Branscome Concrete, Essroc Cement prove the economy of $30,000/yd. concrete in radiation shielding.

By Don Marsh

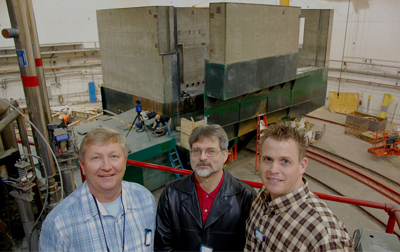

| Perched on a Hall C equipment platform overlooking the new SHMS shield house are (from left) Branscome Concrete’s Jack Kowalski, Hall C Senior Engineer Bert Metzger, and Essroc Cement’s Jeremy Betts. PHOTO: Jefferson Lab |

An area of concrete practice synonymous with mass structures and pricey materials is going on a diet and budget plan at the U.S. Department of Energy’s Jefferson National Accelerator Facility (JLab).

After lengthy mix development, production and placement trials, practitioners at the Newport News, Va., facility have revealed radiation shielding technology with wall and roof members a) of streamlined cross section compared to prior methods deployed in atomic particle beam and nuclear energy environments; and, b) fabricated from concretes bearing optimized levels of expensive chemical compounds uniquely suited to containing subatomic particles. Central to the technology are Type II portland cement mixes using two grades of aggregate: One an inexpensive, recycled manufacturing byproduct; the other priced as if it were sourced through DeBeers and fittingly dubbed “Black Diamond.”

Success of the mixes and their meticulous production and placement will be measured in the ability of an enclosure—combining cast-in-place wall and precast roof panel construction—to contain wayward subatomic particles that jeopardize human health and computer software’s binary sequences. The wall and roof members comprise the shield house for the Super High Momentum Spectrometer (SHMS) under construction at JLab Experimental Hall C, where radiation is generated from electron beam–nucleus collisions.

Williamsburg, Va.-based Branscome Concrete secured an unusual contract calling for development of a mix laden with boron carbide (B4C), a $10/lb. compound long associated with radiation shielding on its own or as ultra fine aggregate within a concrete matrix; and, a lightweight mix whose recycled-polypropylene aggregate, coupled with expanded shale, could sustain elevated hydrogen levels critical to curtailing radiation.

Astronomical B4C costs compelled Branscome staff to approach trial mixes with economy of small scale. “We started with a Hobart mixer to determine the feasibility of a mix design well over 50 percent boron carbide powder, which has particle characteristics like portland cement and is similarly milled,” says Branscome’s Jack Kowalski, Specialty Products & Quality Assurance. “The mix was for a 9-inch wall as envisioned by physicists not structural engineers, and the boron carbide was chosen for one of three levels of subatomic particle shielding. Initial tests suggested the mix design would require a superplasticizer dosed at 300 ounces per 100 weight of Type II portland cement. Our admixture supplier had doubts.”

|

| PHOTOS: Jefferson Lab (formwork); Concrete Products (pour). |

Branscome teamed with Essroc Cement Corp. for over three years to formulate viable shield house concrete mixes, JLab officials budgeting a 20-week construction window within a schedule of much other activity (note Black Diamond, pages 42-43). Testing in the ready mix and cement producers’ Williamsburg and Martinsburg, Va., labs netted a design for what is surely some of the most expensive concrete to date. Mix performance hinged on maintaining lab physicists’ boron carbide content target, 88 lbs/cu. ft., but easing the superplastizer quantity with a goal of reasonable set time (< 36 hours). An extended set time for the final B4C mix design promoted particle packing—bleed water rising as fines settled and densified the matrix.

Branscome and Essroc conferred with UK Abrasives Inc., which processes and markets Ukraine-sourced boron carbide in 4- to 125-micron gradations. Using a blend of particle sizes plus Boral Material Technologies’ ultrafine Micron3 high performance pozzolan, they demonstrated a concrete whose B4C content suggested a 5-in. thick wall versus the specified 9-in. profile—netting a material savings in the $250,000 range based on the boron carbide concrete layer’s critical, but limited role in the SHMS shield house.

