Amid strong market conditions, cement, aggregate and concrete producers face logistics challenges ranging from unpredictable supply chain disruptions and driver shortages to new sustainability mandates for reducing carbon emissions in product transport and common variants. The latter include narrow delivery time windows, ad-hoc orders, and last minute cancellations. Then there is the matter of manual or spreadsheet-based planning processes, which are time-consuming, burdensome, error-prone, and often conducted in silos thereby hindering efficient communications and collaboration in transport planning and related resource management.

Unlike manual processes or legacy programs, Inform artificial intelligence-powered Transport Planning and Execution optimization software for building materials addresses the primary challenges producers and distributors face while delivering key benefits. The program provides digital torque enabling dispatchers and planners to perform very complex, time-critical calculations with ease. Applying the software, they are able to move more payloads with fewer trucks each day.

Added to a company’s existing information technology landscape (i.e., enterprise resource planning system, telematics, tracking applications, customer portals), Transport Planning and Execution serves as a central tool for dispatchers and customer service teams, delivering these principal features and functions:

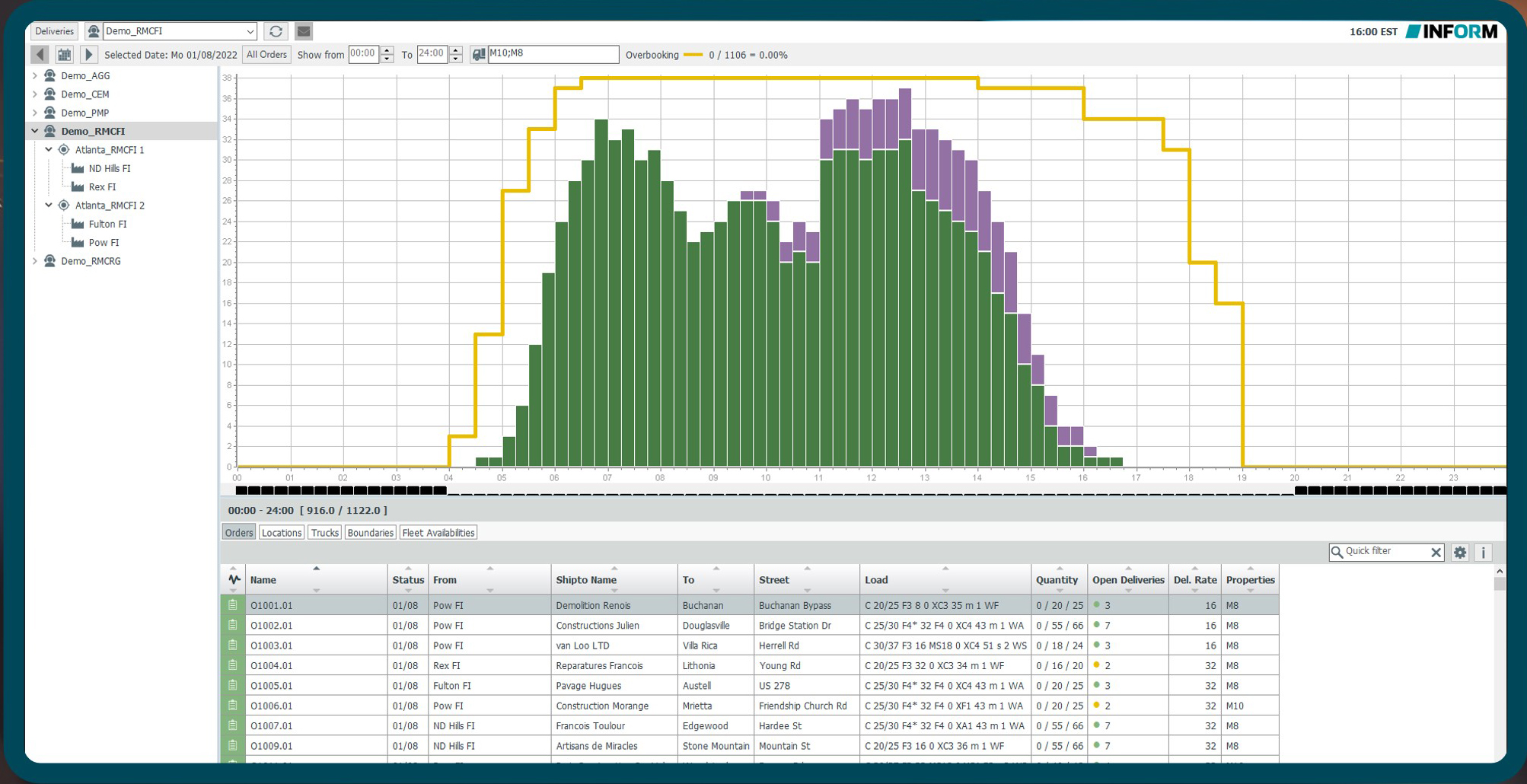

- Tactical planning. The software calculates an optimized delivery schedule and fleet configuration for the next day, incorporating the service levels selected by dispatchers, who can also compare several scenarios with just the push of a button.

- Real-time optimization. The impact of order changes, cancellations, delays, truck or equipment breakdowns is significantly reduced as the software automatically updates schedules every minute to enable these problems to be addressed.

- Availability-to-promise. The software’s consolidated real-time view of orders and transport capacity enables producers’ customer service teams to identify time slots at the point of order taking that best suit the customer’s requirements, as well as the producer’s needs.

- Strategic planning. The program optimizes fleet sizing or redistribution, truck right-sizing, fleet mix, and hauler contracts. Key performance indicators of the system accelerate strategic planning processes dramatically. Further, Inform on-demand strategic planning services and simulation studies afford customers significant operating cost savings potential.

ARTIFICIAL INTELLIGENCE

Artificial intelligence algorithms serve as the base layer for Inform users in ready mixed concrete, cement and aggregates. They deliver the right mix between cost control and service levels for material deliveries. Applying the algorithms, producers can achieve short, optimized, and sustainable routes in support of low carbon dioxide emission logistics. AI algorithms have proven to outperform standard spreadsheets and legacy systems both in speed and quality.

AI-powered Transport Planning and Execution Software users can expect to realize such benefits as lower logistics unit costs; higher customer service levels; up to 30 percent more loads per truck per day; emissions reduction; increased situational awareness and real-time decision making for dispatchers; and, business-line specific optimizers all integrated into one central tool. — Inform Software Corp., Norcross, Ga., 404/333-0233; www.inform-software.com

MARCOTTE SYSTEMS COLLABORATION

Inform Software Corp. and Marcotte Systems, developer of information technology tools supporting ready mixed concrete production and delivery, have announced a collaboration centered on artificial intelligence-powered dispatch solutions. By combining the latter company’s experience in concrete production management with Inform’s AI capabilities, the ready-to-use solution will empower users with enhanced decision-making tools, real-time optimization, and intelligent automation—ultimately elevating operational performance and customer satisfaction.

“This marks a significant milestone in our commitment to advancing ready mix dispatch through the power of AI,” says Inform Logistics Division Senior Vice President Thomas Bergmans. “In addition to offering our proven AI-powered Transport Planning and Execution software, I’m very excited to see that this collaboration will further speed up the widespread use of our AI algorithms beyond traditional markets.”

“We are confident that the synergy will redefine industry standards, providing our clients with a competitive edge in an ever-evolving market,” adds Marcotte CEO Joel Bardier. “The integration of AI into ready mix dispatch processes will streamline operations and open new possibilities for innovation.”