Unilock, LPS Pavement, PICP underpin stormwater management upgrade

The Village of Kenilworth (Ill.) Public Works Department closed a 10-year stormwater management project in late 2022, signing off on nearly 84,000 square feet of permeable interlocking concrete pavement (PICP) from one of the Midwest’s best producer-installer tag teams: Unilock Chicago Inc. of Aurora, Ill. and LPS Pavement Co. of Oswego, Ill.

The two-phase undertaking for Kenilworth—the centerpiece of Chicago’s affluent North Shore—spanned six north-south streets where drainage limitations and the capacity of 1920s-era combined storm-sanitary sewer systems were evident during heavy rain events. One 2008 downpour left homeowners along the most impacted streets confronting 10-in. or deeper ponding at the base of their driveways.

Residents and village officials commenced planning sessions, engineering reviews and referenda measures aimed at storm sewer upgrades and a potential revision of a permit for runoff discharges to Lake Michigan, of which Kenilworth occupies about 0.8 mile of shoreline. A 2023 Kenilworth Infrastructure Improvement Program evolved from a 2012 referendum approving issuance of nearly $10 million in bonds. Its Green Infrastructure and Green Streets components, Kenilworth officials noted, spelled results that would:

- Benefit the environment, as permeable pavements help reduce contaminant levels naturally and restore natural ground water hydrology;

- Allow for smaller storm sewers while still improving stormwater management performance;

- Protect trees and improve drainage;

- Reduce energy consumption by lowering the amount of stormwater requiring Metropolitan Water Reclamation District treatment; and,

- Make use of today’s technology and knowledge to address long-standing Village problems.

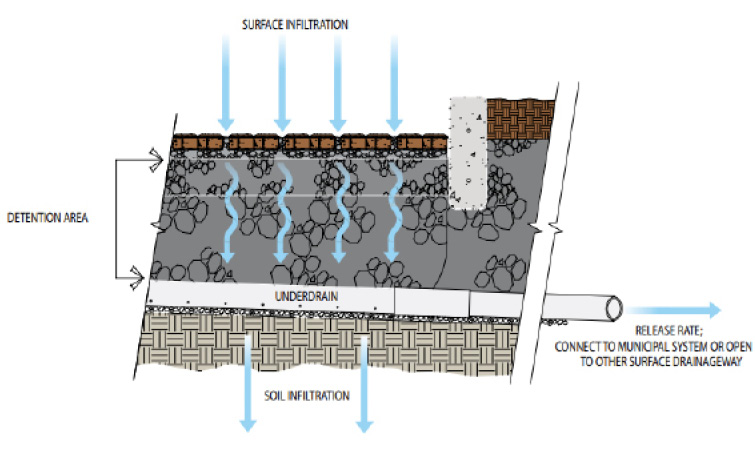

Green Streets Phase I was completed in 2017 and saw placement of permeable asphalt along three side streets. Kenilworth Public Works Department officials observed the pavements’ capacity to temper heavy rain event impact in tandem with the installation of a higher capacity storm sewer. Staff informed residents and village trustees that while the Phase I design had performed as promised, Green Streets Phase II warranted a more robust, longer service life specification. The result is Unilock Eco-Optiloc pavers on a subbase up to 24 in. deep, with bedding, base and subbase layers of 3/8-in., 3/4-in. and 2-in. stone placed on geotextile. Eco-Optiloc PICP installations along 1,300-ft. stretches of Leicester, Raleigh and Warwick Roads approach 84,000 square feet total.

Unilock presents the Eco-Optiloc pavers (26- x 26- x 8-cm) as capable of infiltrating up to 912 inches of rain per hour. Between the PICP and subbase, Kenilworth Public Works engineers estimate the new Warwick, Leicester and Raleigh pavement sections as capable of detaining more than 282,000 gallons during peak events.

Green Streets Phase II design and engineering abided guidelines of the ASCE/TD&I/ICPI 68-18 Permeable Interlocking Concrete Pavement standard. One of the benchmark projects informing the standard-authoring committee and Village of Kenilworth’s Phase II specification was Atlanta Department of Watershed Management’s 2014-15 installation of more than four miles of PICP streets in the Georgia capital city’s flood-prone Mechanicsville, Peoplestown and Summerhill neighborhoods.

Formula to Kenilworth Green Street success: Rolls of geotextile, truckloads of limestone, and layer upon layer of Eco-Optiloc permeable interlocking concrete pavers.