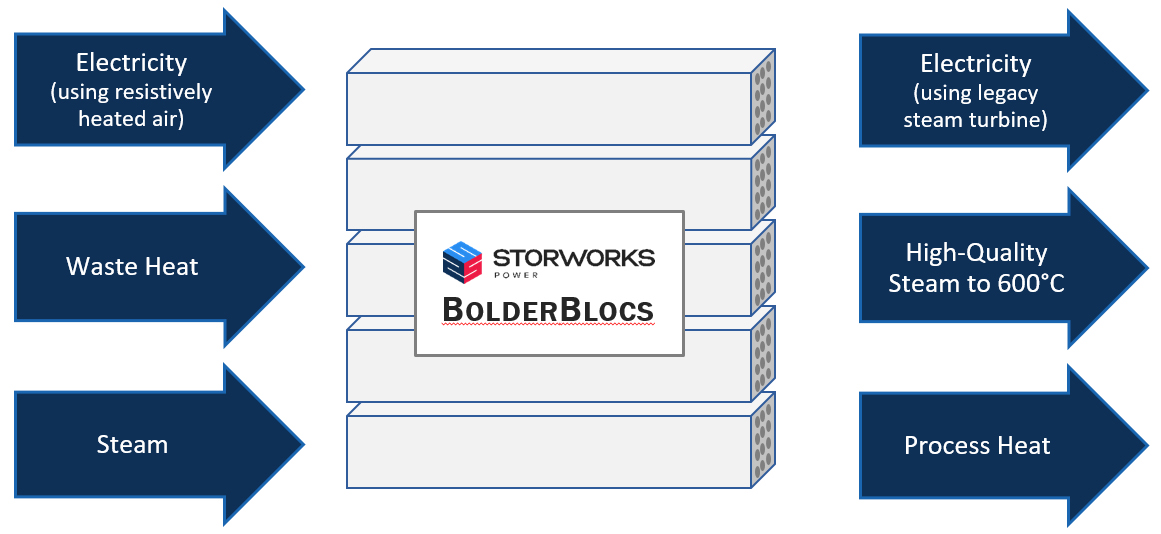

The Electric Power Research Institute has demonstrated the thermal energy storage performance of column-like, horizontally stacked concrete members, dubbed BolderBlocs by their Arvado, Colo.-based developer Storworks Energy, at the Alabama Power Ernest C. Gaston Electric Generating plant. Investigators devised a 10-megawatt hour electric energy storage solution, charged with Gaston Unit 5 supercritical steam output. Under their test assembly design, high-pressure steam flows through tubes to heat the BolderBlocs, which store the thermal energy until it is returned to the power plant by converting feedwater into steam to generate electricity in response to grid demand. At scale, the technology allows grid operators to store energy when it is not needed and then deliver it when it is most valuable.

EPRI and Storworks collaborated on the concrete thermal energy storage (CTES) demonstration with Alabama Power parent, Atlanta-based Southern Co., and Department of Energy backing. Researchers see the technology as applicable to existing or new thermal power plants running on coal, natural gas or nuclear, or concentrating solar power. The core technology can go beyond electric power to applications including decarbonizing industrial heat, a strategy pegged for lowering carbon dioxide emissions in cement and steel production. The pilot system, temporarily integrated into the unit at Gaston, proved the technology’s potential to store thermal energy for conversion to electricity when combined with thermal power plants. The original goals of the project were exceeded, as steam production at several pressure levels was demonstrated. More than 80 energy charge and discharge cycles were also successfully performed over 700 hours of total operation.

“Advancements in long-duration energy storage are key to unlocking the full potential of variable renewable energy resources on the path to net-zero,” says EPRI Vice President of Energy Supply and Low-Carbon Resources Neva Espinoza. “As the power sector navigates a highly complex transition, CTES could play an important role in efficiently delivering reliable and affordable electricity.”

“Southern Company is deeply committed to advancing the transition to a net-zero future,” affirms Senior Vice President of Research, Environment and Sustainability Dr. Mark Berry. “We are exploring the potential of CTES technology to help decarbonize electricity production [and] excited to be pioneering this groundbreaking research demonstration in collaboration with EPRI, Storworks and our subsidiary, Alabama Power.”

“Storage is increasingly critical in the shift to low-cost intermittent renewable energy, and the Gaston project represents an important milestone in advancing the commercialization of our technology,” adds Storworks Co-Founder Scott Frazer. “Our modular system can be tailored to a range of applications for both power plants and industrial decarbonization solutions.”

Related article

Energy Vault’s concrete behemoth anchors world first in power storage