Sources: Euclid Chemical, Cleveland; CP staff

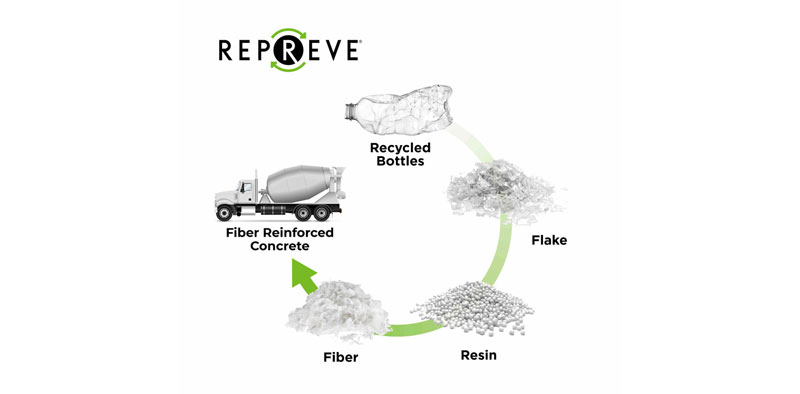

Euclid Chemical cites the sustainability benefits of its new PSI Fiberstrand Repreve 225 synthetic microfiber, a fine denier monofilament product bearing polyester material from post-consumer plastic bottles. The introduction stems from a partnership with Unifi, which has parlayed Repreve into the top branded fiber derived from recycled material.

Every pound of PSI Fiberstrand Repreve 225 diverts nearly 10 plastic bottles from landfills. Typically dosed at 0.5 lb./yd., the 1/4-in. long microfibers are designed to significantly reduce plastic shrinkage crack formation and spalling in concrete, as well as minimize segregation and bleed water. They also enhance surface durability, improving fire, impact and abrasion resistance. PSI Fiberstrand Repreve 225 suits concrete pavements, slabs-on-grade, overlays and toppings, wall systems, foundations, precast and prestressed structures, composite steel decks and decorative flatwork, plus shotcrete mixes. The product complies with ASTM C1116, Standard Specification for Fiber-Reinforced Concrete and D7508 Standard Specification for Polyolefin Chopped Strands for Use in Concrete, plus applicable portions of International Code Council Acceptance Criteria AC32 for synthetic fibers.