Sources: Concrete-AI, Los Angeles; CP staff

First-time exhibitors at World of Concrete 2021 included an artificial intelligence and machine learning specialist demonstrating the computing and data visualization capabilities of four modules for concrete optimization and supply chain management: performance prediction, cost minimization, embodied carbon dioxide optimization, and mixture design generator. Concrete-AI has been launched as an independent entity to commercialize data, software, and algorithms developed at the Institute for Carbon Management, hosted within the Samueli School of Engineering at the University of California, Los Angeles (UCLA).

Professors Mathieu Bauchy and Gaurav Sant seek to apply pioneering manufacturing and plant automation technologies to concrete production, quality control and embodied carbon management. With recurring aggregate, binder and admixture material inputs, for example, their “performance prediction module” calculates the expected slump, shrinkage and strength development (one- to 90-day) properties. Concrete-AI artificial intelligence and machine learning algorithms analyze existing and newly logged data to predict engineering performance indicators with increasing accuracy and certainty.

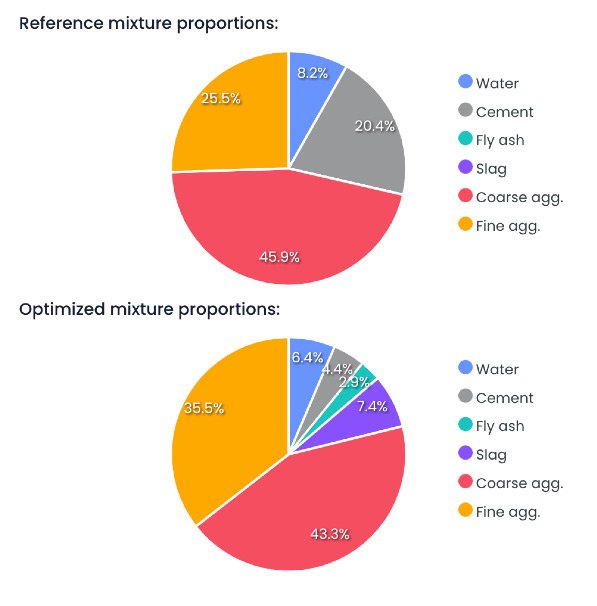

The “cost minimization module” uses raw material cost data, plus “performance module” inputs, whereby a concrete producer, engineer or contractor can compare multiple formulations to achieve mix design economy while attaining specific performance metrics: e.g., early strength, slump, and/or 28-day (or later) strength. Concrete-AI’s embodied CO2optimization module functions similarly as the cost module, although to minimize the carbon intensity of a concrete formulation that meets/exceeds all desired engineering performance variables. Moreover, it highlights carbon reduction opportunities wherein ultimate strength realization can be set at 56 or 90 days, instead of more common 28-day targets.

The Concrete-AI technology emerged from a Samueli School of Engineering effort whose members also participated in the development of a carbon dioxide mineralization and sequestration method: CarbonBuilt. That project is on its own commercialization path via an independent entity, CarbonBuilt Inc., which was the Grand Prize Winner of the NRG COSIA Carbon XPRIZE, global competition that ran from 2016 until 2021. — www.concrete-ai.com

EMBODIED CARBON DIOXIDE OPTIMIZATION

Related articles

CarbonBuilt and CarbonCure teams take $20M global competition