Caterpillar has built a portfolio of tiered service offerings to help manage equipment assets and lower operating costs, whether the customer performs maintenance tasks or Cat dealer handles the details.

Read MoreAuthor: CP Staff

Round tube lift axle

The Toughlift platform is designed specifically to utilize round axles for non-steerable and steer applications in severe or heavy-duty conditions.

Read MoreConcrete form release agent

“Release” is a general-purpose concrete form agent of mineral oil and petroleum product composition. Its dual action formulation is lightly reactive with improved barrier characteristics.

Read MoreCoiled tool lanyards

Through a compact system that keeps lanyard length close to the anchoring point, the new Squids 3130 coiled model reduce snags and trip hazards.

Read MoreCustomized safety gear

A Web-based application (www.honeywellsafety.com/myhardhats) enables customers and distributors to fully customize hard hats from the complete Fibre-Metal and North brand offerings. In four steps, visitors can create their signature look by selecting a hat style, color, suspension and graphic. A customer service team supports the application by answering questions and fulfilling orders.

Read MoreConcrete, grout pump hoses

Abrasion-resistant and rated at 1,230 psi, the Marauder Concrete Pumping and Plaster & Grout models join company’s industrial hose series.

Read MorePortable washout containers augment environmental compliance at job sites

Joining the company’s mixer truck-mounted washout containers are the 0.5- and 1.5-yd. Porta-Pit vessels, plus companion Water Dog absorption bags. At 150 lb. (empty weight) with 44- x 42-in. footprint, the larger Porta-Pit features high-strength, cross linked polyethylene plastic construction with rugged steel fork lift channels and side supports.

Read MoreFormwork extends traditional block profile

Company has broadened the concept behind armor-type block units cast with 1-yd. of fresh concrete or returned mixes. Betonblock USA molds are made of high-strength, low-alloy steel and finished with a powder coating for long-term durability. They allow ready mixed and precast concrete producers to cast large, stackable block for stockpile divider and property walls, plus structural retaining walls.

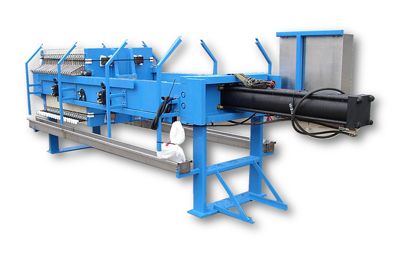

Read MoreFilter press line solidifies Enviro-Port reclaiming role

A filter press series from D.R. Sperry & Co. of Aurora, Ill., has joined Enviro-Port’s line of concrete reclaiming and slurry handling equipment. Filter presses enable producers to reduce settling pond sediment handling requirements and solids drying time, while also expediting the return of water for process and batch use.

Read MoreSilo maintenance method averts confined space entry

A central Illinois ready mixed concrete producer has resolved material build-up issues in three storage silos where accumulation had slowed production and increased internal pressures, eventually damaging the vessel walls and forcing a shutdown. By enlisting the Martin Engineering silo-cleaning crew, the Commercial Acres RMC facility, whic is owned by Stark Excavating, was able to have the vessels safely emptied and ready for repair in 10 working hours—without confined space entry.

Read More