As the architectural/engineering/construction community looks to achieve ever more energy-efficient homes and buildings, especially in an age of net zero classification, Owens Corning has crafted a solution for concrete block walls with manufactured stone veneer or face brick.

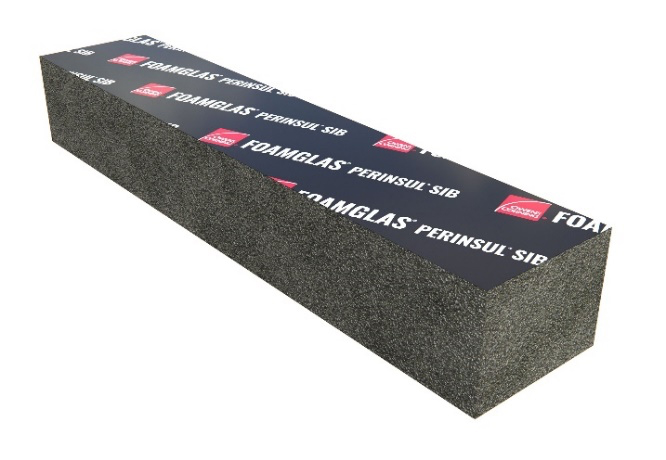

Company engineers bill Foamglas Perinsul SIB as a thermal bridging solution for high-performance buildings. Material science helps explain the thermal function: Foamglas Perinsul SIB is made of cellular glass, enabling it to help eliminate thermal bridging beneath exterior masonry veneer walls. Product developers note that the thermal bridge near the foundation has historically been difficult to address due to the need for an insulating material that could meet both structural load and thermal performance requirements.

By achieving a continuous thermal barrier in various types of wall assemblies, Foamglas Perinsul SIB protects against energy loss at critical junctions. Cellular glass affords impressive compressive strength and dimensional stability. To help protect against moisture, cellular glass insulation is nonabsorbent; impermeable to water; and, will not shrink, compress or deform over time—even in extreme temperatures. The material has long been trusted to defend against thermal bridging in high-performing buildings in Europe.

Foamglas Perinsul SIB’s compressive strength contributes to a robust insulating material that is lightweight and easy to install. The product can support masonry veneer wall loads for low-rise buildings, free of deflection. Sizes match those of standard masonry blocks and are intended to abut end-to-end with no vertical mortar. Once installed, Foamglas Perinsul SIB is designed to last the life of the wall and maintain its thermal efficiency. — Owens Corning, Toledo, Ohio; www.owenscorning.com/foamglas