The Hyperion volumetric scanning system is built from a network of fixed-position LIDAR (light detection and ranging) units mounted around a designated yard or stockpile area for fast and accurate sand, gravel and crushed stone volume calculation.

The devices do not require manned operation and are not subject to the limiting factors of drone flight or photogrammetry, like pilot availability, or issues with image-conversion errors (shadows or night-time capture). Scanned pile data generate instantaneous point-clouds on demand or schedule, which are quickly calculated into volumes using a specifically designed surface-mapping algorithm to provide near real-time data. The fully automated process takes only a couple of minutes to complete.

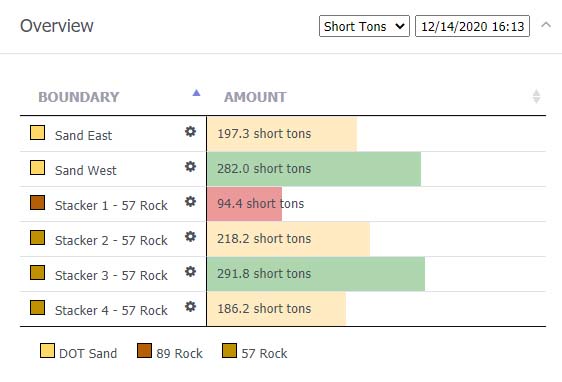

The user interface is designed for mobile or desktop access with a focus on legibility and ease of use. Programmers have simplified the Hyperion software to first display current aggregate volume and tonnage, then proceed to more granular elements and actual 3D representations as needed. The monitoring system has been tested and proved for over a year and shown accurate to +/-1 percent. Hyperion is scalable in that it can be used for anything from relatively small batch plant piles covered by a single unit or scaled up to much larger operations by combining data from multiple scanners. — Altamus Inc., Gainesville, Fla., 352/283-8003; www.altamusinc.com; Koogler and Associates, Inc., Gainesville, 352/377-5822 x19; www.kooglerassociates.com