Two acronyms go well together, ERP (Enterprise Resource Planning) and BIM (Building Information Modeling). But what is the relationship between BIM & ERP? Why is it important to understand both? And what possible interest could more software have to a precaster? BIM and ERP each represent one half of the whole software automation picture as it relates to precast concrete manufacturing. Integrated and taken together, BIM & ERP will provide precast producers the design, production control and financial management tools they need to fully take advantage of the coming revolution in building construction.

|

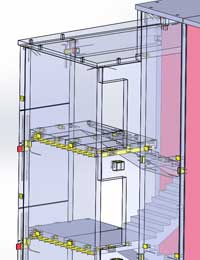

| As a design technology, a Building Information Modeling platform like StructureWorks enables architects and engineers to shape a project in full size, three-dimensional space on a computer. By calculating concrete mix, reinforcing steel and companion hardware requirements, and indicating floor, wall and column elements throughout a structure, a BIM program offers precast producers much time and cost savings potential. |

Don’t ask me exactly how BIM works … that’s why we’re going to talk to Wayne Maiuri of StructureWorks, a developer of BIM software and an expert in the technology. For now, let’s start with the simple. Most readers are probably familiar with the concept of Building Information Modeling. Visiting www.wspgroup.com, I read a great definition of BIM recently: “BIM is the process of designing a building collaboratively using one coherent system of computer models rather than separate sets of drawings.” From the 30,000-ft. view, that doesn’t sound so bad, and actually sounds pretty neat. But then why do so many precast producers resist it so much?

Before we turn to our expert, let’s talk theory for a moment. Let’s talk about why BIM & ERP are so exciting together. BIM is a design technology and ERP is a planning and financial management technology. BIM allows a building to be built in full size, three-dimensional space, inside a computer. ERP lets you know how long it’s going to take, what it’s going to cost and how to account for the cost. With BIM, every system, every conduit, every duct, structural column, beam, wall, and water fountain has a place in the model. With ERP, the precaster schedules production to meet the project needs and manages finances to run the business. Never before have the architect, builder, subcontractor, and fabricator been able to work so smartly together during the design process to insure that when the building is actually built, there is a minimum of errors and changes. And never before have so many tools been available to fabricators to price, design, plan, produce, deliver, and financially manage their projects. BIM takes the guesswork out of estimating and could help you get more jobs.

In order to effectively use BIM on jobs, architects and builders need to assemble their construction teams during the design phase. If you know BIM, you are more than a precaster, you are a consultant. You design your product the way you know it needs to be fabricated, and that information becomes part of the BIM model. The industry is encouraging precasters to negotiate

contracts and be awarded projects during the design phase for this reason. You are finally able to be rewarded for the knowledge you bring to the table.

The BIM model contains the layout, mark number, size, volume and even the bill of material items for each piece. Your shop drawings are, to some extent, completed before the job even starts. BIM and ERP talk to each other. BIM provides the quantities of raw materials, ERP figures out the costs and plans the production based on the time it takes to produce each subassembly and each finished piece. BIM and ERP manage the production and delivery process; ERP manages your inventory, invoices for the job, and manages all financial reporting for the job and the company.

To talk about the state-of-the-art with regard to BIM and precast manufacturing, we turn to Wayne Maiuri of StructureWorks LLC, which offers a 3D, parametric BIM modeling software for structural precast design as well as Piece Tracker, an advanced project management tool that allows you to know the status of every piece at every stage of production. With thanks for lending a hand on understanding the BIM world and helping us non-BIMers see how this technology is affecting the industry, he engages in a question & answer session:

Can you elaborate on the simple definition of BIM that I have given above so that our readers can understand the concept and the technology?

WM: BIM stretches all to way from an estimating tool for acquiring work, to an owner’s tool after a project is delivered, and all phases in between. The common misconception

is that BIM is primarily a collaboration tool. Though there is great benefit as a collaboration tool there are many other layers that give a much higher return on investment to a company that produces precast.

|

| ERP programs equip precast producers with production planning and financial management technology tools to gauge a contract’s length of fabrication and delivery, cost accounting and net cost. |

Can you explain how specifically precasters are using BIM?

