Occupying the site of a hotel that hosted guests from Pope John Paul II and Ronald Reagan to John F. Kennedy and U.S. Chief Justice Earl Warren, the Wilshire Grand Center is rising on sound footing thanks to a Guinness Book of World Records-grade concrete placement.

Catalina Pacific Concrete delivered 2,120 loads of ready mixed over a 19-hour, mid-February window for the 73-story hotel’s mat foundation. The flagship concrete business of Glendora Calif.-based CalPortland Co. mustered 208 mixer trucks and 235 drivers across five of its own and three A&A Ready Mixed Concrete plants, four to 20 miles from the downtown Los Angeles site. Executed without a single injury, the operation marked what project officials note is a new volume threshold for a continuous foundation pour: 21,200 yd., slightly besting a 1999 record set for The Venetian, Las

Vegas.

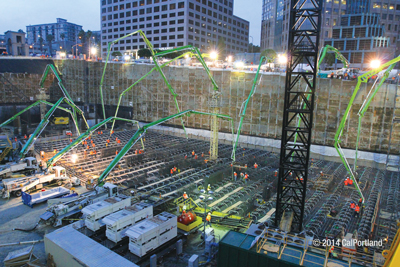

“A typical sequenced pour on a similar project would occur over weeks. With a continuous pour, we saved time, and because we poured at once, rather than in segments, we were able to create an incredibly strong foundation for this iconic tower,” says Scott Borland, vice president in the Los Angeles office of general contractor Turner Construction. Concrete contractor Conco Cos. staged 13 of its pumps—from a total of 19 machines on site—to place mixes for a 17.5- to 18-ft. thick mat as far as 100 feet below grade. The foundation mix is designed with a 25 percent fly ash binder and required to meet 6,000 psi compressive strength at 90 days. Headwaters Resources shipped Catalina Pacific 1,800 tons of fly ash from its Pomona, Calif., terminal. In addition to aggregates from its Los Angeles County sites, CalPortland supplied the Catalina Pacific and A&A plants more than 5,000 tons of Type II cement from its Colton and Mojave, Calif., mills.

|

| Gauging the heat of hydration in a concrete mat at least 18 feet—even with a 25 percent fly ash binder component—engineers specified plastic piping to circulate chilled water through the mass concrete supporting the new Wilshire Grand Center. |

The Wilshire Grand main pour and subsequent concrete deliveries netted a mat up to 20-ft. thick, partly reflecting the high seismic factor accompanying a southern California high-rise building. It tested CalPortland’s raw material and ready mixed production and delivery capabilities, the latter measured partly on truck scheduling and routing success. Catalina Pacific’s fleet runs on the Android-based GeoTrax mobile fleet management platform of TruckTrax, a Vancouver, Wash., technology provider in which CalPortland is a partner.

“GeoTrax played two important roles in the overall success of the Wilshire Grand foundation pour. We were controlling dispatch from the job site, and GeoTrax was able to give us an ‘electronic bird’s eye view’ of what was happening at the job site and remote plants,” says Catalina Pacific Dispatch Manager Bryan Power.

“It provided ticketing data so we could properly track the overall production at the multiple batch plants servicing the pour. “The use of the GeoTrax tablets by the drivers allowed us to track individual trucks as needed and provide location data for dispatching and ticketing purposes. GeoTrax provides notification to Clearview /TruckTrax that a specific truck has broken the ‘Electronic Fence’ at the ready mixed plant and is available to be dispatched. That information includes the truck identification number and eliminates the need for the dispatcher to manually enter the information when vehicles arrive.”

Catalina Pacific will deploy the GeoTrax technology throughout the Wilshire Grand Center contract, which over a 2014-2016 schedule requires upwards of 100,000 yards for the steel framed tower’s cast-in-place core and composite floor slabs. Designed by Los Angeles’ AC Martin Partners, the $1 billion, 1,100-ft. property will mark a new height record for a U.S. building west of the Mississippi. Developer Korean Air, which acquired the original facility in 1989, then operating as the Los Angeles Hilton & Tower, is targeting a 2017 Wilshire Grand Center opening.

GUINNESS RECORD, NRMCA RECOGNITION

|

|

|

| The University of Southern California marching band ushered the Catalina Pacific fleet to the pour. A USC alumnus, Catalina Pacific Vice President and General Manager Melanie O’Regan observed the procession from the lead mixer. |

As the final yard set more than 2,100 loads later, she assembled with project officials and Guinness World Records adjudicator Michael Empric (third from left), who confirmed the new concrete placement milestone. Joining them are (from left) Turner Construction’s Scott Borland; Conco’s Rick Parker; Turner’s Mike Machesano; Conco’s Jesse Cook; and, Catalina Pacific’s Charles Kerzic. |

Two weeks after the Wilshire Grand Center mat foundation pour, O’Regan joined colleagues in Las Vegas at the annual convention of the National Ready Mixed Concrete Association, which presented a Special Recognition Award honoring the job’s success. |