David Chevalier owns seven ready mixed plants, operating under Béton Chevalier inc., the Stoneham, Quebec-based flagship business, or as Béton Royal. His fleet of 70 mixer trucks covers a 150-mile radius of metropolitan areas and rural communities in central and eastern Quebec.

Meeting tight client specs and delivery schedules, especially in the demanding Northeastern weather and traffic patterns, is a perpetual challenge. Batching or dispatching issues can quickly play havoc with a bottom line under constant competitive pressure. Having readily experienced the positive impact of technological innovations on the productivity and profitability of his various plants over time, Chevalier was keen to look into how he could harness the power of cloud computing to scale up his operational efficiency as suggested by Mathieu Leclerc, founder of Globe Technologie, his IT services supplier.

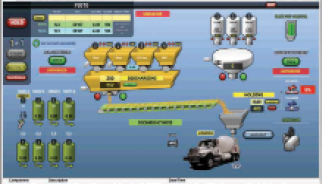

Cloud computing and the recent development of the Software as a Service (SaaS) business model held an enticing potential in terms of greater mobility and flexibility. In the fall of 2015, Chevalier started using Marcotte on Demand, a new delivery platform for the Marcotte Systems field-tested software supporting his various plants. He hasn’t looked back since: Wherever he finds himself and whenever the need, Chevalier, or any vetted member of his team, can control any portion of the batching process at any of the company’s plants from any computer station or mobile device. He can as easily control dispatching and monitor key management markers from his truck, hotel room or home. Optimal client satisfaction is thus always at his, and his team’s, fingertips.

CASH FLOW, ROI IMPACT

A key advantage of Marcotte on Demand is that Béton Chevalier and Béton Royal pay only for what services are currently needed. The producer enjoys an unlimited user and truck licensing mode, plus an interface with GPS and accounting systems, and is charged merely for the number of plants from which trucks are dispatched. Furthermore, no capital investment is required; access to the software is through a monthly subscription, there is no need for additional hardware infrastructure or for dedicated IT staff. The operational efficiencies can thus immediately improve the producer’s bottom line.

“For a number of months now, my clients have experienced first-hand the benefits of my using the power of the cloud to deliver the right product at the right time at a most competitive price,” Chevalier affirms. “This improves the overall value chain and proves that, as ready mixed operators, we can indeed propel the construction industry forward through our commitment to hard work and innovation.”

Béton Chevalier inc. and sister operation Béton Royal serve markets from central Quebec to the eastern part of the province, including Sherbrooke, home to the plant shown here.