concerns. Managers find such gatherings especially productive as yard staff and drivers are recognized before peers, group discussion ensues, and the entire team is made to feel a part of a solution. Buy in promotes a positive response to future environmental management matters.

In annual plant audits, a corporate environmental manager reviews level of compliance with Air, Stormwater, and the SPCC plans. They also entail evaluation of best management and overall environmental practices. Audit results are discussed with the plant manager and crew and, when warranted, a corrective action list developed along with follow-up inspection target.

Concrete Supply’s community support is evident in fleet graphics promoting causes, organizations or themes from Watch that Child, Just Say No to Drugs, Support Our Troops and Levine Children’s Hospital to Support Special Olympics, Breast Cancer Awareness, and Support our Fire Fighters. The producer is also recognized as a Pace Setter company for its contributions to the United Way and has also earned the United Way of North Carolina Employee Spirit Award.

Pittsboro has the capability to recycle process water for concrete batching and/or mixer washout. All process water settles in a pit system, then flows to a larger storage bay dubbed “Clear Well.” A carbon dioxide-based pH control device enables the plant to discharge treated process water in limited instances of the pit reaching full capacity.

EASTERN REGION

Maschmeyer Concrete Company of Florida

Taft Plant • Orlando, Florida

The Taft team keeps this seven-year-old, seven-acre operation in impeccable condition, underscored by the frequency of heron, sandhill crane, owl, osprey, deer, wild turkey, turtle, bunny and Florida gator sightings. Exercising strict daily and weekly best management practices translates into excellent housekeeping, being a great neighbor, high employee engagement, and a sense of ownership in a home away from home.

Routine upkeep measures, proactive walkthroughs, and inspections with electronic tools help streamline permit compliance; conserve resources; and, provide a clear picture of the operation and adherence to maintenance plus environmental, health and safety policies. An environmental management system upgrade to Intelex has centralized permit tracking and task reminders. Concurrently, Maschmeyer Concrete has expanded its MaintainX software application to cover work order/action plans—pond cleanups, equipment replacement or site modifications/improvements among them. An interactive Learning Management System provides all team members with online Environmental Stewardship, Jobsite Practices, and Annual BMP, Air Quality, and Waste Management refresher courses, along with “Green Leaf Alerts.”

Stormwater is collected onsite in a multi-pit settling system, the cleanest water flowing over weirs into a contact pond and ultimately to the final pond. Oversized ponds at Taft allow recycling of collected water for aggregate sprinkling, ground washdown, slumping, exterior truck rinsing and/or use in select mix designs, all combining for significant reduction in municipal water consumption. Process water is contained in a concrete lined, multi-cell closed loop system, and only reused for drum washout.

Taft plant management is keen to neighbors and surroundings. With an eye to sediment control and track-out reduction, the plant is completely paved, while hauler and mixer traffic are kept separate. A pit near the exit takes in all water and sediment from the driveway and slump racks. For dust suppression, material bins are placed at the back of the property; piles are sprinkled and not overfilled. Grounds are washed daily, and an outside sweeping service maintains the primary access route.

The Taft plant will soon follow sister operations’ deployment of the water- and time-saving Shumaker Load and Go truck wash system.

To demonstrate concrete binders’ evolving profile, Maschmeyer Concrete built the Taft plant around a schedule of 70/30 slag cement and Type I portland (foundation mixes), plus 50/30/20 Type I portland, slag cement and fly ash (pavement and wall mixes) blends.

EASTERN REGION

VCNA United Materials LLC

Sanborn Plant • Sanborn, New York

Decorative, pattern-stamped bin blocks along the front property elevation indicate attention to plant aesthetics from a ready mixed concrete producer in tune with its community and local causes. The blocks are the product of a returned concrete handling strategy at the Sanborn plant. Like other VCNA ready mixed operations, it is bound by a corporate Environmental Management System that underpins air and water pollution control measures, plus continuous improvements in permit compliance measures. Among EMS directives is storm and process water capture, settling cycles and diversion to a 10,000-gal. underground cistern. That vessel feeds post-loading rinse procedures for mixer drivers along with aggregate stockpile spraying devices.