“As the principal aggregate, the boron compound imparts a charcoal coloring to the finished product. Beyond the shielding factor, the B4C concrete has density, weight and compressive strength comparable to conventional material,” says Essroc Senior Manager, Technical Services Jeremy Betts. “The final mix consisted of varying boron carbide gradations, which achieved the necessary particle packing; a Sika polycarboxylate superplasticizer; our Type II cement; and the Micron3.”

|

| Approaching the final shield house concrete phase, Hylton Builders crews prepare precast door and roof panel forms. The shield house and experimental equipment bear on a rail-guided, steel box frame. Hall C’s lifting equipment easily handled the bucket transfer of boron carbide concrete (2-cu.-ft. pour shown above), produced within the shield house footprint atop the box frame; and, lightweight aggregate (expanded shale, recycled polypropylene scrap) mixes, dispatched from Branscome Concrete’s Williamsburg headquarters plant. |

“Jefferson Lab calculations confirmed the potential for the thinner profile we proposed, but staff opted for 6-in. thick boron carbide concrete layer,” adds Essroc Cement Territory Manager Marie Derby, based at the company’s Newport News terminal. “With a delivered cost of nearly $30,000 per yd., we wouldn’t be surprised if the boron carbide mix represents one of the most expensive, yet practical concretes in the world considering the money owners saved with the finished structure.”

Six inches of B4C concrete forms an inner layer along two sides of the shield house, the front wall measuring 25 ft. long x 14 ft. high. Integral reinforcement joins the layer to a larger concrete wall section anchoring the structure. Varying from 24 to 35-in. thickness, it consists of the specialized lightweight concrete, with aggregate limited to expanded shale and recycled polypropylene. The lightweight concrete also forms a 20-in. thick center partition separating subatomic particle detection equipment and electronics for recording particle activity following electron beam-nucleus impacts. Rounding out the shield house wall system are one of two assemblies instrumental in radiation containment: a 2-in. lead layer with ¼-in. aluminum plate on both faces; or, a ¾-in. thick, resin-bound boron carbide composite.

Approaching the final shield house concrete phase, Hylton Builders crews prepare precast door and roof panel forms. The shield house and experimental equipment bear on a rail-guided, steel box frame. Hall C’s lifting equipment easily handled the bucket transfer of boron carbide concrete (2-cu.-ft. pour shown above), produced within the shield house footprint atop the box frame; and, lightweight aggregate (expanded shale, recycled polypropylene scrap) mixes, dispatched from Branscome Concrete’s Williamsburg headquarters plant.

|

| PHOTOS: Concrete Products |

Black Diamond

Northbrook, Ill.-based UK Abrasives describes one of its main powder products, boron carbide, as a high performance abrasive material with chemical and physical properties similar to diamonds. Darker than silica fume and, like cement clinker, well suited to grinding, boron carbide exhibits hardness characteristics second only to diamond and boron nitride, earning the nickname “Black Diamond.”

Boron is an important material for nuclear applications due to its high neutron absorption cross section, UK Abrasives notes. In addition, it doesn’t contain decay products with a long half-life and high-energy secondary radioactive materials. Since pure boron is extremely brittle and difficult to produce in shapes, boron carbide is the material of choice in radiation shielding as it provides a high concentration of boron atoms and is relatively easy to fabricate.

Jefferson Laboratory officials estimate that boron carbide represents more than one-third of the $1 million budget for structural components in the Experimental Hall C Super High Magnetic Spectrometer (SHMS) construction. Traditional mix designs for radiation shielding would have required more than double the 17.5 tons of boron carbide powder used in the product Branscome Concrete and Essroc Cement formulated for parts of the SHMS shield house.

A decision to have the B4C mixes produced on site netted material savings upwards of $100,000 compared to mixer truck delivery. “When you finish pouring from a 9-yd. mixer load, there can still be a yard of material left in the drum,” explains JLab Hall C Engineer Paul Brindza, who oversaw testing and approval of the Branscome and Essroc mixtures. “When you get done pouring, there’s still a yard left. So, cleaning the truck out costs you $30,000. Using half a dozen trucks, a lot of money gets dumped on the ground … Using small batches and mixer in the hall, we lost very little material.”

In formulating the shield house concrete mix designs, “We needed to not just optimize the shielding, but the process of making and placing its concrete. We did a lot of engineering to make a product that anybody could dump into place and form up,” he adds, noting that the B4C and lightweight concrete mix combination has applications in structures for compact nuclear reactors, radioactive-waste storage, plus diagnostic or medical treatment applications where radiation is generated.

|

| UK Abrasives delivered various grades of boron carbide powder in 700-lb. or larger supersacks, staged with conventionally packaged Essroc Type I/II powder on the main work floor of Hall C. Branscome Concrete crews prepared the boron carbide mixes in small batches, using an 1/8-yd. electric mixer on a work platform 14 feet above the floor level. |

Approaching the SHMS shield house planning, Brindza and Hall C Senior Design Engineer Bert Metzger tasked Branscome Concrete with creating a mix design maximizing boron carbide content while still attaining a minimum 3,000-psi compressive strength. Mix research and development commenced in February 2010 with 50 lbs. of boron carbide JLab secured through UK Abrasives.

