Solidia Technologies has teamed with start-up Uncountable to build a data analysis platform expediting research & development and commercial application surrounding the former company’s low carbon cement and concrete. Using data science, machine learning and artificial intelligence, Uncountable’s web platform equips Solidia and its customers to improve production and finished elements or structures by trialing myriad concrete formulations without years of experimentation. It serves as a bridge between the company’s Piscataway, N.J. headquarters lab and optimization at customer facilities during pilot and commercial phases.

Chemical-intensive processes where the Uncountable platform has been deployed include rubber, a material whose formulation, temperature phases and engineering property index have direct parallels to concrete. The platform can speed analysis and manipulation of data generated during the mixing, placing and carbon dioxide-based curing of Solidia concrete—enabling users to cut development time, reduce testing iterations and identify enhanced production methods plus mix designs faster than present practice.

“Because our chemistry is simple, we can model, measure and predict the manufacturing process, and quantify performance and impact improvements,” says Solidia CEO Tom Schuler. The company is working with Uncountable to expedite evaluation of the broad space of chemistries available for concrete formulations, he adds, contending, “Never before has the industry had eyes inside the curing chamber or a means of rapid-fire testing that can expedite production upgrades and efficiencies, new recipes, and improved performance in concrete. We’re spearheading the data revolution in cement and concrete, bringing sustainable solutions and process optimization faster to a global industry.”

“[Our] tools accelerate development of the most robust process for Solidia Concrete,” affirms Uncountable Founder Noel Hollingsworth, who leads a team of Massachusetts Institute of Technology and Stanford University engineering graduates. “Powered by AI algorithms, our platform mitigates the need for tedious, manual tweaking of individual ingredients. Complicated development processes that would involve tens or hundreds of experiments are now conducted by Solidia in half the time utilizing advanced machine learning models.”

| EXPLORE DATA |

|

|

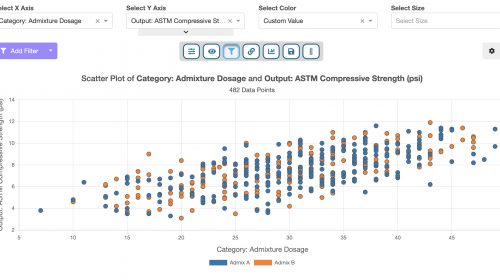

| Default scatter plot view in the Uncountable platform Explore Data module. By demonstrating that Admix A and Admix B have similar mechanical performance, Solidia can confidently switch to more cost-effective Admix B with minimal risk of adverse effects. |

| COMPARE FORMULATION |

|

| Historical data, assumptions, and constraints provided by Solidia allow Uncountable to tweak its machine learning models to recommend the minimum amount of experiments needed to thoroughly test the concrete mix design space. Uncountable’s model reduces required number of experiments by 50 percent compared to traditional design of experiment methods while maintaining accuracy. |

| VIEW CORRELATIONS |

|

| Through the Uncountable platform’s Correlation Matrix, Solidia is able to efficiently and effectively evaluate the relationships between individual factors to multiple response variables at a time. The correlation coefficient values range from -1.00 and +1.00, with +1.00 meaning the value of response increases as the value of the factor increases. This tool allows Solidia to focus on factors that serve as key input variables to its curing process. |