Cemex, S.A.B. de C.V. has announced a proprietary technology, dubbed “Spider Tracker,” that monitors concrete during placing and hardening to measure strength development in real-time. It enables contractors to remove formwork at precisely the right moment and make informed decisions about the concrete specified for their jobs. Such actions can result in time and cost savings and potentially a reduction…

Read MoreTag: portland cement

National Cement doubles flagship mill capacity, calms CO2 emissions factor

Executives of National Cement Company of Alabama Inc., parent National Cement Company Inc., and ultimate parent Vicat Group, Paris, staged a late-July dedication of a new production line at their Ragland, Ala. plant. A Kiln 2 ribbon cutting capped a two-year, $300 million project that brings annual Ragland capacity above 2 million short tons and assures a sharp reduction in…

Read MoreBreakthrough Binder

Investors targeting reduction of the carbon dioxide emissions factor in portland cement and concrete have focused on methods capturing, using or storing the greenhouse gas, plus new means of generating the high temperatures fossil fuel-fired cement kilns need to convert limestone and other raw feeds to clinker. A Longmont, Colo. startup has garnered backing for technology paving a different path…

Read MoreInvestors commit nearly $50M to SCM, Blended-CM developer Terra CO2

Sources: Terra CO2 Technology, Golden, Colo.; CP staff A just-closed $46 million Series A funding round will support commercial scale production and further market development of Terra CO2 Technology’s OPUS SCM (Supplementary Cementitious Material) and BCM (Blended-Cementitious Material) brands, which offer alternatives to Class F fly ash (10-40 percent dosage rate), as regional market conditions warrant, and low-carbon substitutes (≤…

Read MoreEco Material balances SCM portfolio with natural pozzolan mine venture

Sources: Eco Material Technologies, South Jordan, Utah; CP staff Arizona customers and public officials joined Eco Material for a June 21 ribbon cutting at the Kirkland Pozzolan Mine, located in hilly, desert terrain 75 miles northwest of Phoenix. CEO Grant Quasha credited construction and mining teams, as well as plant equipment suppliers, with creating a world class facility—one advancing the…

Read MoreCemex concentrates solar heat for calcining, clinker production first

Sources: Cemex S.A.B. de C.V., Monterrey, Mexico; CP staff In a joint project at the Very High Concentration Solar Tower of Spain’s IMDEA Energy, Cemex and Swiss sustainable fuels specialist Synhelion report processing of the world’s first “solar clinker.” Research and development teams set up a pilot batch production unit to weigh and transfer limestone, clay and other raw feeds…

Read MoreHolcim (US) mill goes full bore on portland limestone cement

A Texas concrete materials supply chain fixture, the Holcim (US) Inc. Midlothian plant is the first cement mill in the country to fully convert to production of portland limestone cement (PLC), where fine limestone at 5 percent to 15 percent volumes is ground with clinker. The finished binder exhibits performance comparable to ordinary portland cement, but has a lower embodied…

Read MoreCement developer Hoffmann lands U.S. patent for alkaline powder

After nearly three years of examination, the United States Patent Office has validated the Hoffman Green Cement Technologies H-EVA patent (US 2021/0179492 A1). Promoted as an alternative to portland cement for ready mixed concrete, mortars and plaster, H-EVA encompasses flashed clay sludge, natural or synthetic (flue gas desulphurization) gypsum, plus proprietary chemical “activators and superactivators.” The mineral processing and chemistry…

Read MoreLow carbon LC3 binder steers Sika’s next admixture chapter

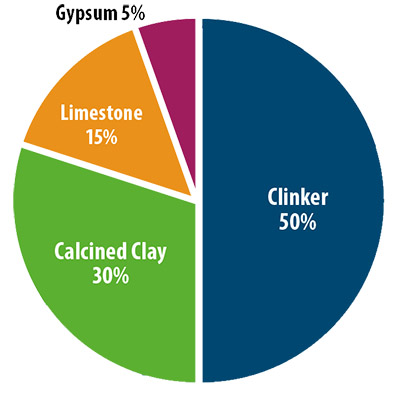

The Swiss parent company of New Jersey-based Sika Corp. will tailor a new family of concrete admixtures and cement additives around the chemistry and behavior of an emerging binder known as LC3, or Limestone Calcined Clay Cement. Through work with Sika AG and peers, Swiss Federal Institute of Technology officials view the material as a means of carbon footprint reduction…

Read MoreLehigh Redding moves to mill SCM from CO2-rich kiln emissions

Lehigh Hanson Inc. and Fortera Inc., a Silicon Valley technology developer wise to calcium carbonate chemistry and mineralization, are teaming to commercialize a process with optimal output for an era of greenhouse gas scrutiny: Converting the carbon dioxide gas emitted to the environment at the front end, or calcining phase, of ASTM C150 powder production into a blendable supplementary cementitious…

Read More