A proposed ASTM International standard, WK 73384, New Test Method for Evaluating the Tensile Performance of Fiber-Reinforced Concrete Using Cylindrical Specimens with Double-Punch Loading, holds the potential to open conventional fiber-reinforced and ultra-high performance concrete (FRC, UHPC) to a broader range of engineered construction conditions. The document is under ASTM Committee C09 on Concrete and Concrete Aggregates balloting and the work of C09.42 Subcommittee on Fiber-Reinforced Concrete.

WK 73384 test procedures measure specimens’ pre- and post-peak tensile strengths. “These properties serve as the fundamental characteristics of FRC and UHPC, playing a vital role in determining the capacities and failure modes of structural members constructed from these materials,” says ASTM C09.42 member and University of Texas, Arlington Professor Shih-Ho (Simon) Chao. “The double-punch test utilizes a simple apparatus and procedure, providing a convenient method for obtaining [pre- and post-peak] tensile properties. This method is well-suited for routine testing purposes and exhibits low variability in its results.”

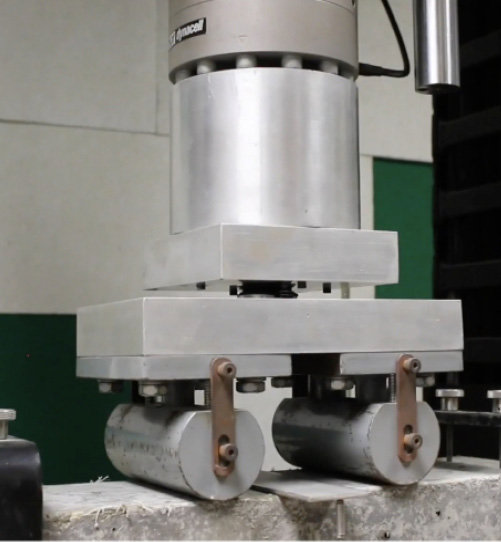

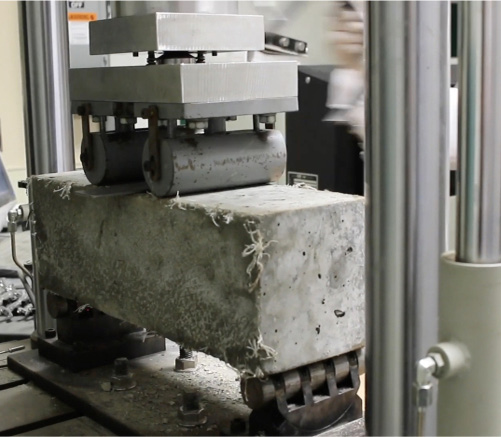

The double-punch test method (DPTM) is highly regarded having undergone extensive application by researchers the world over, he adds, positioning WK 73384 as a “helpful tool for quality control purposes and/or as a guide for serviceability and strength design.” The method entails loading a fiber-reinforced specimen in a compression testing machine through 1.5-in. diameter punches at each end. “This type of loading results in indirect tensile stresses on radial planes, leading to multiple cracks in the specimen,” C09.42 members explain. “Vertical movement of the testing machine is measured, providing a load-deformation curve from which the peak tensile strength and the residual strength at a specified post-peak deformation can be calculated.”

When measured against flexural test method results, WK 73384 authors observe, the DPTM offers a) truer tensile strength without being computed through back-calculation approach; b) a more averaged performance owing to development of a larger crack area; c) more opportunity for routine testing due to a simpler apparatus required for the procedure; and, d) evaluation of FRC in-place properties through drilled core testing.