Sources: Materials Processing Institute, Middlesbrough, U.K.; CMCM staff

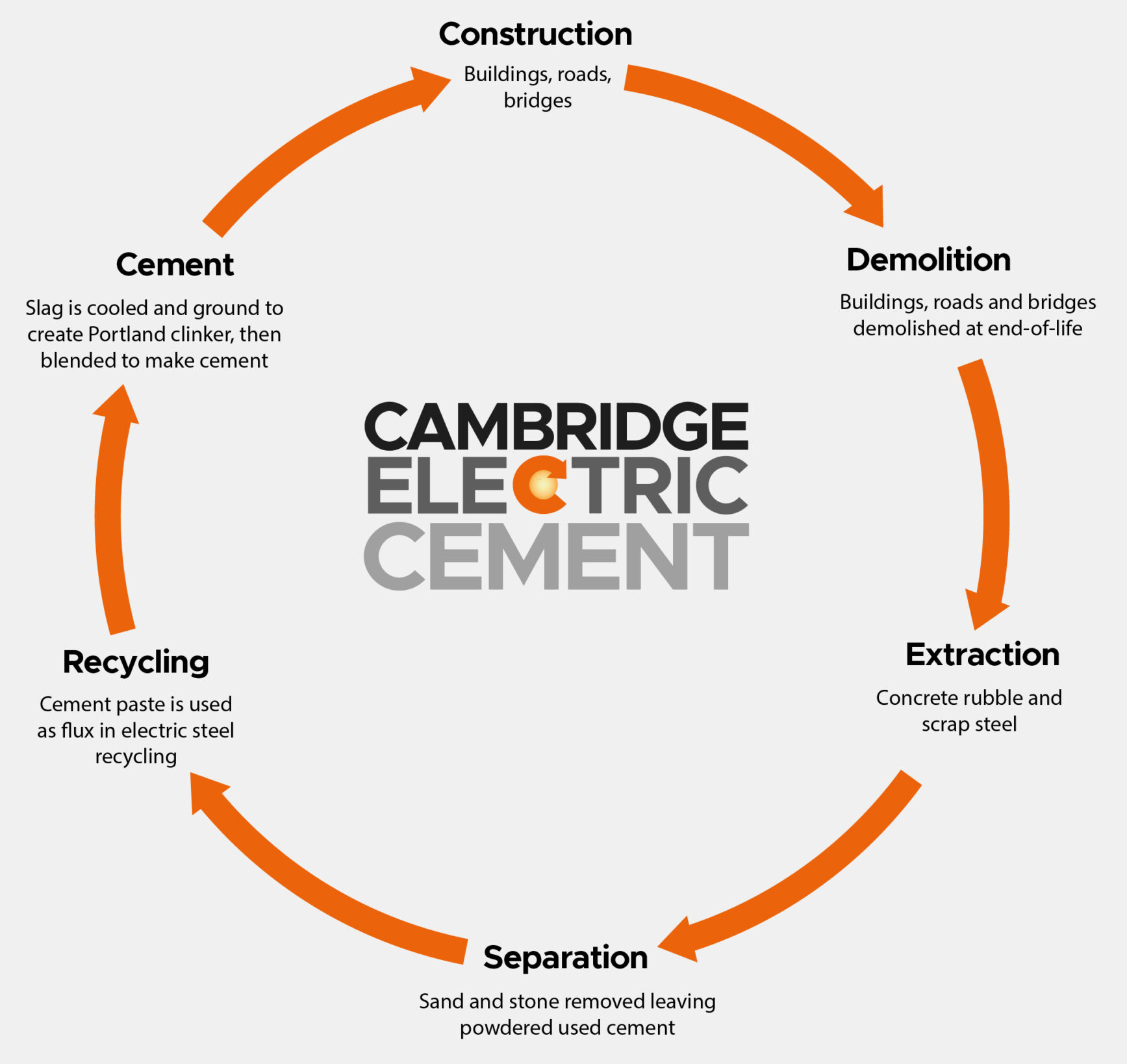

The United Kingdom’s Materials Processing Institute is testing the potential to transform finely graded cement paste, extracted from demolition concrete, to new cementitious material using scrap steel melted by an electric arc furnace. Dubbed Cement 2 Zero, the two-year project could prove at commercial scale the Cambridge Electric Cement (CEC) process developed at the country’s flagship university.

Cambridge researcher Dr. Cyrille Dunant pinpointed the chemistry at the heart of CEC, noting strong similarities between ground cement paste and lime-flux used in conventional steel recycling. As scrap melts, the flux forms a floating slag, protecting the liquid steel from ambient oxygen. Once the steel material is transferred, the liquid slag is rapidly cooled, ready for grinding to a powder with chemical and binding characteristics mirroring portland cement.

Assisting the Cement 2 Zero project with engineering, test equipment and field demonstrations are the U.K. offices of Atkins and Balfour Beatty; Celsa Steel, the country’s largest concrete reinforcing steel producer; plus aggregate and concrete producers Day Group Ltd. and Tarmac.

Related article

Steelmakers’ carbon emissions study template suits cement counterparts