“We started with mixes having 1:1 and 1:3 ratios by volume of cementitious material to B4C,” recalls Branscome Concrete’s Jack Kowalski. “Using what would be considered a normal amount of water, the fineness of the Type II portland cement and boron carbide powder drove a dosage of 300 ounces per hundred weight of cement of Sika Viscocrete 2100 polycarboxylate. Sika typically recommends a dosage rate of 6–12 ounces per 100 lbs. of cementitious material to produce self-consolidating concrete.

“Both the 1:1 and 1:3 cementitious material/B4C ratio mixes were very thixotropic and could be produced on a larger scale, but discharging them from a transit mixer could prove difficult without adding an undetermined amount of water and compromising the design compressive strength.”

Branscome and Essroc staff ran a second series of mix designs with 1:1, 1:3, 1:4.5 and 1:6 cementitious material/B4C ratios, plus high range water reducer and viscosity modifier. “We thought in terms of a mix that would meet the strength requirement, and that could be produced at the batch plant, delivered in mixer trucks and pumped into the forms,” says Kowalski. “Even with all of the changes made, the designs were not sufficient enough to meet the desired characteristics, and were discarded. This was kind of like trying to make concrete out of #57 and #67 stone without any sand.”

the initial attempts at a B4C mix design, Branscome and Essroc explored other options with JLab staff, weighing the use of larger, but still nuclear-grade boron carbide particles. Continuing with a Type II portland cement, testing began on two new mixes with different B4C particle sizes to maximize packing; Boral Material Technologies Micron3 ultra fine fly ash; and, new admixtures. The results were encouraging and indicated the potential for 90 lbs. of boron carbide powder per cubic foot of concrete mix—10 lbs. over Hall C engineers’ target.

the initial attempts at a B4C mix design, Branscome and Essroc explored other options with JLab staff, weighing the use of larger, but still nuclear-grade boron carbide particles. Continuing with a Type II portland cement, testing began on two new mixes with different B4C particle sizes to maximize packing; Boral Material Technologies Micron3 ultra fine fly ash; and, new admixtures. The results were encouraging and indicated the potential for 90 lbs. of boron carbide powder per cubic foot of concrete mix—10 lbs. over Hall C engineers’ target.

“One challenge for us and the contractor was mix set time,” notes Essroc’s Jeremy Betts. “Because we still had to run 100 oz./cwt of the superplasticizer—down by two-thirds from original test mix dosage—set times were higher than normal, about 48 to 60 hours. This had a positive effect on the mix, because the slower than normal set time allowed for mix subsidence, therefore densifying the finished product.

“Late one day while testing, we cast four beams for flexural testing and observed potential problems due to mixes’ fluidity and materials’ fineness: Two of four beam molds had less than a millimeter gap between the bottom plates and sides. By the next day, the small gap had yielded approximately 10 lbs. of mix, which had started to harden on the floor around the beam. We stressed to the contractor the importance of crews lining plywood forms with plastic sheeting, to prevent loss of moisture, and building a form equal to a mix with such consistency.”

After finalizing a workable B4C mix design aimed at concrete with shielding and no load-bearing function, Betts and Kowalski pursued a mix design for the SHMS shield house structural walls. “Because of the size and weight restrictions inside Hall C, we needed to develop a lighter weight concrete using expanded shale aggregate,” Kowalski explains. “In addition to the weight requirements, questions arose as to how to maximize and retain as much hydrogen in the concrete mixture as possible for the life of the structure. Water lost in cement hydration also meant loss of hydrogen in the finished concrete.

|

| Hall C Lead Engineer Paul Brindza, who lead the SHMS shield house design, engineering and specifications, brandishes boron carbide (left) and lightweight aggregate concrete specimens. JLab operator Jefferson Science Associates is licensing the mix designs within a broader radiation shielding technology for electron beam and nuclear energy applications. |

“Bentonite, crumb rubber, and polypropylene fibers or scrap were among substitute aggregate possibilities considered. Polypropylene ended up being the best solution, because it is widely used in concrete as fiber, and bears high amounts of hydrogen. We saw equal performance from different types of plastic—extruded pellet and recycled scrap. Seeing no benefit using the more expensive extruded plastic, we went with the recycled product.”

Lightweight mix development began in October 2012 at the Branscome lab. “We had an idea of how much portland cement, fly ash, Boral Micron3 pozzolan, and expanded shale aggregate was needed to obtain the desired compressive strength,” says Kowalski. “We ran mixes increasing the percentage of recycled plastic while removing the same volume of lightweight aggregate. Increasing the plastic aggregate in 5 percent increments consistently decreased compressive strength by about 15 percent. A mix design with 20 percent recycled polypropylene aggregate, or about 300 lbs./yd., was chosen.”

