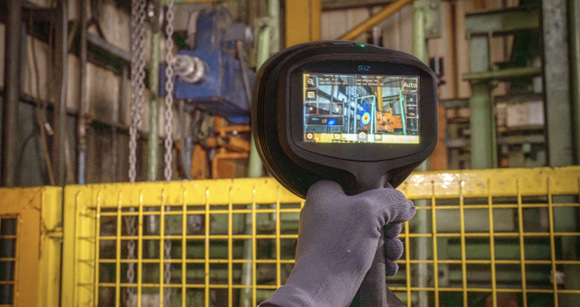

Company has expanded its versatile Si-Series of acoustic imaging cameras with three models engineered to detect compressed air or specialty gas leaks, mechanical faults, and partial discharges: the Si2-Pro, Si2-LD, and Si2-PD. The series offers industrial-grade solutions and addresses the top inspection requirements for manufacturing operations. The cameras are equipped to identify issues over longer distances, detect and measure with increased sensitivity, and produce more accurate classification of issues.

Improvements in acoustic camera picture quality include 12-MP color camera, 8x digital zoom, and LED illumination for addressing dark areas. The Si2 Series also has increased battery life to keep professionals in the field longer without the need for swapping power sources. Advanced automatic filtering identifies leaks by their sound signatures even in the noisiest of industrial environments. The new “mech mode” feature of the Si2-Series enhances site safety by enabling quick detection of mechanical issues, such as bearing faults, empowering professionals to rapidly evaluate conditions, identify problems, and implement solutions.

Plant professionals can swiftly identify mechanical, leak and partial discharge issues, then generate reports for urgent attention. On-camera decision support tools include mechanical defect measurement, classification and severity assessment of partial discharges, leak size estimation, and cost analysis. The Si2-Pro, the most comprehensive solution that combines the features of the Si2-PD and Si2-LD, actively lowers costs by addressing mechanical bearing issues and partial discharge on electrical equipment, and it also significantly cuts leaks in facilities to reduce expenses from compressed air and gas supplies. — Flir/Teledyne Technologies, www.flir.com, www.teledyneflir.com