The Environmental Protection Agency recently announced a $400,000 Small Business Innovation Research (SBIR) program Phase II grant enabling Santa Ana, Calif.-based Hydrova Inc. to advance work on black dross—a material frequently landfilled after primary aluminum recycling—for applications including cement clinker raw feed. Themed “Complete Resource Recovery and Hydrogen Production from Secondary Aluminum Processing Waste,” the grant extends a $100,000 Phase I contract under which Hydrova teamed with CTS Cement Manufacturing Corp., southern California neighbor and Rapid Set packaged material series proprietor, to incorporate dross-derived aluminum in calcium sulfoaluminate (CSA) binder production.

Recovery of alumina for clinker raw feed runs in tandem with Hydrova’s generation of high-purity hydrogen from dross and a companion waste, salt cake. Hydrogen provides a clean fuel source for a number of different decarbonization applications, including direct combustion, blending with natural gas, and fuel cell power. Ahead of the CSA cement raw feed testing, Hydrova identified a method for a 10-fold reduction in dross chloride ions, whose deleterious presence has traditionally hampered the waste material’s recycling prospects.

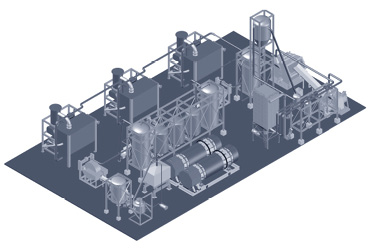

“The Phase II grant will support the commercialization of our DrossZero systems,” says Hydrova CEO Julian Davis. “By closing the loop in the aluminum industry, Hydrova is furthering United States’ leadership in advanced recycling technologies.”

PHASED PROGRESS

In their “Complete Resource Recovery” Phase I (December 2022-June 2023) summary and Phase II (October 2023-October 2025) outlook, EPA officials note:

- Reuse of dross as a raw ingredient for aluminum and cement production, along with hydrogen generation, helps achieve EPA National Recycling Strategy objectives aimed at improving the U.S. recycling system and reducing carbon dioxide emissions. There is a sizable and growing market for aluminum dross solutions as the recycling industry expands at a rapid pace. Due to both increasing waste disposal and raw material costs, aluminum recyclers seek better solutions to help improve their operating efficiency and sustainability metrics. Zero-waste dross recycling, coupled with hydrogen generation, provides a path to annual diversion of up to 1 million tons of waste from landfill and reduction of a comparable volume of CO2 emissions.

- Along with costing the industry billions annually, landfilling dross and salt cake additionally causes leachate, gas evolution, and explosion hazards. All can have a detrimental impact on human health and the environment.

- By repurposing materials within dross and salt cake, Hydrova can drastically decrease energy use and emissions. Recycling aluminum is more than 90 percent less carbon intensive than producing the metal from bauxite.

“California’s small businesses are leaders in creating innovative and practical zero waste solutions that have far-reaching benefits for communities,” observes EPA Pacific Southwest Regional Administrator Martha Guzman. Hydrova and two other Golden State SBIR Phase II grant recipients’ efforts to bring their technologies to market, she adds, “will advance the circular economy while reducing waste that ends up in a landfill and cutting greenhouse gas emissions.”

SOLIDIA CEMENT PRODUCTION CAMPAIGN FORGES AHEAD

CTS Cement Manufacturing Corp., California-based producer of Rapid Set and Komponent specialty concrete binders, recently completed the first of a series of planned production campaigns for Solidia Technologies, San Antonio, Texas. A low limestone binder that gains strength through exposure to carbon dioxide and the attendant carbonation process, Solidia Cement is made with the same raw materials as portland cement, but exhibits significantly eased CO2 emissions due to lower production temperatures and reduced limestone calcination. Measured against portland cement, Solidia Cement production equates to 30 percent lower CO2 emissions and 12 percent greater yield per ton of raw material.

“CTS strives to be at the forefront of innovative, sustainable cement technologies that are engineered for performance and high quality, and we’re thrilled to play a key role in helping to bring Solidia’s low-carbon cement to widespread commercial availability,” says CTS Cement CEO Ken Vallens, whose company is North America’s largest source of low-carbon belitic calcium sulfoaluminate and Type K shrinkage-compensating cements. “Our first production campaign with Solidia Cement was a tremendous success and demonstrated the true potential for this important technology. We are looking forward to working with Solidia on additional production runs in the near future.”

“With a proven track record of producing innovative and high-quality materials, CTS is an ideal partner,” adds Solidia CEO Russell Hill, Ph.D. “The company’s production campaigns not only showcase the commercial feasibility of Solidia Cement, but they also expand our network. We’re excited to continue to work with them to supply growing demand for our precast and supplementary cementitious material platforms.”