Water management and recycling are among long-held Sanborn plant sustainability practices. More recently, the facility has extended such measures by adopting St. Marys EnviroCem Portland-Limestone Cement as standard in all orders unless mix designs specify otherwise. The branded Type IL binder enables VCNA United Materials customers to promote finished slabs and structures of lower than normal carbon dioxide emissions intensity.

One of the newest additions to the VCNA United Materials fleet is a themed mixer saluting all five armed forces branches.

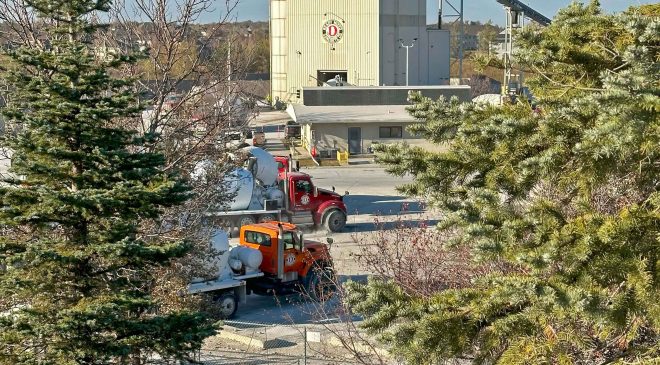

Seasoned delivery workhorse repurposed for dust management duty.

CENTRAL REGION

Cemstone Concrete Materials

Worthington Plant • Worthington, Minnesota

Tucked away in western Minnesota farmland, the Worthington plant is entirely enclosed and additionally shielded or screened by perimeter berms and newly planted trees. A large, lighted Cemstone sign on the rear elevation conveys a message of professionalism and quality to the community and Interstate 90 drivers.

Behind the operation’s extensive aesthetic and architectural treatments is an environmental management system, anchored by the Microsoft Teams platform. It enables sharing of documents in real time and instant access to inspection forms for staff or managers tasked with air and water quality monitoring and documentation. Across Worthington and sister sites, Cemstone conducts annual training for proper fueling and spill response procedures, SWPPP content, and water quality management. Specialized training extends to topics or areas such as new truck features, admixtures and cementitious materials.

The Worthington yard design is a case study in water pollution control and water recycling: The washout, batching, and rinse-down areas form a tight triangle for easy gray water conveyance through a weir system. Recycled gray water is used to wash out truck drums and, as specifications permit, batch fresh concrete. Stormwater is directed through swales into a pond that serves as a wildlife habitat.

Cemstone strives for new ways to build sustainable and environmentally friendly facilities. The concrete slabs at the Worthington plant, for example, were cast with Latitude, a performance-based concrete mix that eliminates reinforcing steel and provides extended joint spacing. The facility’s horizontal and vertical concrete elements exemplify Cemstone’s commitment to providing high-performance, low-carbon mix options.

Batch operator gauges weir water usage from previous month, along with a sample’s specific gravity.

CENTRAL REGION

Ready Mixed Concrete Co., a CRH Company

Elkhorn Plant • Elkhorn, Nebraska

Diverse native tree species play a crucial role in the ecosystem surrounding the Elkhorn operation and afford various environmental benefits, led by noise buffering and visual shielding. Additional abatement stems from batch plant configuration in a single structure. The property itself is adjacent to the City of Omaha’s Lawrence Youngman Lake Recreation area. Respecting visitors and neighbors alike, plant staff takes proactive measures to ensure that yard track out normally associated with a concrete operation is next to none.

An on-site pond serves a dual purpose at Elkhorn: It facilitates recycling, consistent with a corporate commitment to water management and conservation. Secondly, it contributes aesthetic value by raising the site’s visual appeal. A comprehensive water recycling program significantly contributes to reducing water consumption and environmental impact. Plant staff members have incorporated methods to recycle water, both for internal processes and concrete production. In addition to washout water recycling, management has implemented a new approach to repurpose the retention pond water. Up to 5,000 gallons of that water is consumed daily when used at rate up to 10 percent in batch water volumes. The pond also supplies water for dust control and aggregate stockpile sprinkling.

The Ready Mixed Concrete Co. environmental management system is well-structured and organized to streamline compliance efforts. A program called Risk-Connect houses all of the site’s environmental permits and related compliance plans, while facilitating timely inspection document completion and delivery. A corporate environmental manager performs a comprehensive site inspection annually, reviewing permits and checking team members’ knowledge of best management practices, plus proper oil, stormwater and hazardous material handling.