The B4C and lightweight aggregate mixes were developed for Jefferson Science Associates, LLC a private entity that operates JLab under Department of Energy contract. The lab owns the intellectual property associated with the concrete mixes and the concept of B4C and lightweight aggregate concrete wall layers, coupled with lead and resin-bound, boron carbide composite layers, as a radiation shielding technology. Like other JLab breakthroughs, the concrete mixes and shielding concept are subject to a three-step technology transfer process: engage inventors, review for patentability and marketability, and license intellectual property.

The boron-rich concrete technology, “Thermal neutron shield and method of manufacture,” has been granted patent #8,450,707 by the U.S. Patent and Trademark Office; companion technologies, “Lightweight Concrete with Enhanced Neutron Shielding” and “Cost Effective Boron Shielding Panels” are patent-pending. The latter references the resin-bound B4C composite supplied by a local countertop fabricator. All three technologies are available for licensing through Jefferson Science Associates.

UK Abrasives delivered various grades of boron carbide powder in 700-lb. or larger supersacks, staged with conventionally packaged Essroc Type I/II powder on the main work floor of Hall C. Branscome Concrete crews prepared the boron carbide mixes in small batches, using an 1/8-yd. electric mixer on a work platform 14 feet above the floor level.

|

| Super High Momentum Spectrometer-bound electron beams will terminate at detection equipment to be fitted in the left half of the shield house. The right half is built for electronics programmed to record electron-nucleus collisions, plus ensuing neutron and proton behavior and travel. JLab staff liken the electron beam and particle scattering sequence to the breaking of a pool rack. Recording and analyzing of post-collision neutron and proton behavior is central to JLab research. Hall C engineers designed the shield house wall and roof sections according to projected particle travel and confinement needs—a cross section of the most robust wall profile shown here. |

PARTICULAR PHYSICISTS

The shield house side and partition walls are cast in place. Branscome crews have pre-cast seven rectangular roof panels, plus three doors, staging forms for the 20-in. thick, B4C concrete members in the main Experimental Hall C work area. A circular structure with 150-ft. diameter, 60-ft. dome-like ceiling, Hall C is home to a charter High Momentum Spectrometer (HMS) whose research capabilities will be bested with SHMS. The latter is part of a $338 million upgrade centered on JLab’s workhorse, the 7/8-mile long Continuous Electron Beam Accelerator Facility (CEBAF).

The Branscome and Essroc team’s optimized wall profile and roof panel cross sections offer cost and weight savings: The shield house and experimental equipment bear on a steel box frame travelling a short arc along a 2,000-ton load capacity rail. Work area limitations in the testing and measuring equipment-cramped facility—coupled with the costly boron carbide powder—shaped the contract’s call for Branscome crews to produce and place mixes in plywood formwork for another shield house contractor, Hylton Builders of Virginia Beach.

Prepared in a 1/8-yd. electric mixer, the B4C concrete averages a 32-in. spread on self-consolidating test measurements and, with cake batter consistency, a tendency to ooze into any form void—owing to the uniformly fine particle distribution of boron carbide, Type II cement and Micron3 agent. “Pumping it would have wasted too much material, as the lowest point of placement is 14 feet in the air,” explains Jack Kowalski, noting that the shield house base had a work area for the mixer plus eight-member and three-member production and placing crews, respectively. Typical pours entailed just over 2 cu. ft. of B4C mix per hour, conveyed short distances in an overhead crane-mounted, ½-yd. bucket. Branscome delivered the significantly lower cost, lightweight wall mixes in 8-yd. loads from its Lee Hall plant in Williamsburg. As the producer closed out work early this year, the shield house concrete schedule stood at 275 yd. of lightweight and 10-yd. of B4C mixes.

JLab physicists specified the concrete layers to moderate or attenuate subatomic particles that generate radiation, primarily certain grades of neutrons. The lightweight concrete’s elevated hydrogen content—attributable to the recycled plastic’s grade of polypropylene, plus matrix moisture level—thermalizes radiation-yielding neutrons and converts them to gas. Boron in the B4C mix layer absorbs low energy neutrons, while the lead blocks photons, another grade of neutral subatomic particles.

“Ordinary concrete could slow down, or thermalize, neutrons, but would require a very thick layer in the Hall C equipment. In concrete, the neutrons are thermalized when they strike hydrogen atoms in the water molecules that are trapped during the mixing process,” says Lead SHMS Engineer Paul Brindza, who charged Branscome and Essroc with developing a lightweight mix rich in the element topping the periodic table. “To keep the elevated hydrogen level permanent, we used shredded, plastic molding waste. Plastic is mostly hydrogen and carbon, with a little bit of chlorine. The lightweight aggregate mix looks and pours like ordinary concrete but has four times the capability to thermalize neutrons, and is two thirds the weight of ordinary material with the same compressive strength.”

