Integration of data AND business process empower freedom of choice in a concrete technology ecosystem.

The Walt Disney Co. is a world champion of vertical capture. The company’s theme parks offer families a complete package of entertainment, dining and lodging. Yet in Orlando, Fla., many visitors choose to complement or even skip Disney World for other cool things like Comcast’s NBCUniversal Studios, The Wizarding World of Harry Potter, SeaWorld and hundreds of other independent attractions, restaurants and hotels.

The independent ecosystem in Orlando that was built up around Disney’s jealously guarded vertical market has helped raise the fortunes of everyone involved. Visitors can seamlessly choose and move to whatever á la carte option they determine is the best experience and the best value for their stay.

What does this have to do with technology in the ready-mix concrete area? Lots.

Currently, there are dozens of innovative, young tech companies offering a range of products and services for our industry. They span from basic blocking-and-tackling for operations to artificial intelligence (AI). Much like the hospitality landscape in Orlando, their á la carte offerings have become part of the “concrete technology ecosystem” to enhance value and user experiences.

However, for these independent products to work, you must be able to feed them data—and lots of it. This can only be done with integration—your legacy technology providers must allow third-party access to the operational data pulled by their systems.

THE NEED FOR DATA INTEGRATION

Consider the age-old struggle to optimize mix designs. Among the several young AI companies making huge progress are Concrete.ai (see sidebar) and Giatec, which also offers in-situ sensors for concrete curing. They cannot operate independent of the concrete technology ecosystem. If the AI tools are to stand a chance at creating a practical mix optimization that reduces cost and carbon footprint, they need to tap into millions of batch records and results in general from batch systems and thousands from any particular plant.

In terms of plant optimization, Marcotte Systems is developing an AI-assisted batch controller. The goal is to run a plant “lights out”—more accurately and without costly mechanical changes. Exhaustive data needs to flow throughout the enterprise, which in this case means quality control and dispatch-to-batch information.

On the other hand, there are several exciting new offerings that track data to transform trucks into mobile manufacturing platforms. CiDRA accurately captures real-time air and other key measures of a batch in transit. Digital Fleet and Coretex (now EROAD) offer numerous reliable sensors on top of a modern communication platform. To make use of the information they gather, these products need to communicate with other systems in the concrete technology ecosystem.

HOW TECH TOOLS SHARE DATA

Thankfully, the modern technical world of SOA (service-orientated architecture) is built on easy, reliable data flow between systems, regardless of provider. SOA and SaaS (software as a service) are the underpinnings of the modern cloud-based web, and essential for any modern technology provider.

In the world of quote-to-cash, for instance, there are new options for our industry’s vertical ERP, which we have historically called dispatch. BCMI Corp. has been leading the way to the cloud and modern, mobile functionality that allows data integration with non-BCMI solutions. (Full disclosure, the author of this article is an owner of BCMI.)

CONCRETE.AI LEADS IN EMISSIONS TRANSPARENCY

Last year, a journalist from The Economist said sustainable finance is rife with greenwash—the practice of claiming misleading or unverified environmental benefits. Greenwashing can include leveraging “carbon offsets,” like land restoration or tree planting, to compensate for emissions used elsewhere but in reality do nothing to reduce a company’s carbon footprint. The article called for more disclosure. Alex Hall, CEO of Concrete.ai, could not agree more.

Conceived by leading materials scientists from the University of California, Los Angeles and run by serious citizens of our industry, Concrete.ai is committed to complete transparency. The data science company is working with one of the largest greenhouse gas (GHG) registries to provide certification for carbon credits for our industry. They are using blockchain technology to provide absolute proof of carbon avoidance.

While the certification is difficult and will take considerable time and money to complete, Hall is convinced it is the right choice for sustainable concrete production. Many responsible yet high-carbon-producing industries, like airlines and cement manufacturing, have goals for net zero carbon by 2050. They all want to get emissions as low as possible, but Hall says that won’t be good enough. They will have to purchase carbon credits, which must be transparent and certifiable.

Industries like ours must choose which carbon credits to use. Avoidance is squishy, because there are loopholes, some of which The Economist clearly points out. Concrete.ai is committed to crystal clear transparency working with blockchain technology and GHG registries.

