Concrete has been used as a strong, durable building material for thousands of years, dating back to ancient structures that are still standing to this day. Yet, it has one fundamental enemy it can’t escape—water. As an uptick in humidity and rainstorms wash across many regions throughout much of the calendar, water infiltration can lead to issues such as below-grade reinforcement corrosion, surface scaling, aggregate expansion, and mold growth.

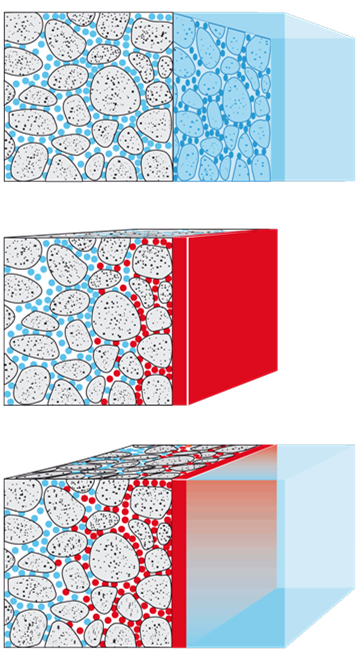

In order to provide sufficient workability for proper placement, compaction, mixing and transportation to the jobsite, most plant-batched concrete will contain excess water required to hydrate or chemically react with the cement. As concrete hardens, the water evaporates from the concrete and creates a network of fine capillaries and internal pores—essentially forming a “dense sponge” that allows water to transport through the surface, inviting damage as a result.

Here we examine three of the most innovative reactive technologies that concrete practitioners can use to combat water-related damage and ensure optimal slab or structure protection.

CRYSTALLINE WATERPROOFING

Crystalline waterproofing materials can be applied as a slurry coating to the surface of an existing concrete structure, such as a foundation wall or floor slab, as well as broadcast onto fresh horizontal concrete and troweled into the surface. An alternative approach involves adding the admixture directly into the concrete at the batch plant. In all cases, the waterproofing function includes both complex chemical and physical mechanisms.

