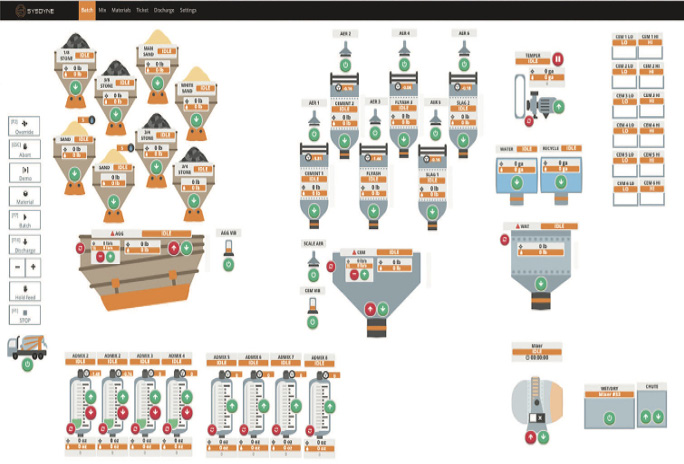

Sysdyne

The latest Pioneer Cloud batch control system takes advantage of cloud computing technology to minimize batch personnel and improve efficiency. Designed and developed as an integral part of Sysdyne’s ConcreteGO Cloud dispatch, it updates inventories in real-time with material usage and documents receipts. Pioneer users can access batch plant controls anywhere, anytime by logging onto the ConcreteGO.com portal, maintaining consistency of the mix designs between dispatch and batch without manually downloading. The system breaks the “silo” and brings batch plant operation visibility, enabling ready mixed producers to quickly identify problems, such as overuse of cement, and take immediate action. — Sysdyne Technologies, Stamford, Conn., 877/797-3963; https://sysdynetechnologies.com

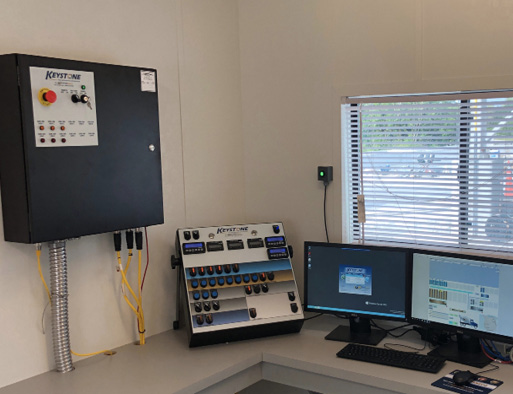

GivenHansco

Keystone Batch offers a compact, quality and easy-to-use system suiting concrete plants of any size. It provides the accuracy, consistency, and efficiency to meet all customer demands and exceed batch plant operator expectations. Users have constant and instant knowledge of load status, and remain in complete control of every order, even at remote batch sites. The batch interface is easy to understand and includes elements on the screen that are color coded by groups such as admixes, water, cements, and aggregates. Loads are tracked from weigh-up to discharge with easy-to-read graphical displays and numeric readouts.

Keystone Batch is highly configurable and customizable based on plant operator needs. It provides personalized visuals that adjust while users batch, displaying accurate aggregate, cementitious material, and admixture inventories. Sequencing of materials is easily adjustable and can be modified to be added at any point during the load. — GivenHansco Inc., Columbus, Ohio, 614/310-0060; www.givenhansco.com

Jonel

Company cites five-plus decades of reliability, flexibility and customization in concrete plant controls. Jonel engineers can tailor panel and control solutions for almost any style of operation, from basic transit mixed to large scale custom plants. Each system is designed from the ground up to scale the needs of the most demanding concrete operation. Using state of the art symmetrical processing, Jonel offers one of the most responsive, accurate, extensible reporting and open application interfaces to allow concrete producers to easily report on critical plant performance, batching analysis and inventory control. — Jonel Engineering, Fullerton, Calif., 800/432-4567; www.jonel.com