SHARED WORKFLOWS ARE EQUALLY IMPORTANT

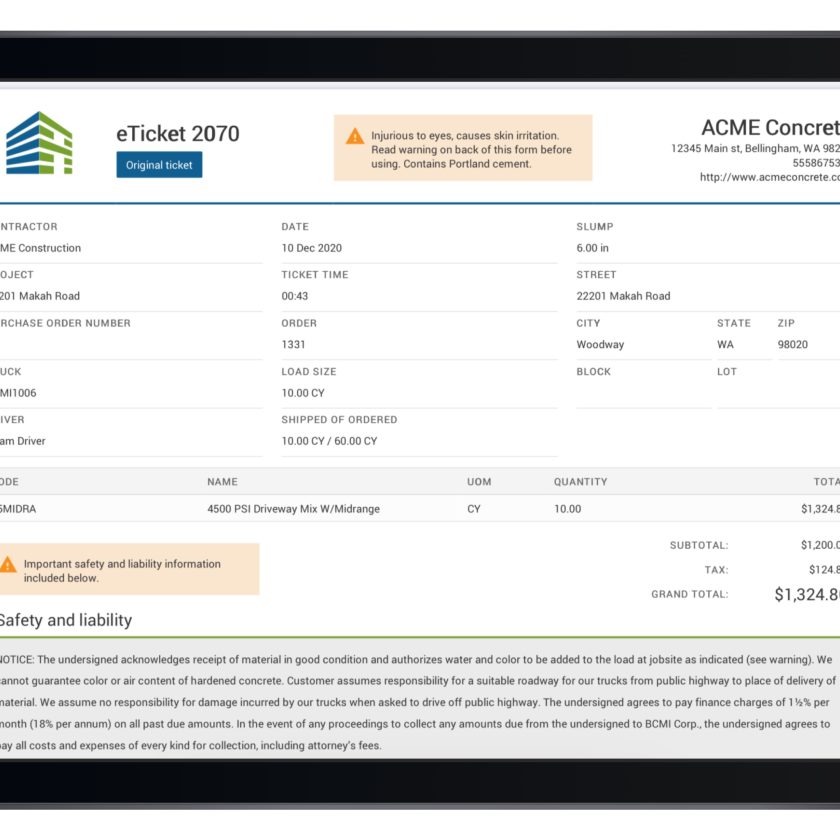

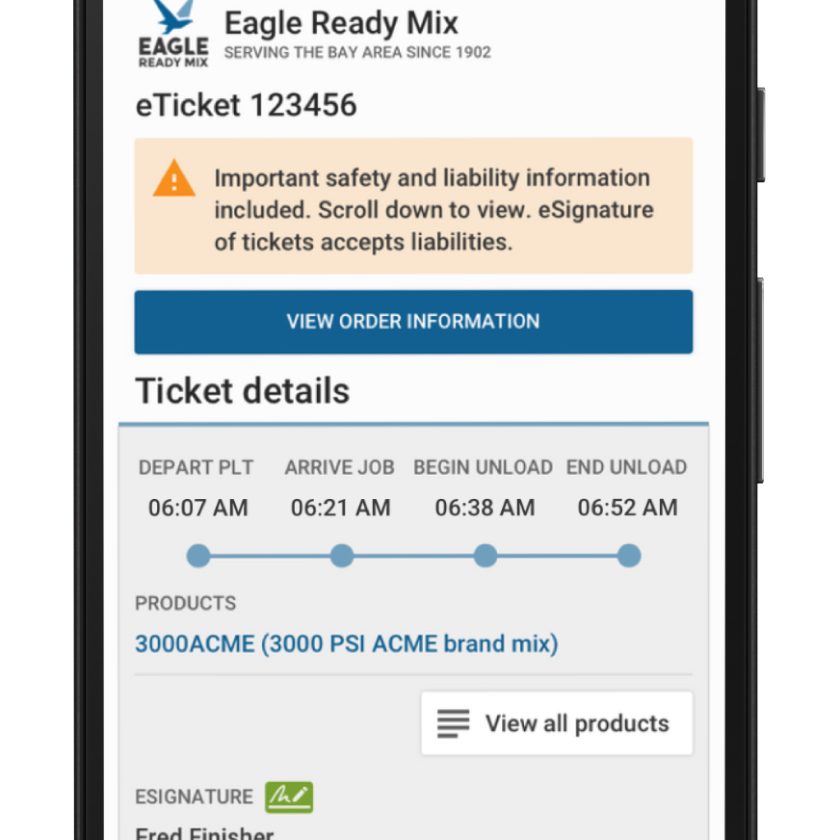

While the flow of information between systems is important, there is another key ingredient to unleashing the value of all these independent, restlessly innovative tech partners: a shared business process. Complementary systems work better with a shared workflow. For instance, in the new world of electronic ticketing and signatures, the technology requires real-time data to not only flow from all systems, but also to be organized and distributed to all stakeholders. This includes operations, sales, management, finishers, infrastructure owners and dozens of other systems that you or your customers or your material providers operate.

Consider that the eTicket should be sent to the finisher’s mobile phone, the driver’s in-cab tablet and the infrastructure owner’s tracking system, all of which may need to interact with any part of the process. The driver needs to communicate manual water add and other information. The finisher needs to communicate tweaks in the mix or changes in spacing. The infrastructure owner needs to inspect batch weights and possibly request changes or reject a load. All this can only happen in real time if the various technology providers synchronize a common communication and data input process.

Walt Disney had some good advice for all of us: “The way to get started is to quit talking and begin doing.” Modern technology providers are embracing the philosophy of SOA and SaaS by offering tools that easily integrate with third-party solutions. Start “doing” by pushing your current and future technology partners to respect your choice to share the information their products gather from your company. It’s your data. It’s your money. It’s your future.

Craig Yeack has held leadership positions with both construction materials producers and software providers. He is co-founder of BCMI Corp. (the Bulk Construction Materials Initiative), which is dedicated to reinventing the construction materials business with modern mobile and cloud-based tools. His Tech Talk column—named best column by the Construction Media Alliance in 2018—focuses on concise, actionable ideas to improve financial performance for ready-mix producers. He can be reached at [email protected].