Continuous education plays a vital role in bolstering an environmentally conscious workforce at Elkhorn and sister operations. To that end, team members actively participate in monthly environmental training sessions. These “toolbox talks” provide opportunities to address specific environmental concerns, review best practices, and promote an environmentally responsible work environment.

A specially designed ramp that facilitates the transfer of leftover concrete from one mixer truck to another. Regardless of location in the yard, drivers abide a five-minute maximum idle.

The Elkhorn site harbors 100-plus trees planted by staff and a productive body of water respecting the adjacent Youngman Lake.

CENTRAL REGION

VCNA Prairie LLC

Yard 21/Glenview • Glenview, Illinois

The plant blends into a surrounding neighborhood, including commercial areas built on parcels of the former Glenview Naval Air Station, closed in 1995. The north suburban Chicago facility is surrounded by a block wall with planted vines and mesh screened fence for aesthetics and dust control. A dedicated water truck circulating the concrete production areas contributes further to dust control and is indicated in the Yard 21 Fugitive Particulate Operating Program (FPOP) under the VCNA Environmental Management System. Much like an SWPPP, the FPOP is a written set of procedures and ensures compliance with the facility’s Illinois EPA air permit.

VNCA officials hold plant staff-wide training sessions to cover dust control, storm and process water capture and treatment, spill management, truck and chute cleaning at the plant and in the field, along with other EMS objectives. In addition to containing and reusing nearly all storm runoff and process water, Yard 21 is equipped for 100 percent recycling of returned concrete. After mixer trucks windrow returned mixes, the yard crew crushes a blend of hardened concrete with reclaimed concrete pavement, netting road base widely approved in the northern Illinois market.

Interceptor trench along the east side of the property conveys water from dust suppression and truck washing to a retention pond. Onsite crushing assures 100 percent returned-concrete recycling.

WESTERN REGION

CalPortland Company

Rio Rico Ready Mix Batch Plant • Rio Rico, Arizona

Drivers, yard team members and plant managers muster on a Saturday morning for annual training session.

Plant employees have redefined the Rio Rico experience. They plotted and planted a pollinator garden, near the property entrance and in front of the office, then built a gazebo, thanks especially to a carpentry-wise driver. The structure has proved a gathering area for employees and visitors, including those eager to observe how the garden—complete with a local Girl Scout troop’s recent plantings—is attracting bees, butterflies and hummingbirds.

The aesthetic and functional features that welcome Rio Rico staff and visitors are matched with Environmental Management System deliverables. Spanning all plant areas, it has sealed a paper to electronic documentation transition, streamlined inspection routines, and saved many hours for an environmental manager assigned to site audits. One of the manager’s top priorities is water conservation. Rio Rico batch plant water drains into a weir and is drawn into tanks; yard crews can access them by standpipe for water reuse in dust control and/or mixer drum rinsing.

Management has further plans to cycle water from aggregate stockpiles, where it typically puddles and infiltrates into the ground. A concrete sump will be built to collect the water and a pump installed to redirect it back onto the stockpiles. Other Rio Rico air quality and dust control measures include haul road passes with a water truck; silo top dust collectors; and, a mixer truck load out baghouse. Batch operators adjust material sequences during truck charging. Cement tanker drivers follow offloading protocol (10 psi maximum) to ensure proper equipment functioning.

The Rio Rico plant was recognized for Gold-Level Arizona Department of Environmental Quality Voluntary Stewardship Program renewal. Agency staff visited to present the award and salute the continued pursuit of environmental excellence.

WESTERN REGION

Heidelberg Materials South Texas Concrete LLC

Brookshire RMC Plant • Brookshire, Texas

The producer’s newest location is strategically located on 12 acres to service ever-expanding residential and commercial development in and around the City of Brookshire. Plant construction began in 2021 and entailed a high level of engineering, surveying, permitting synergy, operations input, and crew execution. Approximately 1.2 million cubic feet of soil were excavated for drainage/topography/fill specifications to maximize stormwater capture and a vegetative perimeter.

