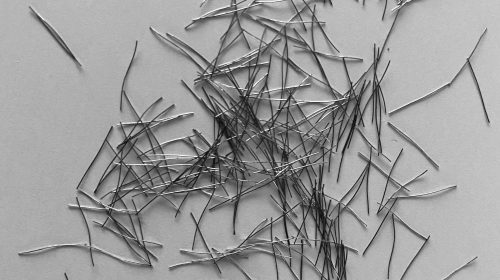

CFS 300-Series carbon steel fibers are designed exclusively for use in ultra-high performance concrete applications, including transportation infrastructure. Fabricated in respective 13-, 19.5- and 25-mm lengths, the 0.3-mm diameter CFS 313-1, 319-1 and 325-1 Type I fibers meet the Federal Highway Administration Buy America requirements for federally funded projects.

Steel fibers control cracking by meeting micro cracks where they originate, unlike rebar, which only reinforces a single plane and therefore allows cracks to grow until they meet that plane. CFS 300 Series fibers help protect against traffic wear and harsh elements and ultimately extend the projected concrete service life. In addition to compressive strength in the 20,000 psi range, steel fiber-dosed UHPC exhibits tensile ductility and durability comfortably exceeding conventional or high performance concrete.

“The use of UHPC in bridges and roads is quickly setting a new industry standard, and we’re thrilled to introduce our 300-Series fibers to meet those specifications and comply with the Buy America Act,” says Concrete Fiber Solutions Manager of Engineering Services Mike McPhee. “Traditional concrete reinforcement methods simply can’t measure up to the protection fibers provide; less shrinkage and cracking to the concrete means the pavement lasts longer with fewer maintenance costs along the way. With today’s increased focus on infrastructure improvement, we’re proud to offer an American-made solution and partner with the engineers, contractors and departments of transportation that are working diligently to make those improvements happen.”Typically dosed at volumes up to 2 percent of a yard of concrete, CFS 300-Series fibers impart ductility in an otherwise brittle matrix, along with elastic-plastic or strain-hardening behavior in tension. They abide ASTM A820, Standard Specification for Steel Fibers for Fiber-Reinforced Concrete Type I (cold-drawn wire). — Concrete Fiber Solutions, Buffalo Grove, Ill., www.concretefibersolutions.com