A venture between the LafargeHolcim U.S. Cement business and Solidia Technologies will supply EP Henry’s Wrightstown, N.J., block & paver plant with a reduced carbon dioxide binder plus companion curing equipment. The proprietary production method’s formal launch stems from a six-year effort by the three companies to bring to commercial scale a technology that reduces embodied CO2 in manufactured concrete by up to 70 percent versus conventional, portland cement-based production methods. Development has centered on Solidia Cement milled at the Lafarge Whitehall plant in western Pennsylvania, along with aggregate materials Solidia Technologies sources separately.

Read MoreDay: September 28, 2019

Oldcastle APG shores up Pacific NW footprint with Abbotsford Concrete

The acquisition of British Columbia-based Abbotsford Concrete Products will expand Atlanta-based Oldcastle APG’s hardscape unit offerings and manufacturing capabilities in its western Canada region. Founded in 1989 by Clifford Leach, Abbotsford Concrete has established itself as a hardscapes leader under the direction of sons Chris and Bob Leach. The producer has strong dealer relationships, exceptional quality assurance, innovative engineering, and a proven operational focus, Oldcastle APG affirms. In addition to a market-leading hardscapes brand, the deal brings two top tier paver, slab and segmental retaining wall production facilities.

Read MoreConcrete pipe: Unquestionably best for drainage construction

The American Concrete Pipe Association’s new video, linked to YouTube from www.concretepipe.org, presents precast, rigid concrete pipe as the ideal choice for durable drainage installations. In every region across North America, engineers, the association contends, transportation departments and contractors know they can trust concrete pipe as the most resilient choice to last for over 100 years. The video explores benefits and performance characteristics backing up that confidence:

Read MoreSika, celebrity architect BIG team on 3D printing demonstration

The parent of Sika Corp. is partnering with one of the world’s top architects, Bjarke Ingels Group (BIG), to showcase 3D concrete printing capabilities at the “Formgiving” Exhibition at the Danish Architecture Center in Copenhagen, Denmark. Running through January 2020 in the architect’s home base, the exhibition focuses on the future of construction and how it shapes the planet.

Read MoreCorps, Marines team cites 3D concrete printing first in high volume demo

Marine Corps Systems Command and 7th Engineer Support Battalion staff joined U.S. Army Corps of Engineers Construction Engineering Research Laboratory (CERL) colleagues last month to test a 3D concrete printing operation with a late model volumetric mixer feeding a 3-in. nozzle. The Champaign, Ill., demonstration was staged to fabricate a field-grade bunker, and followed Marine Corps units’ barrack and bridge structure printing with a 2-in. nozzle assembly.