WM: There are a number of early adopters in BIM that are seeing the benefits by collaborating, and some are even gaining the benefit of pulling the information from the 3D model into other software packages such as ERP and product management software. Utilizing the information within the BIM software is very powerful and saves precast manufacturing companies a lot of time and money. There is also a large benefit of sending the 3D data to CAD/CAM technologies such as rebar benders, cutting tools, and laser projection systems. Each of these technologies allows the precaster to drive their manufacturing from the 3D model. Much less precast-specific training is required from drafting to manufacturing than people realize. Once implemented, manufacturers see huge productivity gains and designers see huge reductions in drafting time and, in many cases, elimination of drawings altogether. This provides the opportunity to reduce the amount of paper work, and start moving towards a paperless environment. As we progress to a 3D BIM-centric lifecycle, we are able to utilize data in new ways which will empower people and frequently improve accountability.

What are BIM standards?

WM: Currently there really aren’t any. Though BIM is not a new concept it is relatively new to the precast industry. Georgia Tech and the Charles Pankow Foundation are working to create the standardized Industry Foundation Class (IFC), a platform-neutral file type, that will allow the different CAD platforms to interchange 3D data and, just as importantly, Meta data for each 3D object between the CAD software companies. With that said, IFC is not BIM, but rather a tool that can be used to exchange BIM data. BIM is more of a concept that can be employed in many other areas of a company to develop interoperability between hardware and software systems.

Why are so many precasters resistant to the use of BIM?

WM: I believe there are three reasons:

- Education. BIM has been more of a buzzword in the industry for the last few years and there has been little education about the subject. Many people do not know that BIM can be extremely valuable, even in the smallest of precast manufacturing companies. The Precast/Prestressed Concrete Institute BIM committee is working to change this through webinars planned for 2014.

- Cost. There is a large investment in moving to these CAD platforms, ERP systems, product management software, and CAD/CAM capable hardware. Some companies are making the investments to move forward and these early adopters are seeing the benefits their initial and subsequent investments bring.

- Status quo. It is hard to change the status quo. 2D technologies and spreadsheets have been used for decades. They are a known quantity, and moving into this new world of 3D and data-rich tools holds a lot of unknowns for those who are the elite in the legacy technologies. I believe it is important for the precast industry to change the paradigm and progress to the same level that other manufacturing industries have.

What changes could take place in the industry to make BIM more accepted?

WM: I think education is a great start, and documented examples of the savings BIM brings to the precast industry will help. Once companies understand the productivity that can be gained in the office and in the plant, I believe they will embrace BIM and see it for its full potential, not just a tool for collaboration.

What do you see as the future of BIM as it relates to ERP?

What do you see as the future of BIM as it relates to ERP?

WM: As we tie our CAD systems with product management and ERP systems the future seems wide open. This is going to save companies a lot of time and effort in areas like measurement, accounting, and inventory control. Much of the data input has been, or will be, automated through these systems.

What should our readers do to learn more about BIM and prepare themselves to take on BIM projects?

WM: Keep an eye on the PCI BIM committee at the least. Participation in the committee would be even more beneficial. Reach out to the software providers to gain insight on this technology, and, most importantly, invest in the future, and challenge software companies to push BIM forward. Without the support of the industry this valuable tool will not grow to its full potential.

I couldn’t agree more with Wayne’s comments and insight. Understanding the potential in both ERP and BIM technologies starts with education. Technology is changing the world, and this includes the construction industry. Companies that invest in understanding how these technologies can help them be better at what they do will be positioned to win more business and satisfy ever more sophisticated and demanding clients.

Alan Barr is an industrial engineer with 25 years’ experience in the custom precast and dimensional stone industry. He is an organizational expert in management science and has designed and implemented workflow systems for custom stone and precast manufacturing plants. He is managing partner at PerfectJob ERP Systems, www.perfectjoberp.com. Wayne Maiuri is an application engineer at StructureWorks LLC, Orlando, Fla., with nearly 20 years’ experience in 3D CAD and CAD/CAM technologies. He has been in the precast/prestressed concrete industry for more than a decade, and spent seven years in the mechanical design fields of mobile military and material handling.