Sources: Pikus 3D, LLC, Salt Lake City; CP staff A key player of commercial construction-grade 3D concrete printing technology reports significant investments from top practitioners Baker Concrete Inc. and Lithko Contracting LLC, based respectively in Monroe and West Chester, Ohio.

Read MoreTag: 3D printing

Sika ramps up support for premier 3D printing system adopter

Source: Sika Corp., Lyndhurst, N.J. Sika Executive Vice President – Concrete & Waterproofing Kyle Loyd has added two members to the 3D Concrete Printing team he leads: Marketing Coordinator Lyndsay Castle, managing sales and support activities, and Process Engineer Noah Callantine, overseeing field service and program improvements. Most immediately, they will assist West Jordan, Utah-based Pikus3D LLC, the first adopter…

Read MoreCivil Engineering program offers 3D printing technology primer

Sources: Ohio University, Athens, Ohio; CP staff The Ohio University Russ College of Engineering and Technology presents concrete methods in “3D Printed Buildings Guide: Required Materials, Tips, and Resources” as part of a Master of Science in Civil Engineering degree overview, posted here. The guide provides an overview of 3D-printed buildings; project scheduling and labor-saving advantages; challenges for adoption of the…

Read MoreICC-ES report update envisions multi-story, 3D-printed structural concrete

Sources: Black Buffalo 3D Corp., New York; CP staff Black Buffalo, a global provider of large scale, building-grade printers and proprietary cement-based ink, has worked with the International Code Council Evaluation Service to expand criteria in the ICC-ES AC509 – 3D Automated Construction Technology for 3D Concrete Walls report from single- to multi-story building.

Read MoreASTM C01/09 symposium to cover cement, concrete, 3D printing

Sources: ASTM International, West Conshocken, Pa.; CP staff ASTM Committees C01 on Cement and C09 on Concrete and Concrete Aggregates are sponsoring the virtual Symposium on Standards Development for Cement and Concrete for Use in Additive Construction, December 7-8. Using the WebEx platform, committee members will present potential 3D-printed mortar or concrete test methods that can be standardized through ASTM…

Read MoreQuikrete continues expansion into 3D printing with housing demos

On the heels of a cooperative research and development agreement with the U.S. Department of Energy’s Oak Ridge National Laboratory to design next-generation concrete mixes ideal for printable construction of large-scale structures or components, Atlanta-based Quikrete Companies is branching out further into the 3D-printing process with its latest partnership.

Read MoreConcrete printing specialist to keynote Building Sciences conference

Sources: National Institute of Building Sciences, Washington, D.C.; CP staff

The U.S. Department of Commerce’s National Institute of Building Sciences has replaced its planned Washington, D.C. conference this summer with Building Innovation 2020: Virtual Edition, billing the August 18-19 program as “a powerfully compact event, focusing on technology, workforce, resilience and Covid-19.”

Read MoreLafargeHolcim, GE unit team on 3D-printed wind turbine pedestals

Sources: LafargeHolcim Ltd., Zurich; CP staff

The latest target in a LafargeHolcim investigation of 3D-printed concrete elements or structures is a pedestal for a new class of turbines, 150-200 meters high, that have the potential to harness one-third or more energy than the shorter towers dotting wind farms the world over.

Read MoreSWEET SUCCESS

Gate Precast turns to 3D-printed forms for ‘sugar crystal’ façade

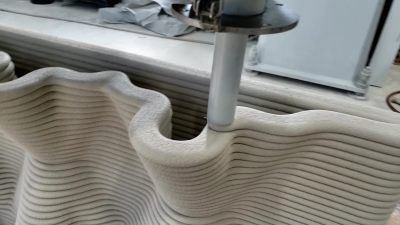

A towering mixed-use structure with a unique façade in Brooklyn’s Williamsburg neighborhood has not only changed the New York City skyline, but has shown the transformative possibilities of 3D-printed concrete formwork. Thanks to a collaboration with the U.S. Department of Energy’s (DOE) Oak Ridge National Laboratory in Tennessee, Jacksonville, Fla.-based Gate Precast Co. was able to bring the intricate design of One South First’s “sugar crystal” exterior to life as well as provide a major step forward for architectural precast.

Read MoreQuikrete extends 3D printing reach in housing unit demonstration

Source: Quikrete Companies, Atlanta

Quikrete and California-based Contour Crafting Corp. have entered into a collaboration to develop proprietary concrete used in the automated construction of residential, commercial, industrial and government structures using the latter’s technology. Following comprehensive testing at an independent accredited lab at the University of Southern California to confirm ICC-ES AC509 compliance—a building code spearheaded by CC Corp.—the 3D printing process will be used to construct four low-income housing units as part of a demonstration project sponsored by the Los Angeles County Development Authority.

Read More