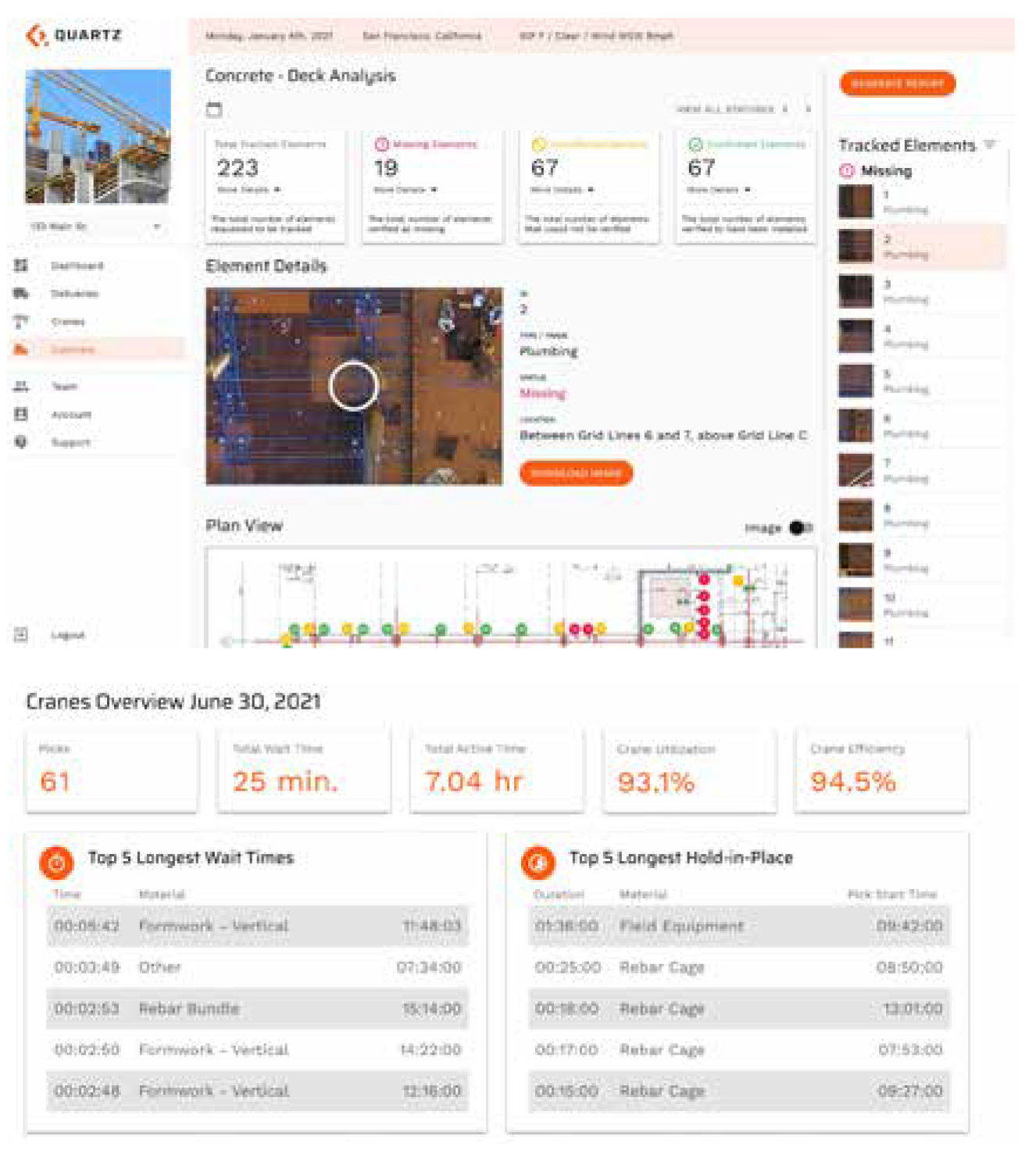

Construction technology services provider Quartz Systems demonstrated the quality control and productivity-gauging potential of its new Concrete Deck Analysis program at World of Concrete 2021. The integrated hardware and software platform uses ultra-high resolution 4K video streams, machine learning, plus a web and mobile app to enable project principals to understand everything happening on a construction site. Users can see live and historical views from anywhere; track ready mixed or precast concrete, rebar and other deliveries down to the second; measure crane, equipment and tool use; observe crew output; and, monitor site security.

Using feeds from 4K video cameras typically mounted on a crane hook, boom tip and drum or counterweight, Concrete Deck Analysis allows project managers to quickly confirm placed mechanical, plumbing or reinforcing elements—at high accuracy (< 1 inch) levels—and identify missing or misplaced ones ahead of a pour. “The latest advancements in hardware and image processing allow us to provide element verification at higher resolution than ever before,” affirms Quartz Co-Founder and Head of Product Conor Lenahan. “We are working steadily towards dimensional verification. Eventually, this will eliminate the need for drones in vertical construction and reduce or replace expensive laser scanning.”

Developed with leading general contractors, Concrete Deck Analysis incorporates existing plans, schedules and drawings for baseline reference. Image streams and software analytics yield a detailed Deck Verification Overview report, documenting present and missing elements. Form and pour team members can log in to a dashboard to securely view and quickly address any issues prior to mixer truck arrival.

“Our easy-to-use tool focuses on three areas: progress, productivity, and prediction,” says Quartz Co-Founder and CEO Jeremy Conrad. “Quartz enables customers to track and understand their progress, improve site productivity, and, when necessary, predict impacts to schedule or budget based on their workflows. To date, our customers have been able to track work progress in 4K with Quartz Site Vision.”

Tracking progress is a core function of managing daily activities on any site, he adds. As part of select pilots across the country, Quartz is rolling out the first generation of automated tracking, affording project managers daily updates on work performance compared to planned schedules. The Quartz platform will soon be able to ingest site schedules and use photogrammetry data to provide status updates, including identification of progress on specific tasks by zone of the working deck. Future updates include advanced productivity tracking as well as scheduling and budget projections. — Quartz Systems, San Francisco, www.quartz.co

NEW TAKES ON MATERIAL DELIVERIES

Ahead of the Concrete Deck Analysis launch in Las Vegas, Quartz Systems built a deep visual library, samples from which show activities at representative multi-story building sites in Florida and California: Loading Dock camera informing crane operator of arriving mixer trucks to charge hook-mounted bucket; Jib Tip camera to receive blind picks from a rebar trailer and record ready mixed deliveries; and, a Hook Camera deployed to safely remove the slick line from the self-climbing concrete pumping boom. The Quartz Delivery Tracking tool is documenting each arrival and departure by truck type, trade and material.