Sources: Concrete.ai, Los Angeles; CP staff

Mix design optimization specialist Concrete.ai has launched a beta version of its pioneering data science platform that reduces the cost and embodied carbon intensity (CO2e) in concrete construction. The new Software as a Service product debuted at AI DevWorld, a late-October conference in San Jose, Calif., and was selected as one of the top six artificial intelligence-driven technologies for the event’s Startup Alley.

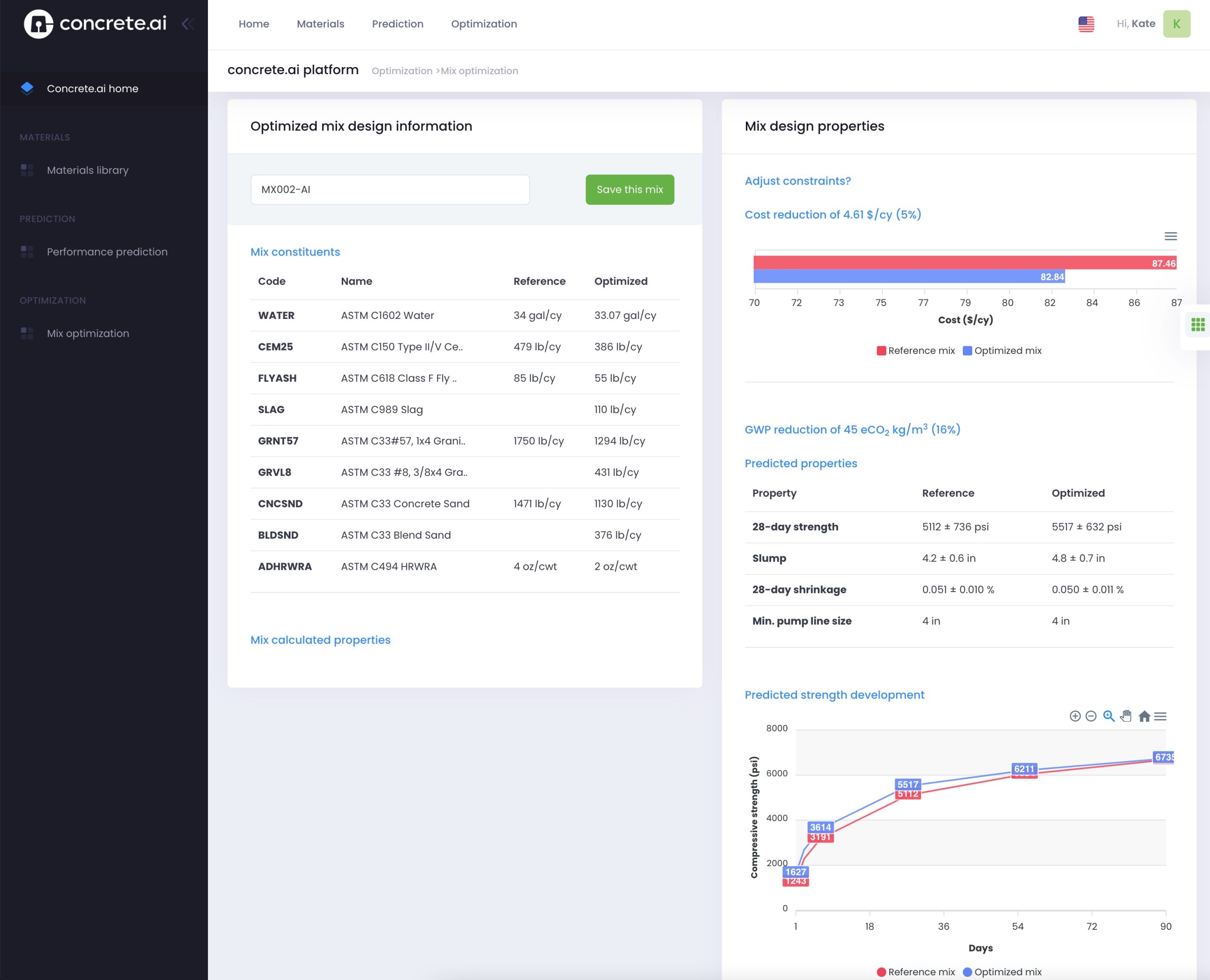

The Concrete.ai platform is promoted for attaining unparalleled reductions in the cost and CO2e of ready mixed and precast concrete. Applying AI to mix design and production yields “a highly optimized, cost-effective concrete that fulfills all engineering and performance characteristics, while utilizing locally available raw materials to ensure safety, longevity, and code-compliance.”

“Our platform leverages AI to increase both the speed and accuracy of concrete mixture design by converting what is usually a time-consuming ‘trial and error’ routine into a precise and efficient process,” says Concrete.ai CEO Alex Hall. “By merging what machines do best—extremely fast data processing—with the best of what experienced engineers and concrete professionals offer—human judgment—Concrete.ai has created a new pathway to safe, sustainable and lower-cost concrete construction by giving producers power over their data.”

In pre-commercial pilot testing with major producers, the company has verified that its technology reduces concrete material costs and CO2e by up to 12 percent and 70 percent, respectively. Tests have enabled Concrete.ai engineers to focus on algorithm refinement, as well as create a series of User Interface improvements designed to make it easier for concrete producers to run the platform. Concrete.ai is now conducting formal beta testing as the final step before commercialization.

Due to perennial difficulties in predicting how mix constituents will affect finished slab or structure performance, concrete formulations have been partially optimized and/or overdesigned and thus contain excess cement, Concrete.ai officials note. In the U.S. alone, they contend, this tendency costs the industry more than $2 billion-plus annually, and results in upwards of 10 million metric tons of incremental carbon dioxide emissions associated with cement production. If Concrete.ai models were adopted globally, annual carbon emissions from cement required for concrete production could potentially drop by 500 million metric tons.

Related article

Producers’ Choice