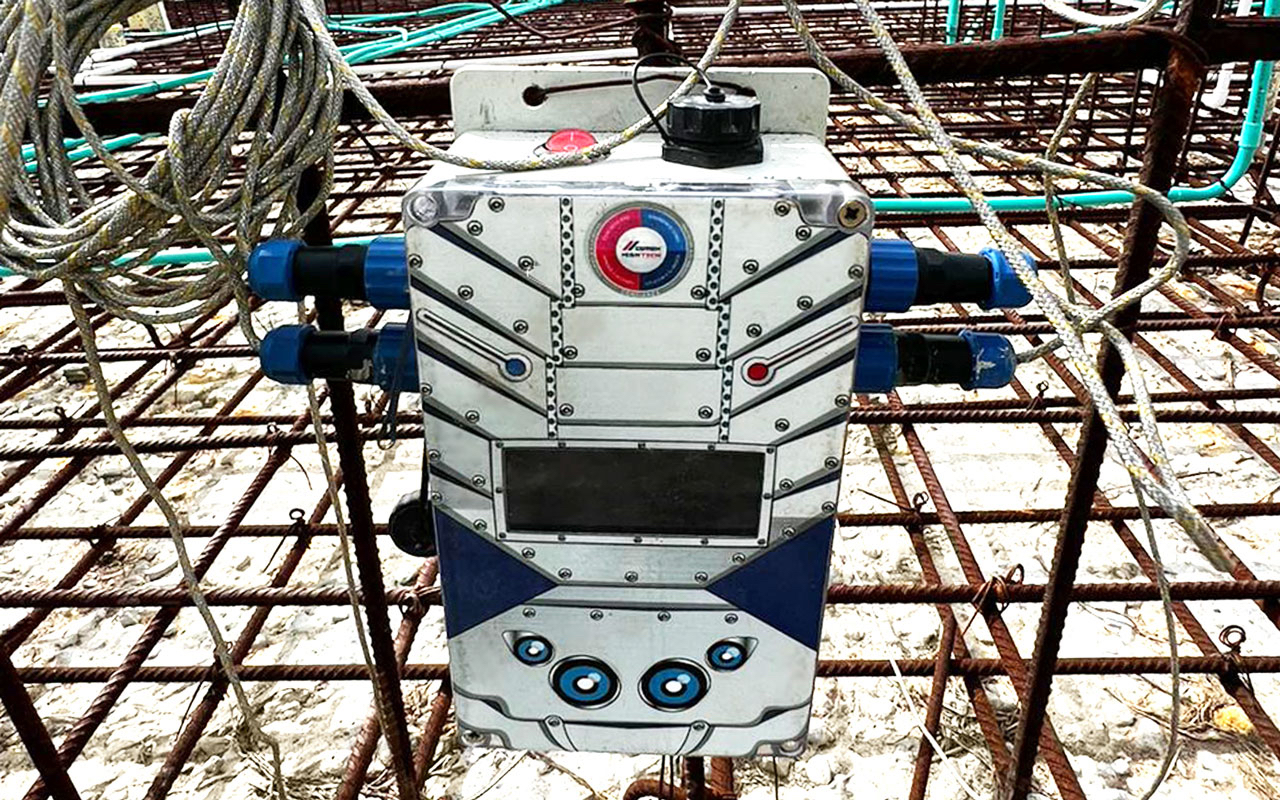

Cemex, S.A.B. de C.V. has announced a proprietary technology, dubbed “Spider Tracker,” that monitors concrete during placing and hardening to measure strength development in real-time. It enables contractors to remove formwork at precisely the right moment and make informed decisions about the concrete specified for their jobs.

Such actions can result in time and cost savings and potentially a reduction in the carbon footprint of a project because real-time information on strength development stands to reduce the volume of portland cement in a mix design. Through an optimized concrete composition, a specific jobsite like a tunnel or bridge can achieve a carbon dioxide emissions reduction exceeding 10 percent for a given design strength.

shown to reduce construction times by as much as 40 percent in real-world tests. The Cemex

technical team is currently scaling the platform geographies beyond South America pilots.

“Spider Tracker is a true innovation for the building materials industry and another way we are providing a superior customer experience by putting new technology at their reach,” says Cemex CEO Fernando González. “This latest achievement is further proof of our commitment to sustainability and the success of our Digital Innovation in Motion program.”

Spider Tracker’s sensors are placed in fresh concrete to measure its temperature at various points during the setting process. That information is relayed to thermo-tracking cylinders cast with the same concrete mix as the project and exposed to the same temperature through special containers. The cylinders recreate the hardening process at the same rate as the poured concrete, replicating resistance with more precision than other methods commonly available. By testing their resistance, contractors can determine when concrete in load-bearing members has reached its desired compressive strength.

Other real-time monitoring technologies for concrete are based on a mathematical predictive formula and, Cemex officials note, may be off by up to 80 percent in their estimation of actual compressive strength. Spider Tracker estimations prove on target by up to 95 percent, representing what product developers call “a game-changing innovation that gives the most accurate data available in the market.”

Spider Tracker uses a thermographic camera to place the sensors in the coldest points of the form. The technology also allows recording, controlling, and viewing of the entire process from a mobile application. Spider Tracker especially suits large-scale projects such as bridges and multi-story buildings requiring expensive formwork.