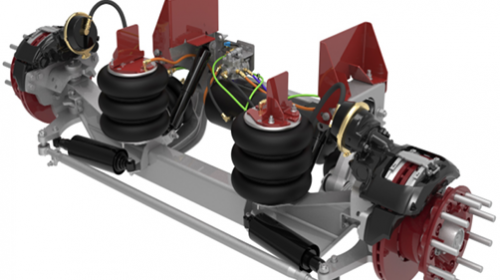

Manufacturer bills its ROI (Road Optimized Innovation) Auxiliary Suspension system as the first intelligent component of its kind, eliminating the guesswork for drivers of when to lift or lower and helping maintain maximum traction without axle overloading. The system is programmed to determine optimal tire-to-ground pressure and automatically respond to the vehicle’s wheel traction. In snow, mud and other challenging conditions, the ROI technology, working in conjunction with the vehicle’s ABS, gauges the absence of surface friction and reduce pressure as needed to shift the requisite tractive force to the drive axles.

“ROI technology is able to sense when the vehicle’s load has changed and automatically deploys or retracts the auxiliary suspension system as needed,” says Link Mfg. ROI Product Manager Eli DeGroff. “Unlike traditional all-on or all-off auxiliary axles, our smart suspensions are able to determine the load they need to bear and automatically adjust to precisely accommodate that weight.”

“If an auxiliary suspension system is engaged when not needed, it can cause the tires to drag, or ‘scrub,’ negatively affecting tire wear, fuel mileage and maintenance intervals,” adds Vice President of Sales & Marketing Mike Leakey. “Conversely, if auxiliary axles are not deployed when needed, the vehicle may not comply with local bridge laws, and the vehicle and its occupants may even be exposed to dangerous mechanical forces.”

“With the ROI Auxiliary Suspension System, fleets will be able to get new drivers trained and working in less time,” he contends. “Exceeding axle ratings can be dangerous as well as costly due to unscheduled maintenance and fines. Now even novice drivers can avoid these issues, maintaining safety and efficiency.”

ROI Auxiliary Suspensions suit mixers, dumps, bulk tanker-grade regional haul tractors, plus heavy-duty tractors running in on- and off-highway conditions. With field testing in progress, 8K, 10K, 13.5K and 20K ROI Auxiliary Suspension systems are scheduled for 2022 delivery. The series was announced at the Technology Maintenance Council 2021 Fall Meeting & Transportation Technology Exhibition in Cleveland, Ohio.

An initial aftermarket product launch will see Link design a Bodybuilder Package with control system integrated into the suspension. The manufacturer’s Swift Mount technology, coupled with the package, will give upfitters and bodybuilders the ability to install intelligent auxiliary axles in less time than traditional auxiliary suspensions. Link developed its smart load-balancing suspensions using the proprietary ROI technology, which premiered with the 2019 introduction of the Cabmate Cab Suspension. —Link Mfg., Sioux Center, Iowa; 800/222-6283; www.linkmfg.com/dealers