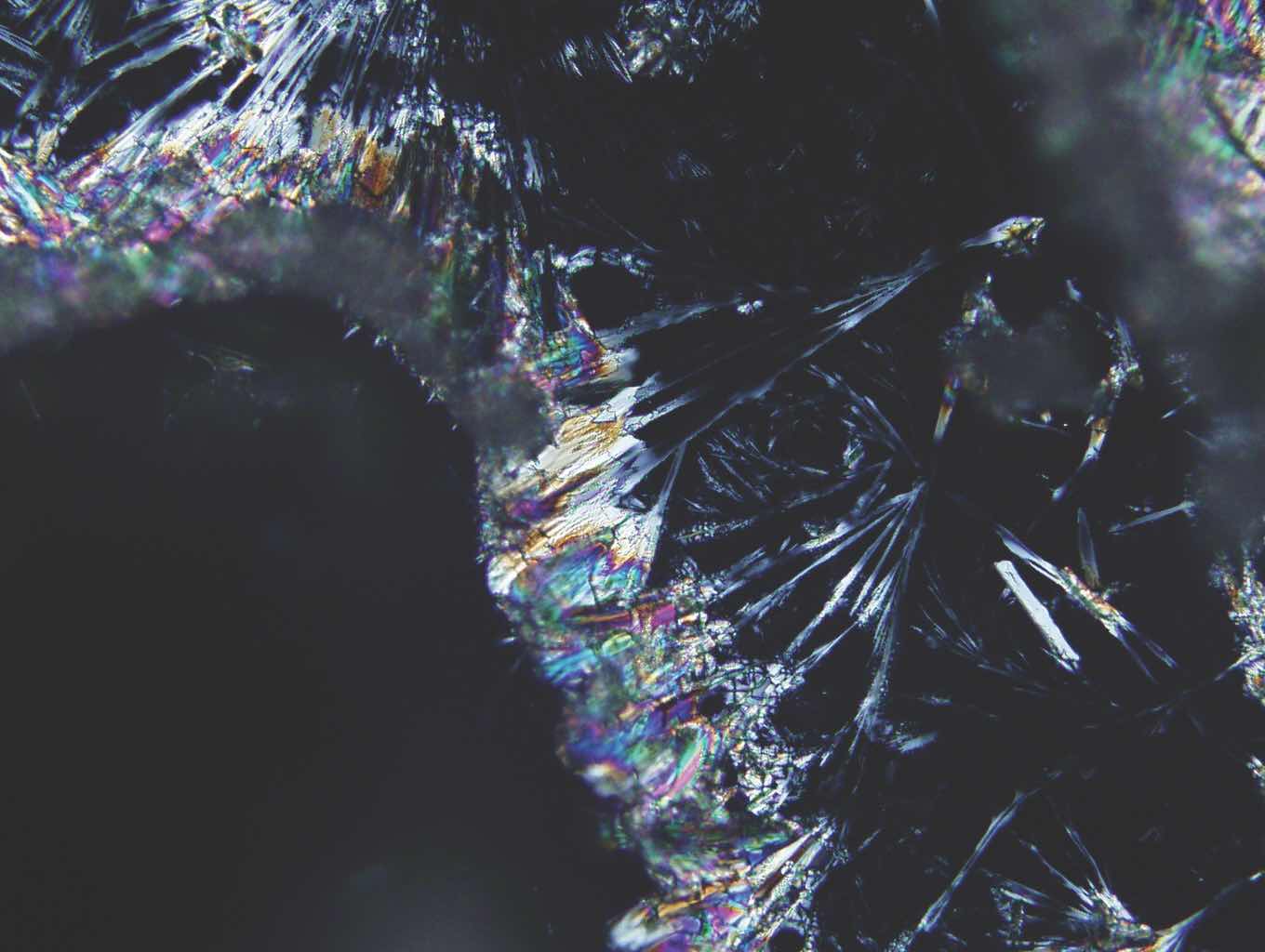

As concrete hardens, the reaction between water and cement generates chemical by-products, which reside in the capillaries and pores of the matrix. When crystalline waterproofing materials are applied, the by-products of cement hydration and crystalline chemicals produce a reaction with very dense, non-soluble crystal formations. This crystalline formation will only occur where moisture is present, forming in the pores, capillary tracts and shrinkage cracks of the concrete—the same routes susceptible to water ingress. Chemical diffusion can carry these crystalline materials deep into the concrete, plugging the voids in concrete and becoming an integral, permanent part of the structure.

In lieu of penetrating from the surface as seen with a coating application, adding waterproofing chemicals to the concrete at the batch plant ensures that the crystalline formation occurs uniformly throughout the slab or structure. In addition, by adding crystalline chemicals directly to the concrete mix at the time of batching, the same crystal growth and waterproofing functions take place in a quicker, more cost-effective manner because labor associated with a surface treatment application is eliminated. Procedural sequence for addition will vary according to the type of batch, plant operation and equipment. For most mixtures, the dosage rate of integral crystalline waterproofing admixture is 1-2 percent, based on the amount of cementitious material in the mix.

SILANE & SILOXANE WATER REPELLENTS

The use of a waterproofing coating can be undesirable in some cases due to aesthetics or the desire for a simpler application process. Certain concrete applications do not need to be fully waterproofed, but instead can function properly with a water repellent treatment, such as silane and siloxane.

Derived from the silicone molecule, silane and siloxane create an envelope of protection that can extend the life of substrates even in difficult environments. Both are UV stable and highly wear-resistant; reduce efflorescence and freeze-thaw damage; and, permit the substrate to breathe—in turn allowing interior moisture vapor to escape. Performance sealers can be used to impart water repellency to a variety of porous substrates, including cast-in-place or precast concrete.

Silane and siloxane sealers reveal little to no change in the appearance of the substrates to which they are applied. There is no gloss, color change or hiding of the substrate underneath. This is important when water protection is required for architectural finishes where a waterproofing coating would hide the decorative feature. While silanes and siloxanes provide excellent water repellency to surfaces, each has its own performance differences.

SILANE-BASED WATER REPELLENTS

Corrosion and scaling due to exposure to salt spray and chemical deicing products is a primary cause of concrete deterioration. Silane-based sealers provide an extremely effective solution to prevent deterioration from water and salt. Silanes penetrate deep because of their extremely small molecular size and ability to chemically bond with silica to form a permanent attachment to the water-repellent molecule. This creates a deep hydrophobic layer that prevents water and waterborne contaminants from entering the substrate and causing premature deterioration, while simultaneously leaving the surface with a completely invisible finish and providing a chemical “screen” that prevents chloride ions from reaching embedded steel in concrete.

Once applied, silane water repellents penetrate into the substrate and react chemically with calcium hydroxide to form a hydrophobic, water-repellent resin within the pores and on the surface. In order for this chemical reaction to take place, the substrate must be alkaline (high pH) and contain calcium hydroxide. Because silanes do not change the skid or slip resistance of concrete, they are ideal for surfaces such as walkways, bridges and roadways. Silanes are not effective in sealing other substrates such as natural stone, clay, brick or wood.

Because silanes consist of smaller molecules than siloxanes, they will typically penetrate deeper than siloxanes and thus perform better on dense surfaces such as cast-in-place and precast concrete. A consequence of this molecular size is that silanes are quite volatile. Therefore, the solids content of a silane water repellent should be high enough to compensate for the evaporation of reactive material during application and curing.

SILOXANE-BASED WATER REPELLENTS

Siloxanes have a slightly larger molecular structure and are somewhat effective on substrates up to medium porosity, such as heavyweight, smooth-faced and concrete block. Despite being closely related, the siloxane-based chemical composition does not encourage rapid evaporation. The solids content and cost of a siloxane-based sealer is typically lower than that of silanes.

Unlike silanes, siloxanes are not dependent on substrate pH to react. They can react with atmospheric moisture, as well as any moisture in the substrate, to form the hydrophobic resin. For this reason, siloxanes are ideal for treating non-cementitious building materials such as brick, stucco and stone.

Jennifer Crisman is Director of Marketing Services at The Euclid Chemical Company, a leading manufacturer of specialty concrete and masonry construction solutions. A 20-plus-year industry veteran, she manages the marketing communications activities for Euclid’s expansive line of admixtures, fiber reinforcement, concrete repair products, flooring materials and decorative concrete systems. To learn more, visit www.euclidchemical.com.