The Brookshire RMC Plant was designed and built with an eye to seasonal drought conditions common in the Lone Star State. The entire site is graded such that 90 percent of all stormwater and 100 percent of process water drains to a weir pit system and outflows to a catch pond for recycling. An engineered water retention feature, the latter can hold 5 million-plus gallons of water for reuse and recycling in concrete production, drum washout, slump stand adjustments, dust suppression and ground surface cleaning. Wildflower seeds scattered around the catch pond embankment have blossomed and augmented slope stabilization.

The Brookshire plant abides a combination of environmental management system components including the Stormwater Pollution Prevention Plan, Spill Prevention Control & Countermeasure plan, Internal Audits, and the recently deployed ComplianceGo. The online platform affords managers and certain team members capability to conduct routine inspections, log maintenance items, assign deficiencies for corrective actions, and utilize automatic recordkeeping for regulatory mandates. Team members follow standard operating procedures for fueling, drum washout, process water recycling, and returned concrete.

All returned concrete at the site is recycled. Material is used to make blocks for perimeter barrier installations, stockpile segregation, visual markers, and traffic control. Any excess returned concrete is confined to a secure berm, left to dry and properly harden before it is broken, crushed and hauled offsite by a third-party contractor that utilizes the material for road base. Near-term, Heidelberg Materials plans to construct a concrete crushing facility adjacent to the Brookshire plant to further improve recycling capacity and meet operational demands.

Heidelberg Materials considers training of all employees essential. Managers and plant staff receive annual environmental instruction and semi-annual refresher courses on air or water pollution control and waste minimization strategies. The producer is likewise committed to keeping all team members informed about new regulations, the status of the industry, and fiscal health of the company.

Mixer charging dust control.

Annual environmental management training.

WESTERN REGION

Heidelberg Materials South Texas Concrete LLC

Hardy Street RMC Plant • Houston, Texas

Located west of a residential neighborhood, north of the Interstate 610 loop and adjacent to the Hardy Toll Road, the plant is the producer’s only central mixed facility—equal to the demands of a top Texas market. Work bringing the site to its present state included construction of a five-bay weir pit water treatment and storage structure; pH control system installation; paving of all active plant and vehicle routing surfaces; truck and auto traffic segregation; plus, new entrance, traffic, and parking signage.

Environmental management system components operate synergistically to assist Hardy Street plant staff achieve regulation and permit compliance via regular inspections; pollution abatement device maintenance; identifying equipment deficiencies; and, corrective actions. Environmental audits note EMS variances or shortcomings while acknowledging areas of exemplary performance. All employees receive annual environmental training and engage in more frequent, less formal Toolbox Talks. Such gatherings address air pollution control, opacity, water conservation, waste management, stormwater pollution prevention, spill prevention and mitigation, and best management practices.

BMPs centered on dust control include the plant’s exclusive use of washed stone, which minimizes the presence of fine particles becoming airborne. Delivered sand has an average moisture content of approximately 6 percent, which also serves to minimize fugitive dust associated with handling and storing. The plant runs with a combination of air quality devices and practices (central dust and silo top dust collectors, overfill alarms, filling procedures), along with watering and sweeping routines. Air quality measures extend beyond the gate: Prior to departing the Hardy Street plant, mixer trucks are rinsed to prevent track out and potential road dusting. Rinsing protects other vehicles and drivers during the order outbound phase, and instill ownership in drivers, all of whom participate in the NRMCA Jobsite Chute Rinse Off video training.

Heidelberg Materials prides itself on being an active member of the communities in which it operates and regularly assists organizations. The South Texas Concrete division has introduced several theme trucks supporting Know Autism, A Foundation for Children with Autism; Mothers Against Drunk Driving of Southeast Texas; Hudson Folkerts Memorial Foundation; military veterans; and workplace safety.

ZERO-DISCHARGE FACILITY

Heidelberg Materials aims to harvest and recycle all Hardy Street plant stormwater and process water, primarily in the 72,000-gal. weir pit. Settled water is used for truck rinsing and yard dust control. After the plant was up and running, a natural water feature emerged and has become a micro habitat for small vegetation and wading birds, including egrets plus the occasional heron. In facility planning stages, management looked beyond permit requirements for stormwater and process water treatment, electing to install an advanced pH monitoring and control system. It incorporates conductive probes, submersible pump, holding tank, electronic control board and acid injection process to constantly neutralize higher alkalinity in the recycled water.