Once neutrons are thermalized, he continues, “You’re only halfway toward the goal of eliminating them. While a neutron is bound up inside a nucleus with protons, it can remain indefinitely. Should a neutron be freed of the nucleus by the CEBAF electron beam, as often happens in Jefferson Lab experiments, it can drift around for another 15 minutes before falling apart into less-harmful particles.”

“Neutrons become like the gas in the room,” adds Hall C Senior Design Engineer Bert Metzger. “They go with the air conditioning. If you open the door, they come out. They’ll go under the door. They’ll come through a pipe. They go further, because they’re not charged. And everywhere they go, they can wreak havoc on experimental equipment and electronics.

“In modern electronics, the structures in the memory chips are very tiny and sensitive to single event damage—meaning a single particle can change a one to a zero. Eventually, these changes add up and software recording particle collision activity ceases to function. Then, the only way to fix the problem is to attempt a reboot so the software can be reloaded. If that doesn’t work, then memory cards must be replaced at a cost of around $100 each. While that’s an inexpensive fix, getting to that point is costly. Rebooting Hall C systems takes about an hour on average—meaning about $50,000 in CEBAF running costs.”

|

| The Continuous Electron Beam Accelerator Facility is a 7/8-mile loop of electron beam conduits (bottom); dubbed cryomodules, they accelerate electron travel to nearly the speed of light. Certain beams are directed to Experimental Hall C, home to the charter High Momentum Spectrometer and new Super High Momentum Spectrometer, a side view of which is shown here along with the shield house’s panel-clad elevation. Built of high performance concrete walls, plus lead, aluminum and boron carbide composite layers, the shield house contains a particle collision detector (below) and other specialized equipment. |

A BILLION ELECTRONS HERE AND THERE

Branscome Concrete supplied material for Hall C’s HMS shield house in the mid-1990s. Through a monolithic concrete wall, cast with a boron carbide and glass aggregate-dosed mixes, it contains radiation generated by one of the facility’s principal procedures: Smashing of electron beams into hydrogen, carbon or gold targets; collecting and recording information on scattered particles; and, analyzing particle speed, direction and energy with an eye toward improved understanding of an atom’s nucleus.

The new shield house is necessarily bigger and better; its construction marks the midpoint of the JLab upgrade, which between 2009 (construction start) and 2017 will see a doubling of CEBAF energy, from 6 billion electron volts (6 GeV). The SHMS will afford greater measurement of particle behavior attending the 12 GeV beams, while its new shield house separates particle detection from computer-based data collection equipment.

The elevated voltage for the SHMS in turn requires higher performance shield house concrete. Armed with 15 years of particle behavior data in HMS experiments, Hall C and Catholic University of America physicists turned to Monte Carlo statistical sampling methods to determine likely SHMS radiation parameters dictating shield house wall and roof system requirements.

In contrast to atom splitting associated with nuclear energy, the CEBAF sends electrons into a target nucleus to scatter individual protons and neutrons, plus smaller, paired particles called quarks. The accelerator works like a microscope, JLab notes, but uses electrons to reveal details too small for light to resolve. Lab officials put their target matter in perspective: A piece of aluminum foil is 250,000 atoms thick, quarks at least 1 millionth their size.

Powerful electron microscopes enable viewing of atoms; smaller particles are not seen but their behavior is observed in the type of detection and collection equipment used in JLab Hall C. A CEBAF beam of electrons into a target nucleus nets vast amounts of data, from which scientists look for patterns. The accelerator has to channel billions of electrons at enormous speed in order to hit one nucleus in the target.

CEBAF comprises an elongated loop of electron beam conduits called cryomodules. They are cooled to within a few degrees of absolute zero (approaching -460°F), and accelerate the electrons from a standing start to nearly the speed of light. Electrons are injected into a strand the diameter of human hair, their travel and paths augmented by massive magnets. After clearing five miles in 30 millionths of a second, electron beams are routed to detector assemblies in Experimental Halls C, B, A or D.

Starting in 2016, the upgraded electron beam and Hall C equipment will carry JLab into a new phase of discovery, as scientists seek greater understanding of nucleus and physics’ Standard Model, describing fundamental particles and their interactions. JLab officials credit the electron with dominating 20th century technology and scientific revolutions. The quarks they can observe through lab upgrades have the potential to be the 21st century’s electrons.