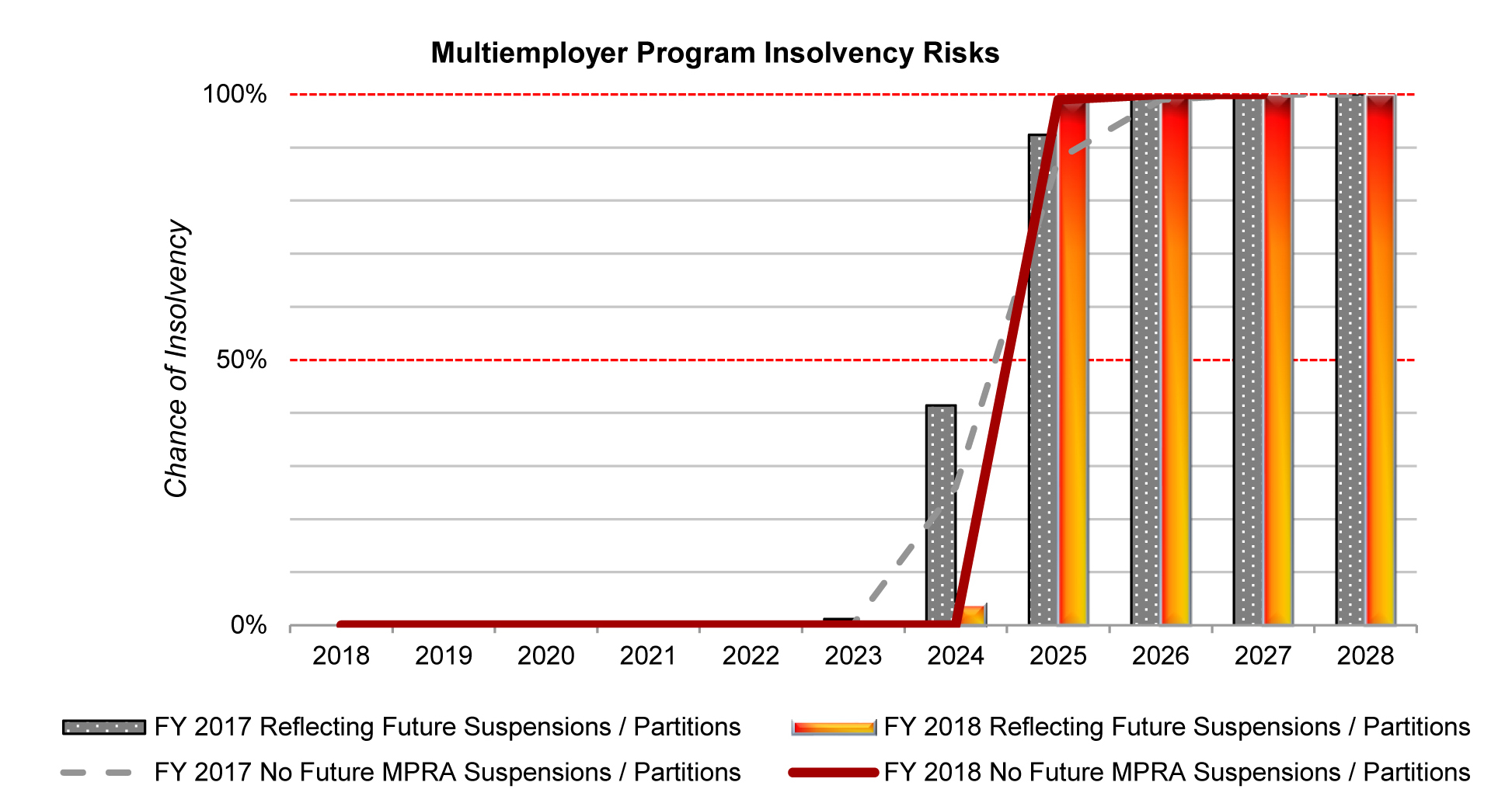

Read MoreMultiemployer pension backstop plan advances on Capitol Hill

From the Associated Builders & Contractors, Washington, D.C. … The U.S. House of Representatives has passed the Rehabilitation for Multiemployer Pensions Act (H.R. 397), with 29 Republicans joining the majority in a 264-169 vote. Advocates argue the measure is needed to protect the pensions of 1.3 million workers in certain multiemployer pension plans (MEPP)—up to half of which cover construction trades participants—and prevent a Pension Benefit Guaranty Corporation (PBGC) collapse.

Read MoreTax reform a principal catalyst behind $100M precast plant venture

Fortified Precast Technologies, LLC has outlined an ambitious Florida residential real estate development plan, leveraging a partnership with German precast concrete production specialist Vollert Group and Opportunity Zone provisions in the Tax Cuts & Jobs Act of 2017 (TCJA). The company’s Fortified Precast Opportunity Fund is authorized to raise $100 million in $20 million increments to build five plants incorporating Vollert mix delivery, form pallet and companion robotics or casting components. At 32,720 sq. ft. of daily wall panel output, each operation would be capable of supplying more than 4,200 home projects annually. The capacity would be initially targeted to the Sunshine State market, which has seen residential building permits climb from 116,200 in 2016, to 122,700 in 2017 and 142,300 last year.

Read MoreASCE opens Infrastructure Report Card to stormwater chapter

Water Environment Federation (WEF) salutes the American Society of Civil Engineers and its Environmental & Water Resources Institute (EWRI) for adding a stormwater chapter to the 2021 Infrastructure Report Card—the first time drainage structures and facilities will be graded in a widely subscribed benchmark the Society issues every four years. The category will join Aviation, Dams, Inland Waterways, Ports, Rail, Schools, Solid Waste, Hazardous Waste, Bridges, Roads, Drinking Water, Levees and Public Parks chapters.

Read MoreResearchers gauge green infrastructure’s capacity for high runoff

University of Maryland, College Park, researchers are approaching urban and suburban stormwater management with the ultimate goal of increasing resiliency to major weather events. With models predicting more rain than historical levels, plus an increased frequency of particularly intense and destructive storms, they note, flooding is a major concern in communities that are becoming more settled.

Read MoreEPA determination spares admixtures, coloring agents from SPCC regulation

After more than three years of the Environmental Protection Agency soliciting expert advice and public comment on issuing a proposed rulemaking potentially expanding the petroleum product spill prevention, control and countermeasure (SPCC) terms typical of concrete plant environmental permits, Administrator Andrew Wheeler has signed a final action establishing no new regulatory requirements under the Clean Water Act (CWA).

Read More